Solving Harsh Environment Challenges for Linear Motion

Electric linear actuators deliver excellent performance in extreme environmental challenges like those found in lumber processing, mining and other applications.

Electric Actuators Help You Keep Up With the NFPA Technology Roadmap

A recent National Fluid Power Association (NFPA) survey illuminated technology objectives that enable machine builders and OEMs to stay competitive in their industries. The most important objectives that emerged from the survey included: ● Increased availability and uptime ● Increased productivity and performance ● Regulation compliance ● Lower total cost of ownership

Maximize Your Uptime With Electric Linear Actuators

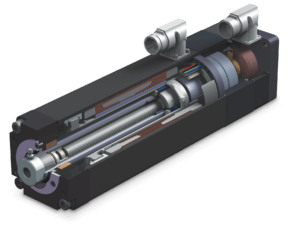

Maximize Your Uptime With Electric Linear Actuators To meet demand to minimize downtime in automation environments, many engineers are turning to electric linear actuators to design low-maintenance machines.

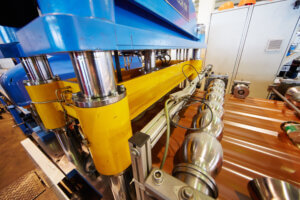

How Electric Actuators Optimize Pressing Applications

It’s common for presses to feature hydraulic or pneumatic cylinders, but using electric actuators can optimize many press designs. Linear servo presses, which rely on electric actuation, eliminate noisy and leaking hydraulic and pneumatic components.

Ask an Engineer

Ask an Engineer