- Home

- Unterstützung

- Häufig gestellte Fragen

- Energieübertragung FAQs

Energieübertragung FAQs

This section is for frequently asked questions regarding Tolomatic’s power transmission products. If you have a question not covered here, feel free to reach us at 1-800-328-2174 or help@tolomatic.com

How much shaft load (weight) can a standard series Float-A-Shaft® handle?

Zero or No side load weight should be applied to the bores when using any gearbox FAS or SRG.

How often do you need to lubricate the Float-A-Shaft® or SRG?

Here’s the amount (by volume) of grease required when assembling various SRG units:

- 1:1 Compact…1.2 oz total (0.3 oz @ 4 positions 90deg apart)

- 1:1 Standard…3.2 oz total (0.8 oz @ 4 positions 90deg apart)

- 2:1 Standard…2.4 oz total (0.6 oz @ 4 positions 90deg apart)

- 3:2 Standard…2.8 oz total (0.7 oz @ 4 positions 90deg apart)

FAS Compact

Before initial use, a compact FAS should be filled with 0.35 oz. (by volume) of grease.

Additional greasing is a little subjective and is dependent on how the FAS is being used.

- Continuous & Heavy Duty use: add 0.1 oz. (by volume) every 1½ month

- Intermittent & Light Duty use: add 0.1 oz. (by volume) every 3 months

- Minimum use: add 0.1 oz. (by volume) every 6 months

Why does the catalog list static holding torque as lower than dynamic torque?

Static Torque vs. Dynamic Torque

When it comes to brake calculations, it is important to be conservative and to always err on the side of caution. All brake materials rely on the coefficient of friction between themselves and their mating surface to perform the braking function. A consistent coefficient is reliant on the two surfaces being properly “mated” together i.e. removing the high and low points of each surface so as to get the most consistent contact surface. Proper mating of these two surfaces requires “burnishing”. Until burnishing is performed the highest coefficient cannot be reached. Burnishing is the process by which the brake is applied dynamically with its mating surface (in this application it would be the disc) thus removing any inconsistencies between the two surfaces.

Burnishing also provides another aspect affecting the coefficient of the two materials. Burnishing creates heat. This heat changes the make-up and structure of the surface of the brake friction material providing a higher frictional coefficient. Burnishing, between removing the “highs” and “lows” and the effect of heat on the friction material will give the highest frictional properties in the application.

Not all brake applications are dynamic. In fact, many are never applied dynamically and therefore never achieve the benefit of burnishing. For this reason, Tolomatic states both static and dynamic torque performance values. Tolomatic defines static torque as 50% of dynamic torque to ensure adequate braking in those applications where burnishing never occurs.

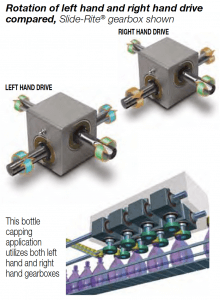

What is the difference between right hand and left hand gearboxes?

Using the grease port as a reference point. See below the rotation of right hand and left hand. Top bore and bottom bore turn the same direction it’s a “RH” right hand turn. If they turn opposite of each other then they would be “LH” left hand.

What is the amount of backlash expected from a Float-A-Shaft® or SRG?

The backlash on a standard size Float-A-Shaft gearboxes range from 3 to 5 degrees of backlash. The compact Float-A-Shaft gearboxes range from 2 to 4 degrees of backlash. All of our Slide-Rite gearboxes have a backlash of 1 degree or less.

What type of hydraulic fluid can be used in Tolomatic hydraulic calipers?

There are two types of hydraulic fluid used in brake calipers. DOT Automotive and Mineral Based. Tolomatic offer EPR seals for automotive based fluids and Buna-N Seals for Mineral Based fluids.

How do I mount my brake?

For double acting brake calipers customers provide their own mounting bracket using the long shoulder bolts that hold the caliper together. Tolomatic does supply mounting brackets for single acting brake calipers. Please contact Tolomatic Applications Engineering for further questions on brake mounting. 763-478-8000

What is the difference between double and single acting brake calipers?

Double acting calipers have pistons on either side of the brake caliper and when activated will center on the disc so the disc can be mounted in a fixed position. Single acting brake calipers have one piston on one side of the brake caliper while the other is the „dead side“. Single acting brake calipers need to move side to side when activated in order to center up on the disc.

Does the hub and quick disconnect need to be ordered separately?

Both hub and quick disconnect can be ordered with the disc or separately.

Kontakt zu einem Ingenieur

Kontakt zu einem Ingenieur