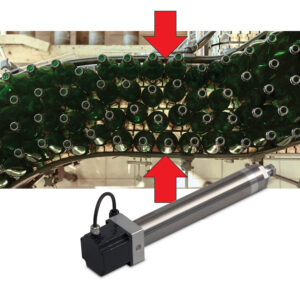

Side Guiding

Product Family: Electric

Product Used: ERD15 Stainless Steel Actuators, Special Epoxy-coated Stepper Motors

Product Type: Standard / Special Stepper Motors

Application Description:

Side guiding, lane adjustment and automating product changeover in beverage production.

Challenge:

A conveyor manufacturer needed an electric solution to reduce product change-over time and eliminate operator adjustment error. Without a programmable solution, their customers were limited by cumbersome manual adjustments whenever changes were needed. They were also experiencing some side guide position “floating” due to pressure fluctuation in air supply. IP65 ingress protection was also a requirement. The manufacturer had already standardized on Rockwell Automation AB PLCs.

Tolomatic Solution:

Two stainless steel ERD15 electric cylinders, were used for each side-guiding plate. Tolomatic installed special motors with epoxy coating to comply with requirement for IP65 protection. A JVL drive provided seamless communication with the AB controls. The JVL drives were daisy-chained in series to simplify communication cabling. ACS drives were daisy-chained in series to simplify communication cabling.

Customer Benefit:

- Change-over time reduced from 6 hours to a few minutes, for an immediate return on investment.

- Position was held and tracked constantly, eliminating adjustment errors.

- Programmability for future system expansion.

- Eliminated pneumatic maintenance and downtime while increasing energy efficiency for reduced operational cost.

CONV-012-E

Kontakt zu einem Ingenieur

Kontakt zu einem Ingenieur