Long Lasting, High Precision, Low Maintenance

Selecting the Optimal Screw Technology

When you work with Tolomatic for roller screw linear actuators — with electric, high force, heavy duty, ball screw, hygienic and other options available — you’re guaranteed help selecting the optimal screw technology for your specific application. We don’t take a “one technology” approach to customer needs — we help provide industry-best sizing, selection, quality and application advice backed by reliable aftermarket service.

Read Now

Discover the Features and Advantages of Roller Screws

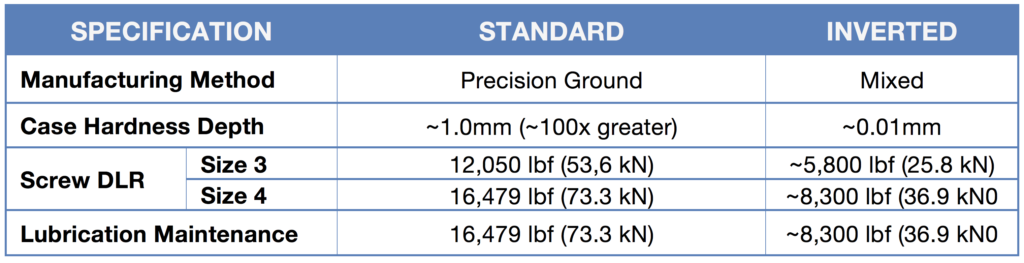

Standard Planetary Roller Screw vs. Inverted Roller Screw

This chart reflects integrated servo actuators with standard and inverted screw designs. The DLRs listed here are selected from like-sized product.

By utilizing the inverted design in an actuator, the actuator may be a little more compact than an actuator with a standard roller screw, but this comes at a sacrifice of lower DLR (lower life).

Because of this, Tolomatic only supplies linear actuators with standard planetary roller screws to maximize service life.

