TKS Linear Actuators

TKS precision linear actuators offer a dual profile rail with wide, low profile base ideal for XY tables/stages and XYZ systems.

The TKS precision linear actuator is designed for applications carrying moderate load and requiring high precision in parameters such as flatness, straightness and accuracy. XY or XYZ tables/stages can easily be created using TKS precision linear actuators. Two parallel profiled rails with four recirculating ball linear guides provide consistent and precise performance.

- Choice of either acme or ball nuts

- System payloads up to 90 kg (200 lb)

- 2 metric body size screw/nut combinations

- Strokes in any incremental length up to 2438 mm (96 in)

- For applications requiring a larger stage product or TKS25/75 applications, please see the TRS

Features & Ordering

TKS Features

Use the links below to locate a Tolomatic distributor in your area, find out more information on how to specify and configure your actuator, service parts information, and selection guidelines and tips.

Find a Tolomatic distributor

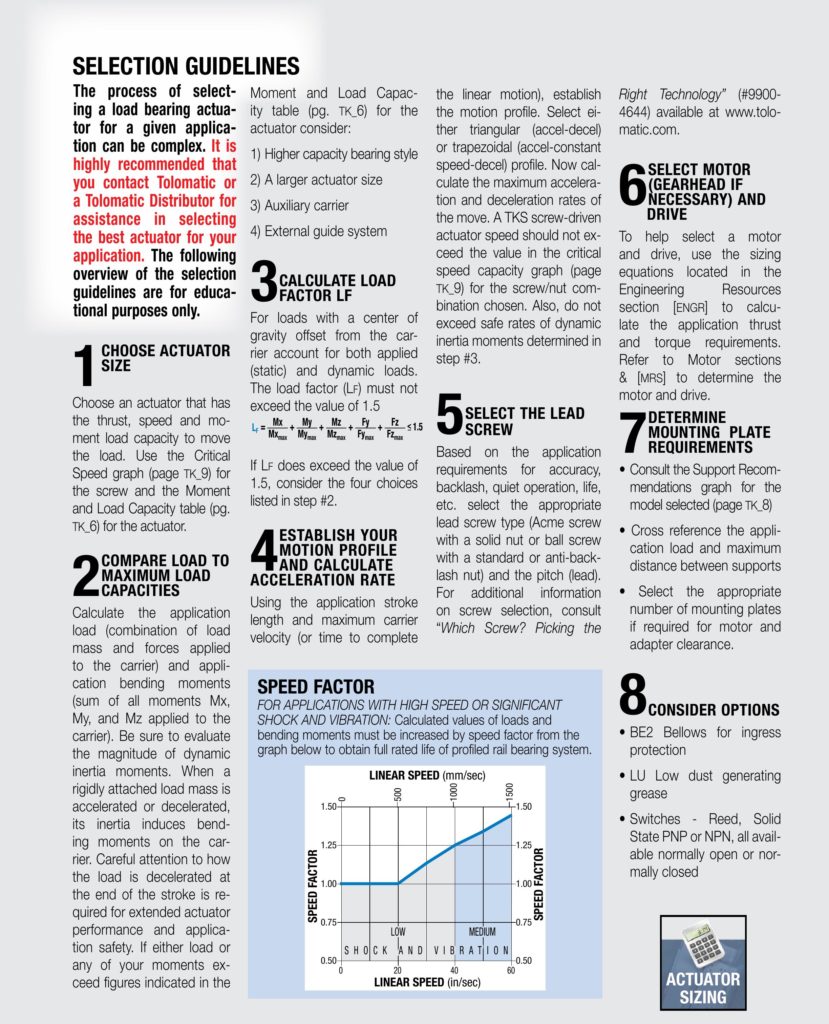

TKS Selection Guidelines

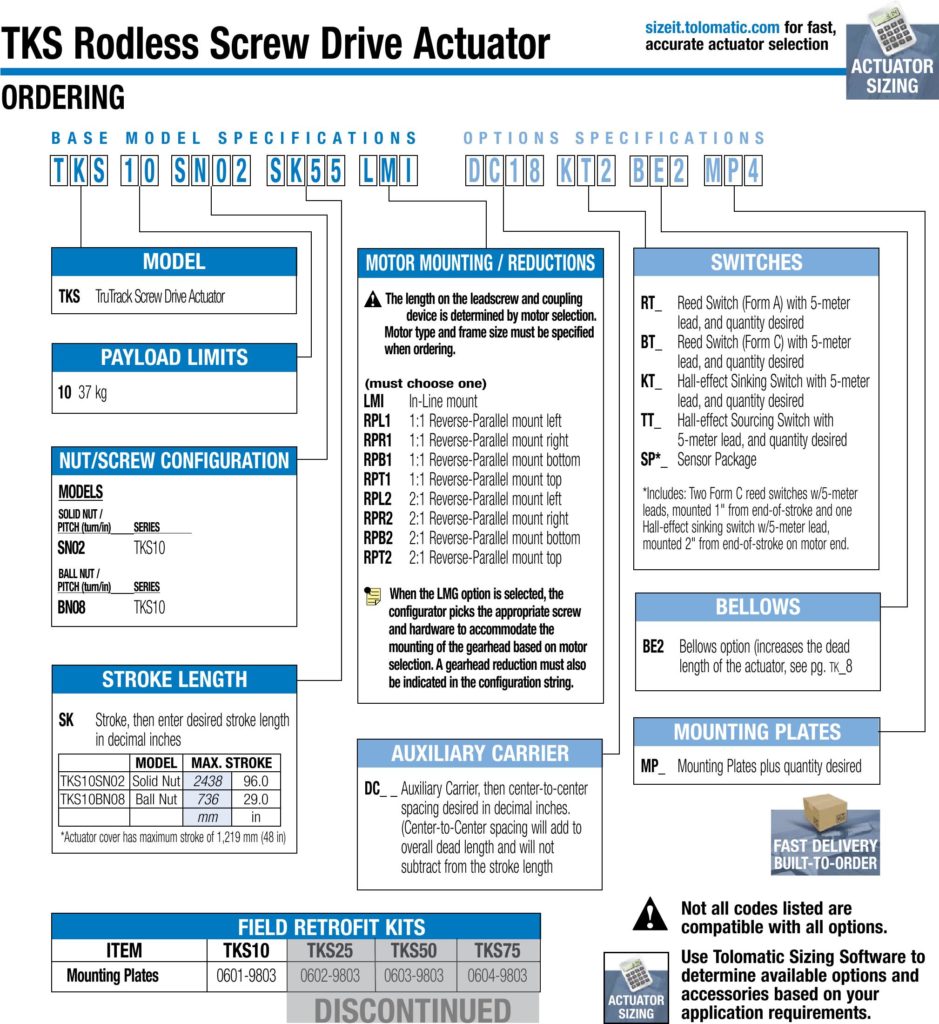

TKS Ordering

Specifications

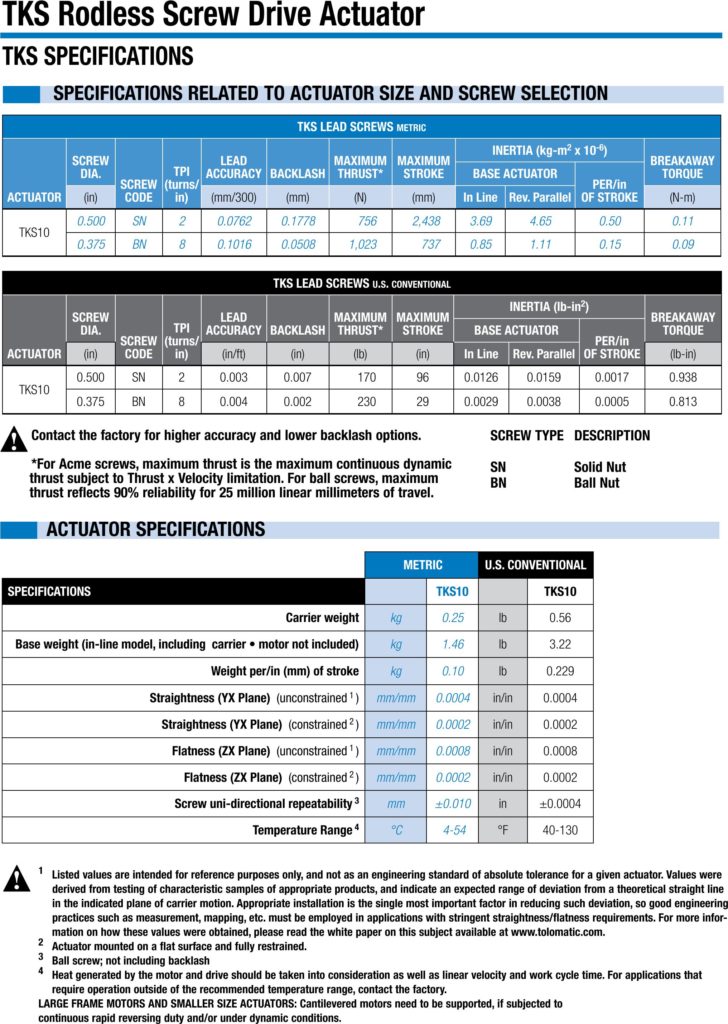

TKS Actuator Size & Screw Selection Specs

TKS Critical Speed Capacities

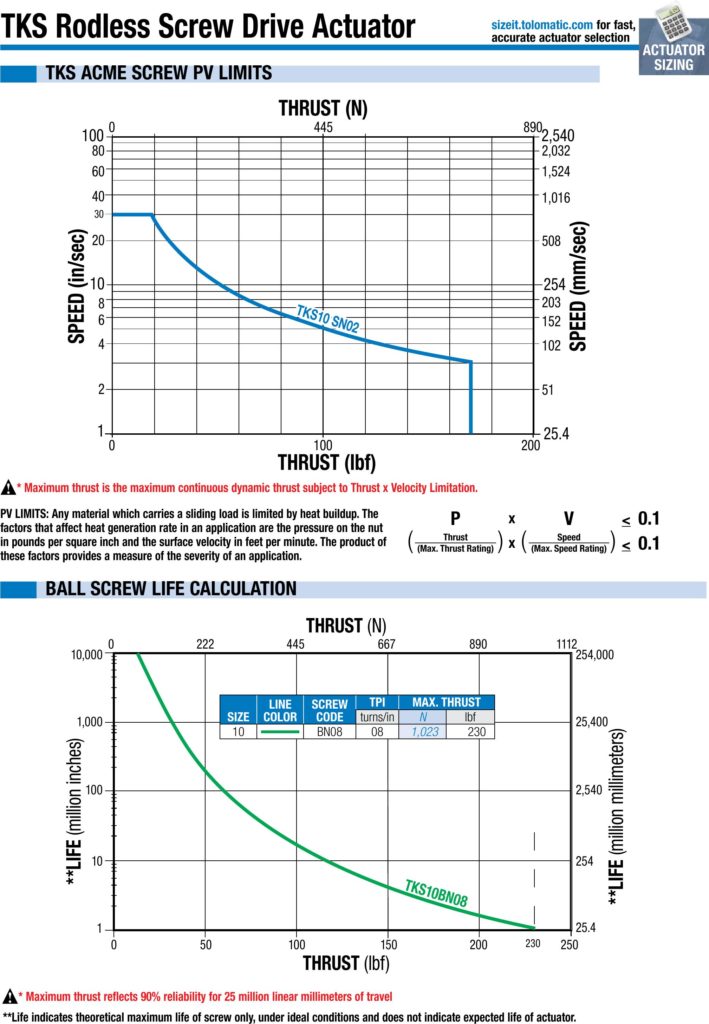

TKS Acme Screw PV Limits & Ball Screw Life Calculation

TKS Bending Moments & Loads Specifications

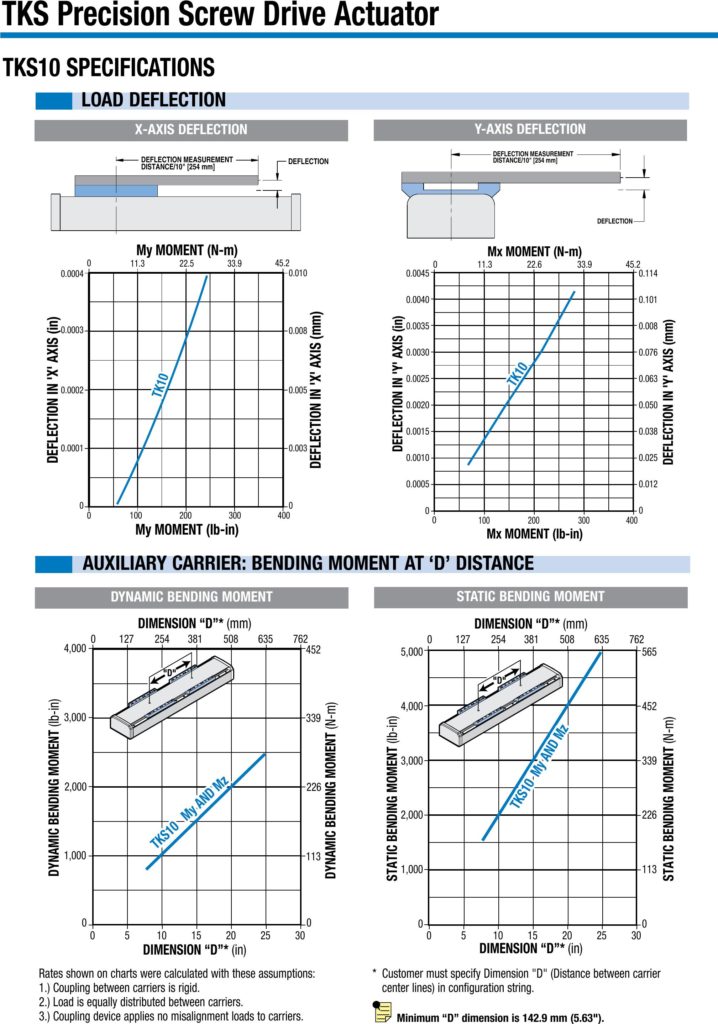

TKS Load Deflection & Auxiliary Bending Specifications

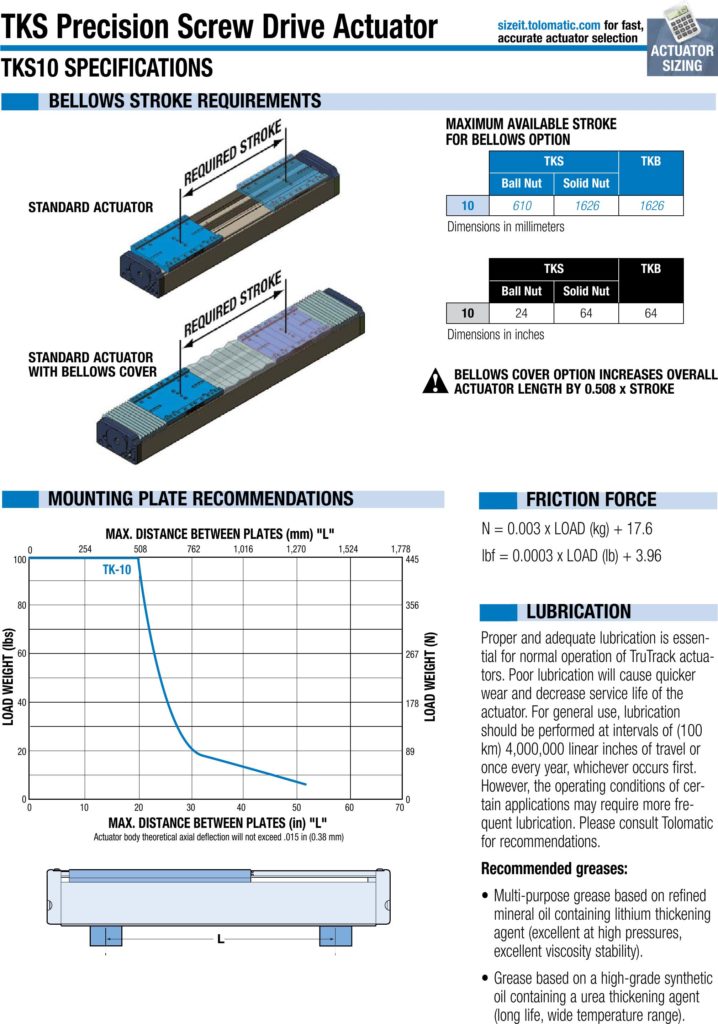

