Five tips for designing electric actuators into food processing equipment

Machines used for food processing increasingly must be designed to meet ever-stringent requirements to keep food clean during production and ensure it arrives safely to the consumer. Hygienic actuators are a key ingredient to help maintain the highest standards for health and safety.

Design it yourself: 4 steps to actuator selection

Size and select your actuator with easy online tools.

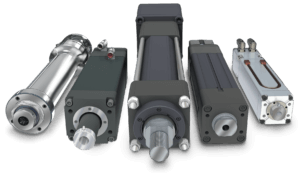

Small yet beefy

An internal servo motor makes for a smart, heavy duty and compact electric actuator package, one that is easy to retrofit or install new.

A pressing need

An electric servo-mechanical press offers all the versatility of a hydraulic press, with production speeds close to a flywheel press.

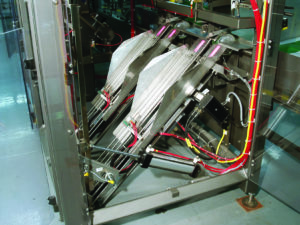

In the bag

Rodless electro-mechanical actuators on a modular bagging system precisely position incoming bags regardless of size.

Gantry and multi-axis system: Build it your way

Gantries can be complicated and specialized. There are infinite variations for moving an object on multiple axes. But multi-axis motion control systems don’t have to be intimidating if you follow a straight-forward method that involves four steps.

Extend your reach

Actuators create the motion for collaborative robots and autonomous guided vehicles, whether it’s extending the reach of a robotic arm or steering a 40-foot shipping container.

Ask an Engineer

Ask an Engineer