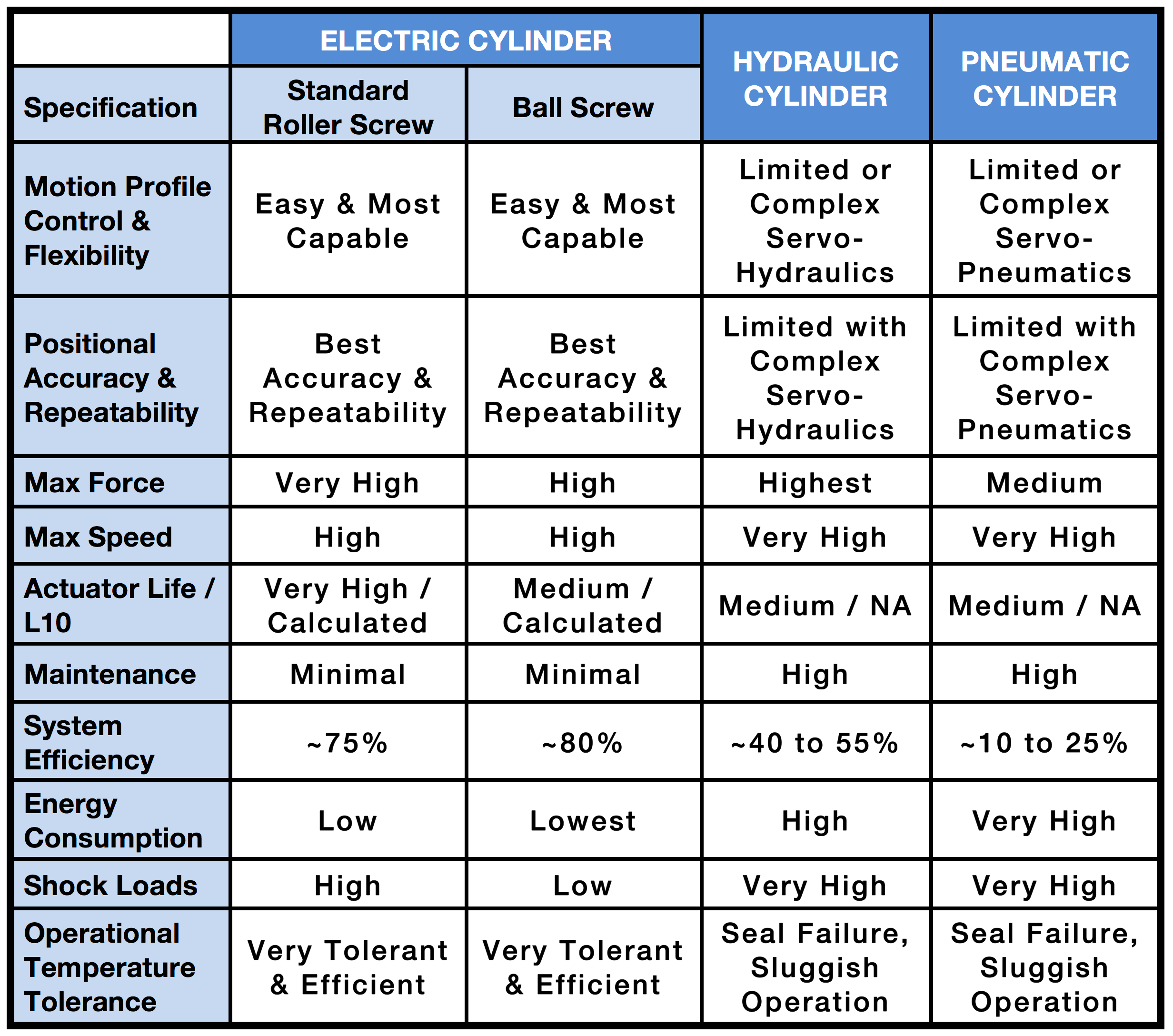

How do you select the correct screw for heavy duty, high force linear actuator applications?

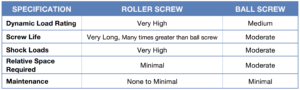

There are several screw technology options to consider when specifying high force electric linear actuators – standard planetary roller screws, inverted roller screws and ball screws. Each technology has its advantages and disadvantages when compared to one another.

To select the best option, it is critical to let the application specifications be the guide. Some companies only sell ball screw linear actuators — electric, heavy duty or otherwise — and some companies only sell roller screw linear actuators. Take caution when evaluating “there is only one technology” type vendors. Every application is different and both technologies have their unique strengths.

Tolomatic manufactures both roller screw and ball screw high force electric linear actuators. Tolomatic’s online electric actuator sizing software guides engineers through application specifications including force, speed, dwells, life estimates and other factors in order to make the correct choice.