TKS Bellows Stroke & Mounting Plate Specifications

TKS Switches

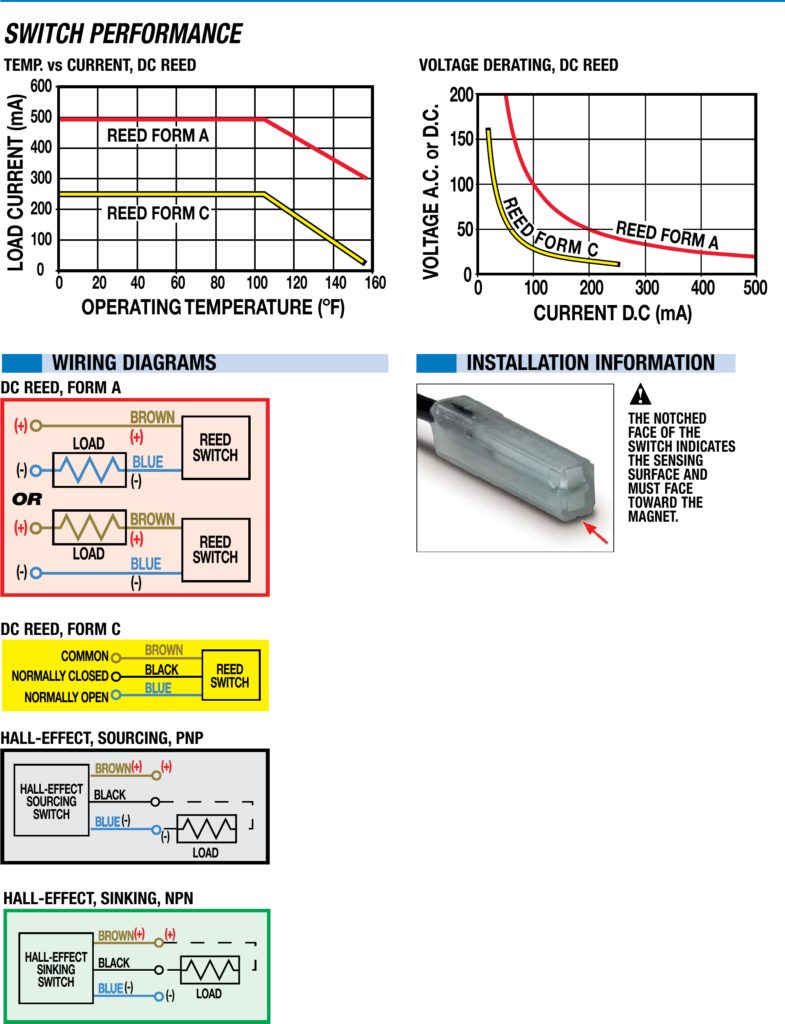

TKS Switch Performance & Wiring

Dimensions

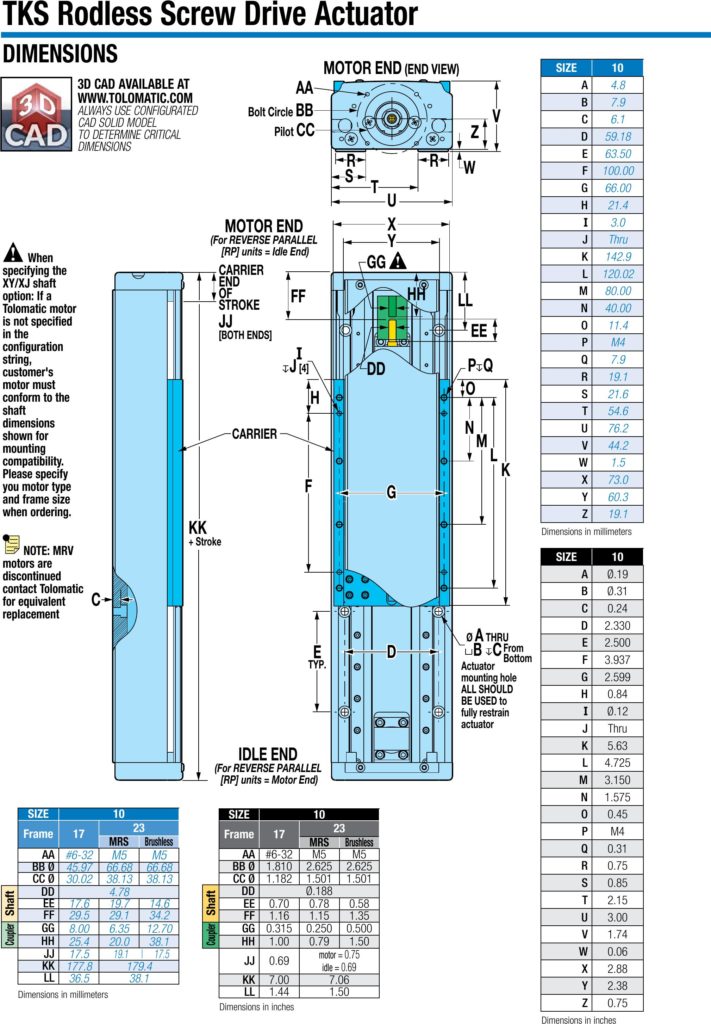

TKS Actuator Dimensions

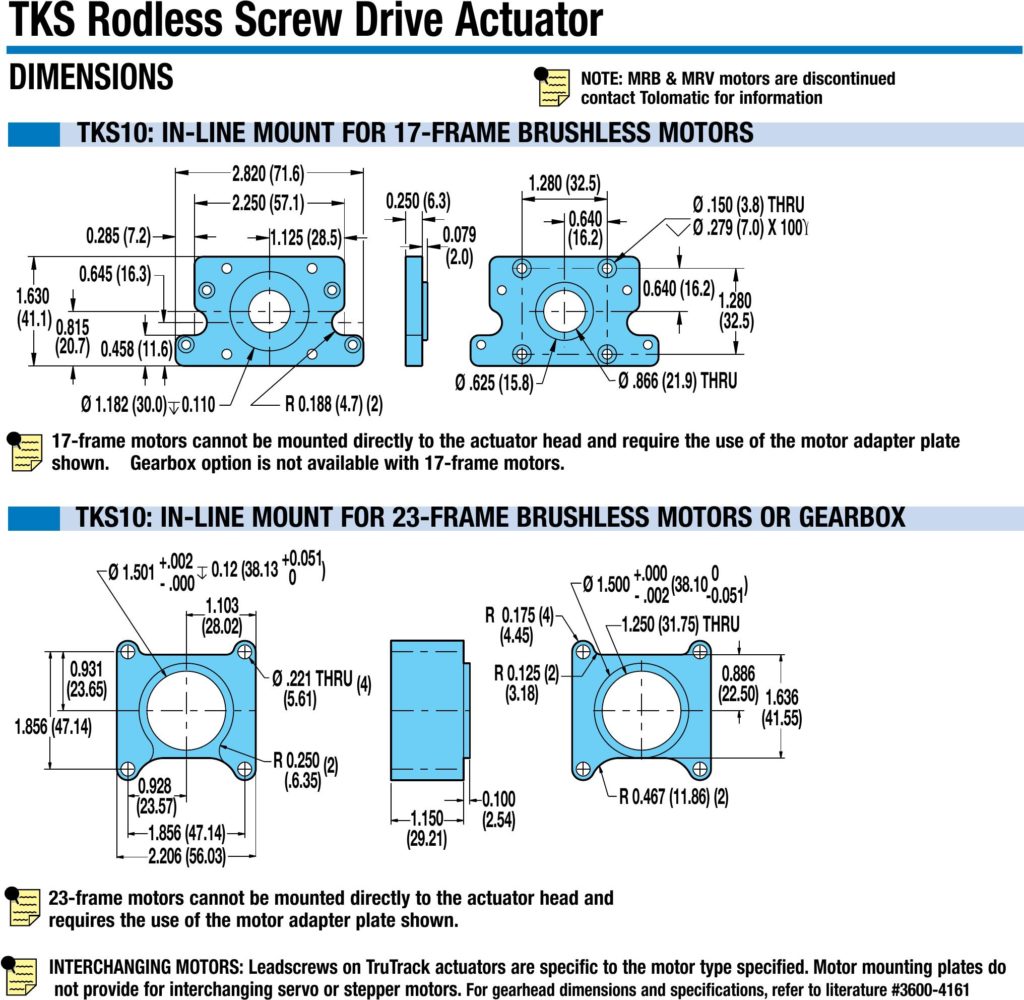

TKS Mount Option Dimensions

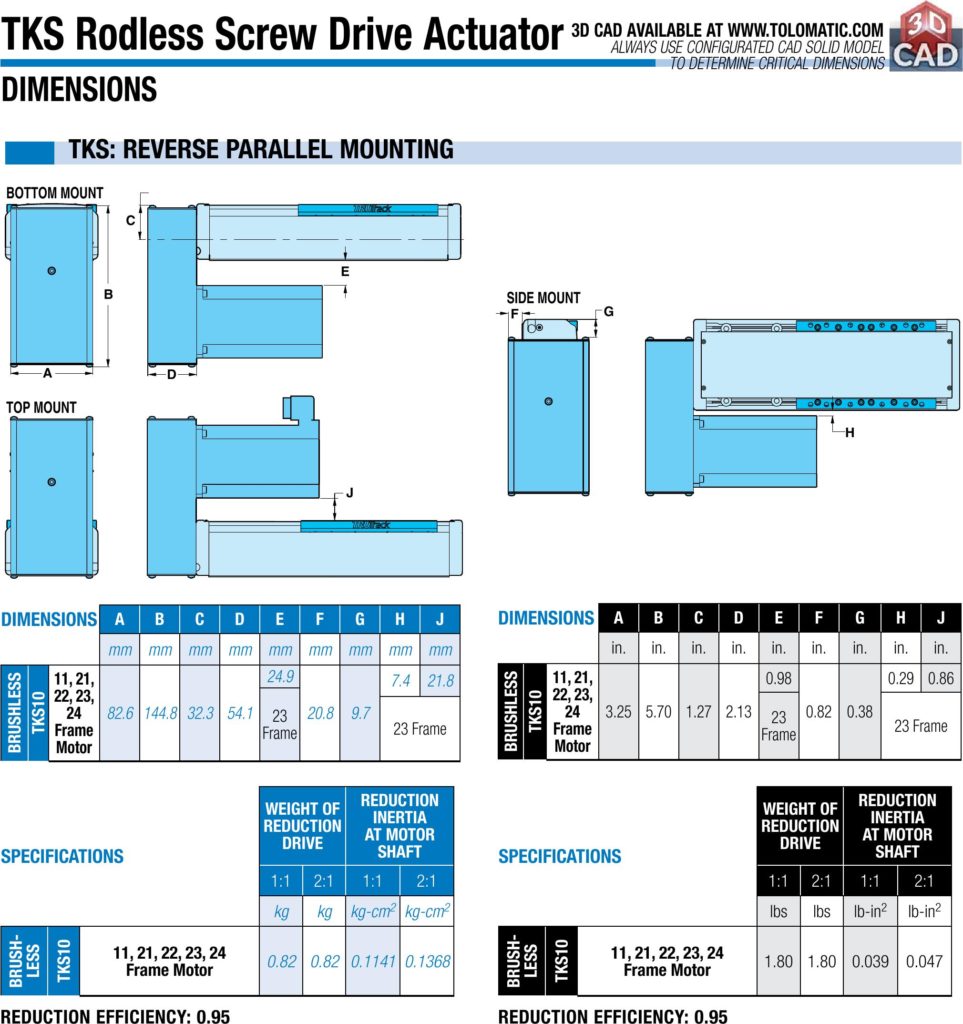

TKS Reverse Parallel Mounting Dimensions

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

English

Chinese

German

Spanish

Application Checklists

Catalogs & Brochures

E-Books

Guides

