10 tips for specifying electric rod actuators: Part 2

By Tolomatic on September 19, 2017

In many applications electric rod actuators are a great solution. Compared to pneumatic or hydraulic cylinders, electric linear actuators offer more control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often the superior actuation choice.

parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often the superior actuation choice.

Specifying an electric linear actuator is easier when you use our selection tips. For a more thorough look at them, download our whitepaper. For a quick visual reminder, print our infographic.

Specifying electric rod actuators

Our recent blog explained the first five tips.

Tip #1 Know the load

Tip #2 Forget fluid-power specifying rules

Tip #3 Consider duty cycle

Tip #4 Understand your application’s force and velocity requirements

Tip #5 Avoid side-loading

Now, here are the final five selection tips.

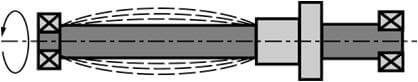

Tip #6 Obey critical speed limits

Just like speeding when driving can get you in trouble, asking an actuator to exceed its critical speed limit can lead to big problems. Critical speed is the point at which the actuator’s power screw meets its natural frequency. At this point, the screw will begin to oscillate, and the resulting “screw whip” can cause noise, premature wear, and system breakdown.

Tip #7 Match the actuator’s peak thrust to the application

Manufacturers provide thrust curve data for their actuators. Make sure the actuator’s capabilities match your application’s requirements, or the actuator won’t perform to your specifications. It may wear out early or even fail.

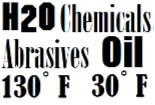

Tip #8 Consider the environment

Tip #8 Consider the environment

Heat, cold, dust, moisture, and corrosive agents all affect actuator performance. Make sure you understand the environment the actuator is going to work in. Specify the product and options that match the conditions.

Tip #9 Make room for the entire system package

An electric linear actuator’s actual length is longer than the stroke length because of “dead length” that accommodates internal components. Also, the actuator system includes a motor. Be sure to allow space for the entire system envelope.

Tip #10 Remember: motor mounting affects both system performance and size

You have two options for mounting a motor on an electric linear actuator: inline or reverse parallel (RP). RP configurations are sometimes favored because they take up less horizontal space; however, RP configurations are inefficient since they rely on a system of belts or gears to transmit the motor’s power to the actuator. Some power may be lost. Inline configurations are far more efficient but require more horizontal space.

Learn more

Our white paper on tips for specifying electric rod actuators will give you the information you need to find the right linear actuator for your application. Download it here.

Ask an Engineer

Ask an Engineer