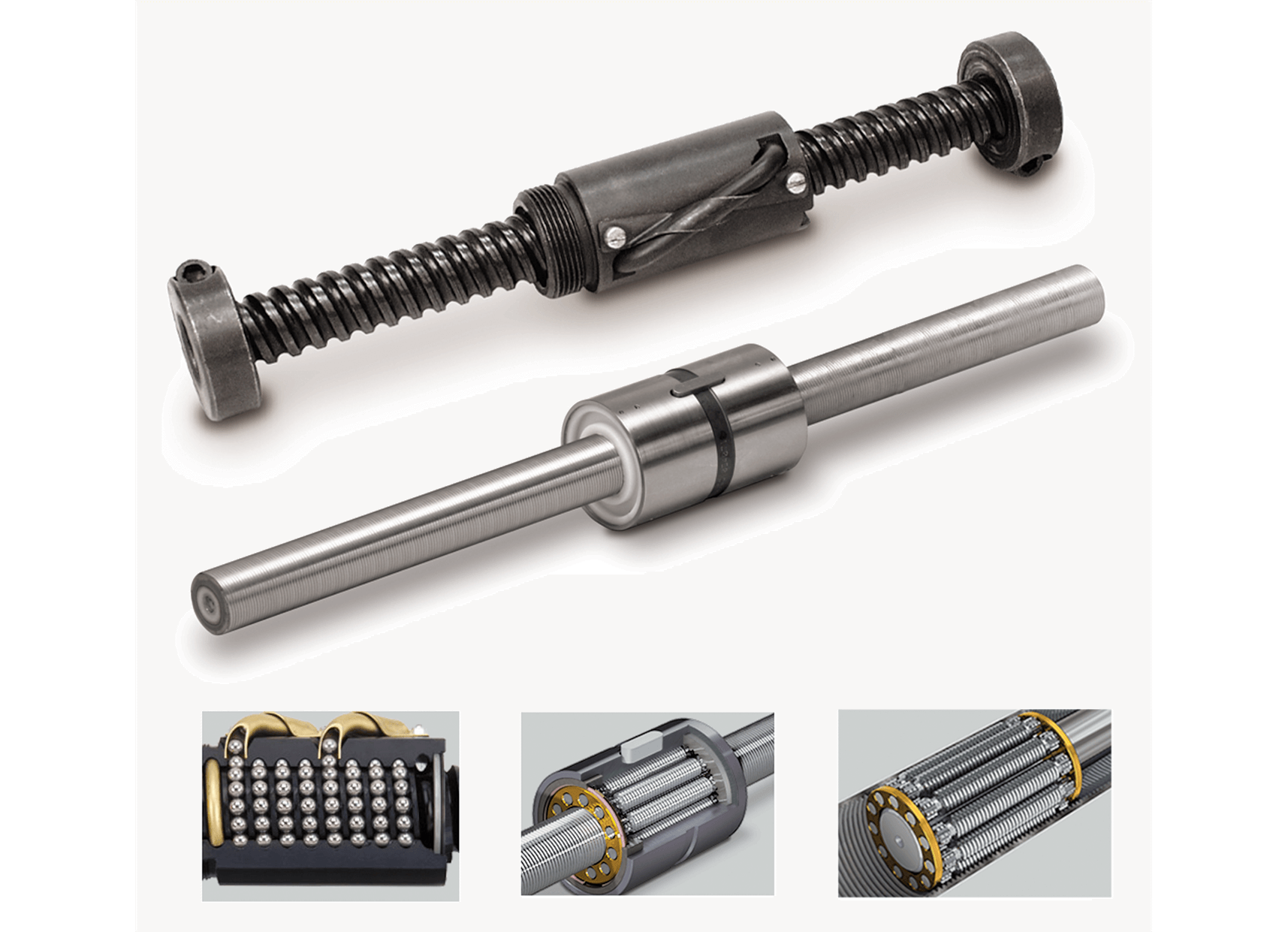

What’s the difference between ball and roller screws (inverted and planetary)?

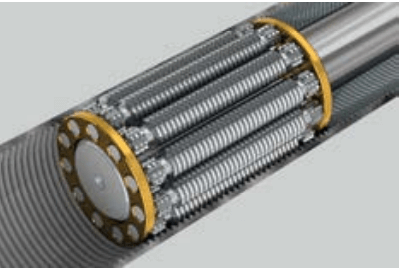

Standard Planetary roller screws offer the highest dynamic load rating for the longest life of the three technologies. Additionally:

- Both roller screw technologies are good choices for repeated stress applications (pressing, inserting, riveting) in the same area of actuator stroke.

- Roller screws have a significant increase in contact area which allows for longer life and higher forces exerted in the same package size compared to ball screws. However, this increased contact area also creates more heat with the same amount of work.

- Ball screws, because they have less contact points, are a little more efficient in heat management than roller screws which allows them to operate cooler in high duty cycle and high speed applications.

- Heat management is a major factor in how well lubricants hold up over time and whether the actuator or screw can last as long as expected.

How do inverted roller screw linear actuators work?

An inverted roller screw operates much the same as a standard roller screw except the functions of the nut and screw are reversed so the rollers move inside the nut.

Most inverted roller screws used in linear actuators are produced using a process other than grinding to inexpensively create threads inside the nut. The hardening process is performed after the nut is machined and results in a much shallower case hardness depth and softer threads than those of standard roller screws. This leads to a significantly lower DLR* (lower life) and more challenges with maintaining lubrication.

How do ball screw linear actuators work?

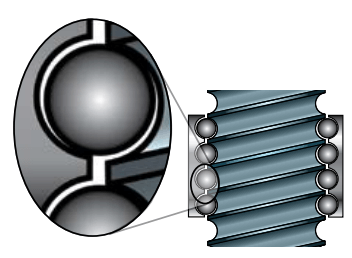

Ball screws get their name from the recirculating ball bearings that fit between arch-shaped screw threads and corresponding threads in the nut. The ball bearings transmit force and relative motion efficiently as they roll through one or more circuits in the nut.

Electric ball screw linear actuators have higher heavy duty thrust capabilities, longer service lives and higher efficiency than those with acme screw systems, but they can’t match the performance of roller screw actuators.

Ball screw actuators can be back-driven and noisy. They’re ideal for applications that require high duty cycles, moderately high thrust and moderate speeds and tend to be reasonably priced, making them popular in many applications. When it comes to comparing roller screw vs ball screw of similar size and lead, a ball screw’s ball bearings have fewer points of contact than roller screws as shown in the diagram below.

For most applications that require high force, repetitive cycles and long expected life, Tolomatic will recommend a roller screw linear actuator. However, if the force is lower and high continuous speeds are present in the application, Tolomatic may recommend a ball screw actuator.

Take a Closer Look at Tolomatic Roller Screw Linear Actuators

Precision ground planetary roller screws provide higher force capability, efficient operation, and longer machine life.

Hydraulic-class electric linear actuators that are roller screw driven, and provide extremely high forces, precision, and long life. Ideal for hydraulic replacement. Forces up to 66,000 lbf (294 kN).

Integrated servo motor and rod style spot welding actuators offer a cost-effective design with solid performance. Forces up to 4,950lbf (22.0kN).

Electric rod actuator integrated with a servo motor in a single, compact design that integrates with 3rd party drives and accessories. Forces up to 8,044 lbf (35.8 kN).

Ask an Engineer

Ask an Engineer