- Selecting the Optimal Screw Technology

- Actuator Life: How to estimate for ball and roller screw actuators

- INFOGRAPHIC: Accuracy and Repeatability in Linear Actuators

- INFOGRAPHIC: Ten Tips for Specifying Rodless Electric Linear Actuators

- INFOGRAPHIC: Calculating Total Cost of Ownership

- 如何选择 螺杆? 甄选 正确的技术 (Chinese, How to select the right lead screw for an electric actuator)

- Guide to Third Party Motor Integration

Tech Bulletins

Terms & Conditions

White Papers

- Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership

- The truth about actuator life: Screw drive survival

- Select the right linear actuator: Making sense of manufacturer specifications

- Specifying electric rodless actuators: Ten tips for maximizing actuator life and system performance

- Rules of actuator and guide alignment in linear motion systems

- IP ratings and the manufacturing environment: How to apply linear actuators for quality, safety and long service life.

- Minimizing electrical noise in actuator drive systems for maximum reliability and performance

- Screw-driven vs. belt-driven rodless actuators: How to select drive trains for reliability, efficiency and long service life

- Introduction to accuracy and repeatability in linear motion systems

- Elektrische Stangenantriebe vs. Hydraulikzylinder: Ein Vergleich der Vor- und Nachteile beider Technologien weißes Papier (Electric vs Hydraulic WP, German)

- Elektrische Stangenantriebe vs. Hydraulikzylinder: Ein Vergleich der Vor- und Nachteile beider Technologien weißes Papier (GERMAN, Electric vs Hydraulic WP)

Ask an Engineer

Ask an Engineer