High-force linear actuator makes muscle car simulation possible

By Ryan Klemetson on March 10, 2020

Tolomatic linear actuators are used worldwide in a myriad of industries for automation tasks like conveying, sorting, filling and more. Beyond conventional industrial deployments, they are also used in demanding, non-industrial applications. Some of these, such as simulators for flight, driving, testing and entertainment, require high-frequency moves to create a realistic experience. Here’s one such story, in which our electric high-force linear actuators helped simulate the experience of popping a wheelie in a true muscle car.

Tolomatic linear actuators are used worldwide in a myriad of industries for automation tasks like conveying, sorting, filling and more. Beyond conventional industrial deployments, they are also used in demanding, non-industrial applications. Some of these, such as simulators for flight, driving, testing and entertainment, require high-frequency moves to create a realistic experience. Here’s one such story, in which our electric high-force linear actuators helped simulate the experience of popping a wheelie in a true muscle car.

This blog is a summary. For the full story, download our case study, Popping a wheelie: Roller-screw electric rod actuators key to simulating thrill of muscle-car drag racing.

Born to run: Dodge SRT Demon

Imagine the drag racetrack. A straight quarter mile where drivers pit some of the most powerful cars in the world against each other.  It’s an environment full of the smell of hot rubber, the flashing lights of the starting tree, and the roar of engines as cars race down the track reaching speeds in excess of 100 mph (160 km/h) in just a few seconds.

It’s an environment full of the smell of hot rubber, the flashing lights of the starting tree, and the roar of engines as cars race down the track reaching speeds in excess of 100 mph (160 km/h) in just a few seconds.

The Dodge SRT Demon was inspired by this world, with an engine powerful enough to generate 1.8 Gs off the line. That kind of force means the car can pop a wheelie (lift the front end off the ground)—a sign of a real muscle car.

This is not a car for everyone, but true motorheads are salivating for a test drive. However, the Demon’s maker, Fiat-Chrysler Automotive (FCA), didn’t want to offer a test drive to every prospective buyer. The solution? FCA hired simulator design company, Sigma Integrale, to develop two simulators FCA could take to car shows.

If you’re a motorhead, you’re probably wondering how you can score a run in this simulator. If not, you’re probably wondering how a muscle car simulator relates to industrial automation. It all boils down to being able to quickly and reliably lift the front end of the vehicle without needing regular maintenance.

Challenge: high-force, high-speed lift

Challenge: high-force, high-speed lift

The simulators were actual Demons without drive trains, positioned side by side with a video display of the track in front. Recreating the feel of accelerating in the Dodge SRT Demon was the challenge. The Demon goes from zero to 60 mph in a mere 2.3 seconds and generates about 1.8 Gs off the line.

During the simulated drag race, as the driver launches the car, the front end rises 12 inches and then drops in steps as the driver goes through the gears. The rate of rise and drop are all in proportion to driver input. When the driver brakes at the end of the quarter-mile run, the nose of the car characteristically dives and the rear end rises in response until the car comes to a stop.

Solution: RSA high-force electric rod actuators

Sigma Integrale determined that to recreate this movement, they would need four fast and powerful actuators in the suspension – two in front and two in back – to provide the necessary force and lift. It meant replacing the suspension parts with electric actuators capable of producing 2,000 lbf each and lifting the front end 12 inches in a fraction of a second. The actuators had to be compact enough to fit into the suspension space without altering the outside appearance of the car.

Sigma considered using hydraulic or pneumatic rams due to the force and speed requirements but rejected them because the engineers wanted precise control and didn’t want to manage issues that hydraulic and pneumatic systems typically have in traveling displays.

