Selecting a rodless electromechanical actuator: belt- vs. screw-driven

By Igor Glikin on July 12, 2016

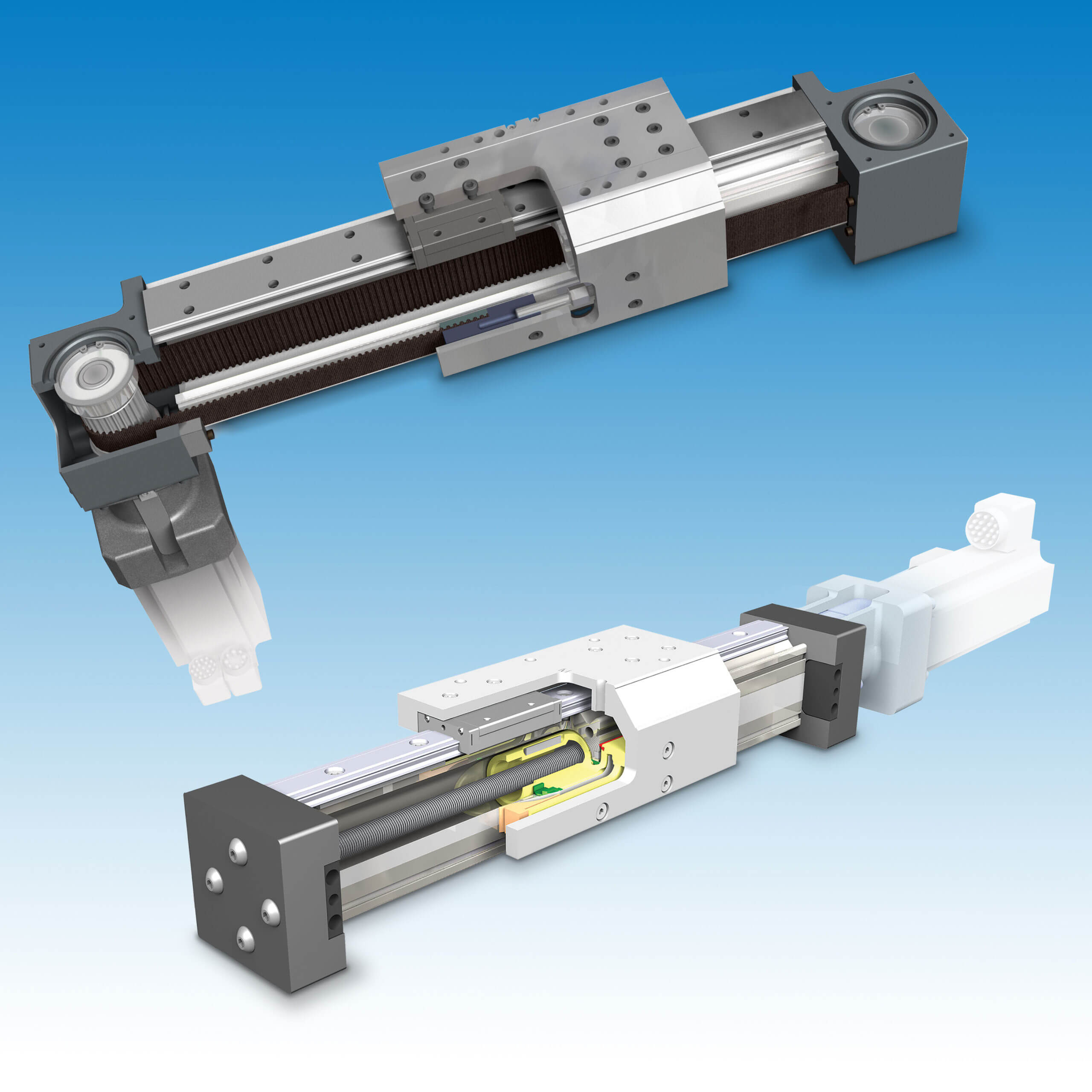

Let’s say you’ve decided you need a rodless electromechanical actuator to carry a load in your application. Now you have to select a linear drive system. The two most common choices are screw drives and belt drives. Both drive types offer long life, low maintenance, and efficiency in converting the motor’s rotary motion to the carrier’s linear motion. However, each drive type is more suited to particular applications than others, depending on a few key factors.

Let’s say you’ve decided you need a rodless electromechanical actuator to carry a load in your application. Now you have to select a linear drive system. The two most common choices are screw drives and belt drives. Both drive types offer long life, low maintenance, and efficiency in converting the motor’s rotary motion to the carrier’s linear motion. However, each drive type is more suited to particular applications than others, depending on a few key factors.

This blog will review the advantages and disadvantages of these linear drive systems. For a detailed explanation, download our white paper.

The key factors you’ll need to consider in your drive train choice are:

- accuracy/repeatability

- length of stroke

- velocity

- orientation of the move

Let’s take a closer look at each of them.

