High force linear actuators: How to convert from hydraulics to electric

For high force linear actuator applications, machine designers often first look to hydraulic cylinders. For good reason, too – hydraulic cylinders can be a bargain to purchase, delivering high force at a low cost per unit of force. Plus, they’re rugged and well understood. But there’s another technology to consider. Electric linear actuators are available with high force capacities. These actuators are more flexible, precise and reliable than their hydraulic counterparts.

Electric high speed linear actuator reduces conveyor’s TCO

Higher production speeds usually translate into higher output volumes – a good thing in manufacturing. At least it’s good if product quality stays high and operating costs remain in line. Machine designers are on the look-out for high speed linear actuators and other devices that can streamline processes. But those high-speed solutions need to be reasonably priced and efficient to use.

Test your motion control smarts. Take the electric linear actuator quiz.

Linear actuators are common and critical elements in many industrial machines and automation systems. With so many choices on the market, it’s important to know how to select the best one for your application.

You probably know a lot about linear actuators. But do you know everything? Our electric linear actuator quiz will test your engineering smarts.

Electric rod actuators add accuracy and repeatability to PCB manufacturing

Some manufacturing processes require high precision -- printed circuit boards (PCB) production, for example. In these instances, the capabilities of each component in a production system are critical. Although machine designers know pneumatic cylinders well, these cylinders struggle to deliver the accuracy and repeatability demanded by high precision processes. Many design engineers now turn to electric rod actuators for accuracy and repeatability and for better operating efficiency.

10 tips for specifying electric rod actuators: Part 2

In many applications electric rod actuators are a great solution. Compared to pneumatic or hydraulic cylinders, electric linear actuators offer more control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often the superior actuation choice.

10 tips for specifying electric rod actuators: Part 1

There are lots of good reasons for specifying an electric rod actuator. Electric linear actuators offer a high degree of control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often a superior actuation choice compared to pneumatic or hydraulic cylinders.

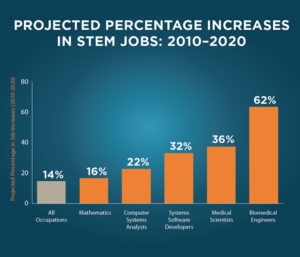

Supporting STEM education

Science, technology, engineering, and mathematics (together known as STEM) impart valuable life skills. STEM subjects teach students how to gather and evaluate evidence, make sense of information, and use new insights and knowledge to find solutions to complex problems.

How to select electric linear actuators that stand the test of time

The length of time a linear actuator will function (i.e., service life) is critically important to a machine designer. Machines need to keep working reliably with little or no need for lengthy maintenance that will take a machine off-line . So, components like actuators must keep working.

Electric high force linear actuator is tough enough to process lumber

The lumber industry has relied on the toughness and high force capabilities of hydraulic cylinders for years. But lately that reliance has been shaken. Hydraulic cylinders leak and can contaminate the fragile eco-systems in which lumber processing operates. Plus, hydraulic systems are only 40-55% efficient and cylinders require frequent maintenance. When combined, these factors can make hydraulic cylinders an expensive choice in the long run.

The introduction of electric high force linear actuators has given the lumber industry a new option for linear motion.

Total cost of ownership: pneumatic vs electric linear actuators

Who doesn’t like to save money? We’re all in search of a good deal, but how do you define what’s good? If you buy something on the cheap but it falls apart in a short time, is that a good deal? Maybe it’s smarter to pay more for something that last longer and performs better.

In business, this means considering total cost of ownership (TCO), that is, initial acquisition cost plus operating costs. Comparing TCO to purchase price alone is especially interesting when applied to pneumatic and electric linear actuators.

Ask an Engineer

Ask an Engineer