Go electric!

By Ryan Klemetson on June 2, 2021

Plug in to electromechanical actuators for new—and better—performance

In the world of automation technology, a new type of linear motion technology is taking the stage. Electromechanical actuators are headlining as a viable alternative to hydraulic cylinders, even for high forces. Electric actuators can provide superior performance over hydraulic cylinders—through improved precision, flexibility and reliability.

Our new e-book summarizes the whole concept of “why electric?” We compare hydraulic and electric technologies, and provide important tips for converting and review a couple of applications.

Download our e-book and use it as a ready reference.

Here are a few of the concepts and ideas we cover:

Hydraulics—No longer the only option

Hydraulic cylinders are workhorses, and they aren’t going away. Hydraulics can do some things that electrics can’t do, power density being one. But they do present some drawbacks, among them oil leaks, noisy power units, large footprint, manual changeovers, and susceptibility to temperature fluctuation.

Benefits of electric linear motion systems

Motion control flexibility is the main reason engineers choose electric over hydraulic systems. Electric actuators, coupled with a servo drive and motor, have infinite control over all aspects of linear motion. The levels achieved for improved speed, position and thrust are far beyond the capabilities of a hydraulic system.

Electric actuators are generally unaffected by temperature fluctuations, they require little or no maintenance, and they typically operate in the 75 to 80 percent efficiency range, compared to hydraulics, which operate in the 45 to 55 percent efficiency range.

How much do electric systems cost?

Electric servo systems can cost more to install than hydraulic systems. But that’s not the bottom line. Electric systems operate more accurately, flexibly, efficiently and with little or no maintenance over the life of the system. As a result, their total cost of ownership is lower over the life of the equipment — making them an attractive alternative to hydraulics.

Sizing and converting tips

Converting a hydraulic cylinder to an electric actuator system requires understanding three key variables: force, motion profile and electric actuator technology.

Over-sizing a hydraulic cylinder is common due to the relatively small effects it can have on the overall cost of the system. This is not the same with electric actuators. Their costs can be affected significantly when too much safety margin is built into the design. The biggest mistake is to oversimplify the force calculation process.

Calculating using the system pressure method results in an over-sized, over-priced electric actuator solution.

System pressure method: Not recommended

Force = area of the cylinder x rate system pressure

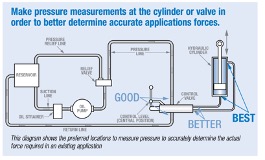

In general, there are three different areas on a hydraulic system to take pressure measurements. The closer you can get to the point of work, the more accurate your measurement.

Conservative measurements get you close. Accurate measurements get you where you need to be so that actuators and motors aren’t undersized or significantly oversized.

When sizing hydraulic cylinders, it may only cost a few hundred dollars to oversize by selecting a larger bore size for more force. However, oversizing an electric actuator—by using double or triple the required force capacity— can add thousands of dollars of unnecessary cost to the system. That is why proper measurements are key to right-sizing electric actuator systems.

Application example: Converting a tube-bending machine

Tube-bending machines have been driven by hydraulics for 80 years. Sure, there’s a little waste, but this is the way it’s always been done. Why change now?

What if there’s a better way?

The fundamental reason to consider changing to an electro-mechanical system is because electric actuators make better parts than hydraulics. By “better,” we mean less waste and tighter tolerances. And we do that through force feedback, which tells us how hard the actuator is pushing and then coordinating the move with force and position.

When used for electric resistance welded tubes (ERW), a low cost type of steel tubing, an electric system will allow tighter tolerances—and less waste—because force feedback allows the machine to adjust the actuator stroke for each bend. Testing identifies various combinations of seam location and how much force is required to bend the tube to the correct position for that seam location.

Force feedback, used to compensate for tolerances in wall thickness and the welded seam location, can help a machine designer reduce scrap by 80 percent.

The times may be changin’—and maybe for the better!

There’s more!

Our new e-book is also a ready resource for online resources ranging from guides, white papers and videos to sizing and selection, including motor selection.

Download the e-book.

And, you can always ask an engineer. Need to convert your hydraulic system to electric linear motion? Discuss your application with us and Start the design process.

Bob Dylan photo: Diana Davies/Courtesy of the Ralph Rinzler Folklife Archives and Collections, Smithsonian Institution

Ask an Engineer

Ask an Engineer