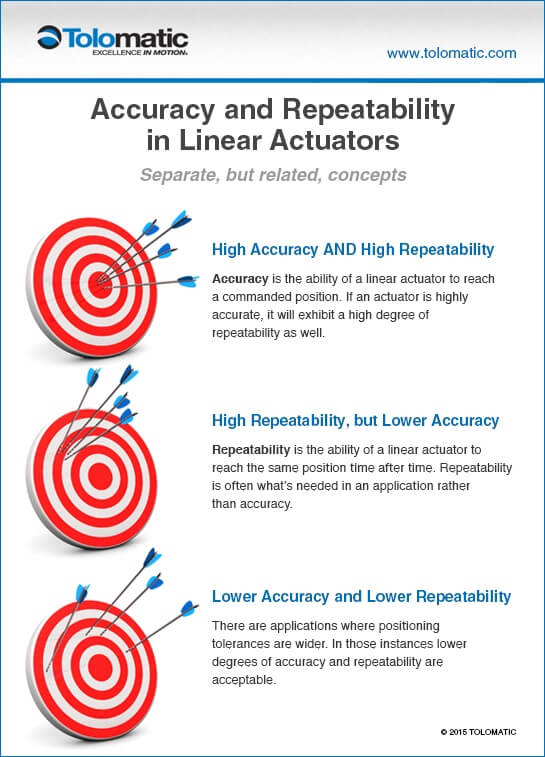

Accuracy/repeatability

Accuracy is the ability of an actuator to achieve a specified position. Repeatability is the ability of an actuator to achieve a position time after time. Each application will have its own requirements for accuracy and repeatability.

A screw-driven linear actuator’s accuracy/repeatability performance depends on the screw type and the method in which the screw and nut were manufactured. For example, actuators with precision-rolled ball screws can combine very good accuracy and repeatability with an affordable price. Acme (lead) screws often offer a lower level of accuracy at a lower cost while roller screws (uncommon in rodless electromechanical actuators) offer the highest accuracy with an accompanying high price

A belt-driven linear actuator will deliver lower levels of accuracy due to the variations in the belt material.

Length of stroke

The length of the stroke of a screw-driven linear actuator is often limited by the available length of the screw stock. Screw-driven actuators are most often used in stroke lengths of less than 120 inches.

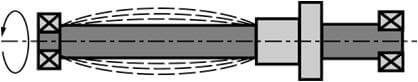

Screw length and  speed are related. Critical speed (see below) decreases as screw length increases.

speed are related. Critical speed (see below) decreases as screw length increases.

Belt drives, on the other hand, can reach very long lengths without affecting speed. In fact, the length of a belt drive is limited only by the ability to tension long belts. Belt-driven linear actuators can achieve stroke lengths of over 200 inches (5080 millimeters).

Velocity

The speed at which a screw-driven linear actuator travels is limited by the critical speed value of the screw. The critical speed is a rotational speed  that approaches the system’s natural frequency, leading to resonance and vibration (also known as “screw whip”). Screw whip can lead to actuator malfunction and catastrophic failures. Screw-driven linear actuators typically operate at no more than 60 inches per second (about 1500 mm/second).

that approaches the system’s natural frequency, leading to resonance and vibration (also known as “screw whip”). Screw whip can lead to actuator malfunction and catastrophic failures. Screw-driven linear actuators typically operate at no more than 60 inches per second (about 1500 mm/second).

Belt-driven linear actuators are not limited in this way and can achieve speeds of 200 inches/second (5080 mm/second).

Orientation

There are several ways a linear actuator can be mounted depending on the orientation of the required move:

- horizontal

- side

- incline

- vertical

Of these, vertical orientation and some incline orientations can present problems resulting from back driving (the tendency of an actuator carrier plus load to free fall due to gravity). Actuators with acme screws of certain leads are resistant to back driving because of a higher coefficient of friction between the nut and screw threads, but a ball screw actuator will require a brake to prevent back driving in the event of a power loss.

Of these, vertical orientation and some incline orientations can present problems resulting from back driving (the tendency of an actuator carrier plus load to free fall due to gravity). Actuators with acme screws of certain leads are resistant to back driving because of a higher coefficient of friction between the nut and screw threads, but a ball screw actuator will require a brake to prevent back driving in the event of a power loss.

Belt-driven linear actuators are susceptible to back driving as well and must have emergency brakes for the same reasons.

In summary

Some applications make it easy to choose a linear drive system. Belt-driven linear actuators are ideal for long-stroke applications requiring high velocity and acceleration. If the application’s stroke length and speed requirements are moderate but the accuracy level required is high, then a screw-driven actuator is best.

When the choice isn’t obvious, see our white paper for helpful information: Screw-driven vs. belt-driven rodless actuators: How to select drive trains for reliability, efficiency and long service life. Download it here.

Ask an Engineer

Ask an Engineer