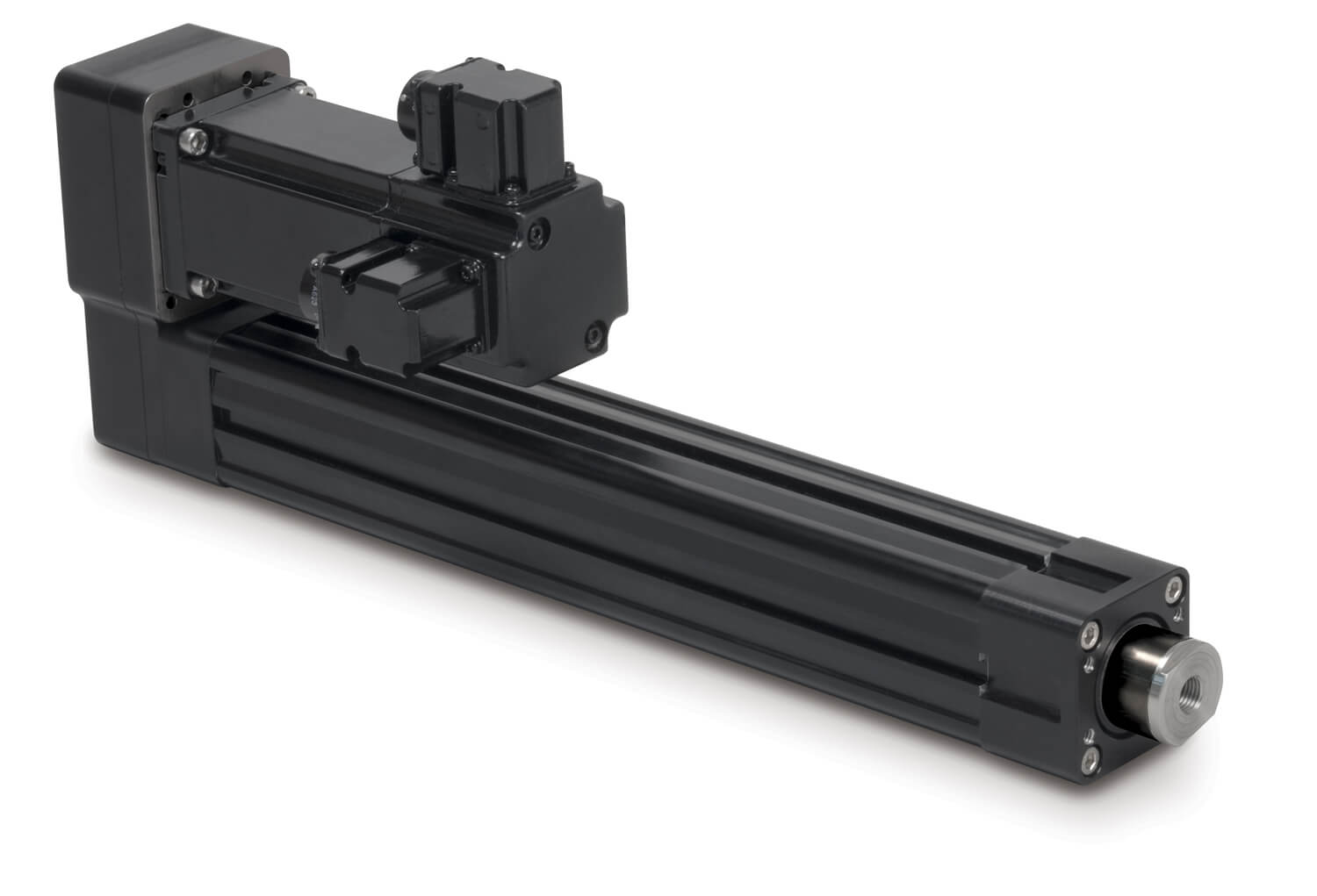

After an extensive review, Sigma selected the RSA electric rod actuator. Our engineers recommended the RSA with the roller screw option to meet the application’s force and low maintenance requirements. The RSA roller screw actuator also concentrates a high amount of force in a compact package. (In fact, roller screw actuators offer the highest force, lowest maintenance and best reliability of all electric rod actuators.)

Results: perfect performance

The RSA actuators have lifted and cycled the simulators through their runs 172,800 times — or 86,400 wheelies per car. No problems.

In summary

This was a fun project, no doubt. And well within our wheelhouse, because we are problem-solvers, and this was an exciting challenge to solve. If you have a problem, some questions or need engineering input from linear motion experts, contact us.

Read more

For the full application story, download our case study, Popping a wheelie: Roller-screw electric rod actuators key to simulating thrill of muscle-car drag racing.

Ask an Engineer

Ask an Engineer