ServoChoke® SVC Electric Choke Valve Actuator / Operator

ServoChoke® SVC is a high performance linear integrated electric choke valve actuator that meets the rigorous needs of the oil and gas industry.

The SVC provides a reliable, high-speed, precision electric choke operator for performance drilling applications. The ServoChoke SVC is perfect for Managed Pressure Drilling (MPD), Set-point choke control and Choke & Kill for well control applications. ServoChoke electric choke valve actuators include an integrated servo motor, gear box and planetary roller screw to enable quick and continuous modulation with highest accuracy.

- Globally certified: CID1 — ATEX — IECEx

- Speeds up to 19.6 mm/sec (0.77″/sec) – open/close choke in less than 3.2 seconds

- Rugged NACE MR0175 compliant steel body

- Planetary roller screw for long life and no maintenance

- Positional repeatability to within 0.08% of span or better

- Temperature range: -40° to +60°C (-40° to +140° F)

Features & Ordering

ServoChoke Electric Choke Valve Actuator

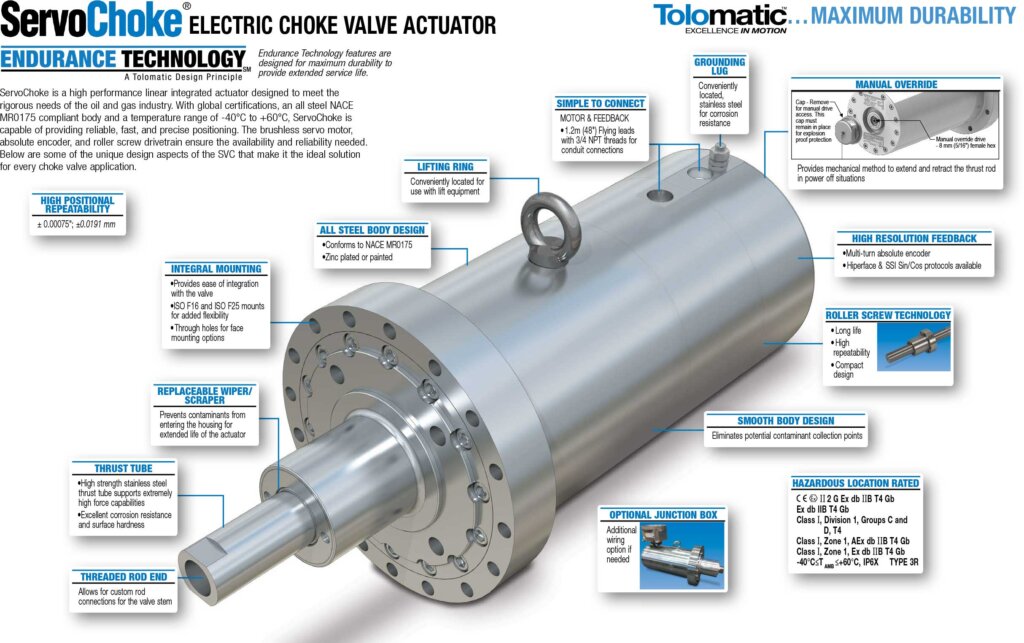

ServoChoke is a high performance linear integrated actuator designed to meet the rigorous needs of the oil and gas industry. With global certifications, an all-steel NACE MR0175 compliant body and a temperature range of -40°C to +60°C, ServoChoke is capable of providing reliable, fast, and precise positioning. The brushless servo motor, absolute encoder, and roller screw drivetrain ensure the durability and reliability needed for a wide variety of environments.

Review this graphic for a closer look at some of the unique design aspects that make the SVC the ideal actuator for choke valve applications.

ServoChoke Features

ServoChoke Features & Options

ServoChoke Electric Choke Valve Actuator and Drive System

Safe, reliable operation of both the electric valve choke actuator and drive system.

- Pre-configured motor and feedback device

- Pre-tuned for a variety of forces/pressures and temperature ranges

- Current limits (Peak & RMS) preset to prevent actuator damage

- System tested to verify proper operation

- Integrates with any PLC or control system

- Successful integration with servo drives from Siemens, Parker, ABB, Kollmorgen, Rockwell Automation and Nidec

ServoChoke Testing and Simulation

Tolomatic’s hydraulic simulator test stand allows ServoChoke to be tested to any conditions.

- Thermal chamber for -40 to +70°C ambient temperature testing

- Adjustable stem loading monitored by a load cell rated for 445 kN (100,000 lbf)

- Infinite modulating conditions for travel distance, and time between moves

- Use of motor feedback, servo drive, scope trace programs, and additional instrumentation monitors all performance aspects such as position, accuracy, repeatability, and velocity

ServoChoke Field Testing With Real World Results

- ServoChoke has been successfully deployed on real-world MPD jobs with highly favorable results

- In North America alone ServoChoke was field deployed at temperatures as low as -40°C (-40°F) and over 32°C (86°F) within the first year with no winterizing or thermal protection equipment used

- Not only in the lab but in the field, ServoChoke is proving to be a rugged, precise, and dependable part of an entire MPD service package

Why Electric Actuators Are Superior to Hydraulic Systems for Control of Choke Valves

MOTION CONTROL

HYDRAULIC CHALLENGE

Fluctuating speeds and positions sometimes require frequent valve adjustments. This adds to down time and can require expensive complex peripheral equipment to correct.

ServoChoke SOLUTION

Motion control systems are designed to self-compensate — position, speed, acceleration (deceleration) and force are precisely controlled and fully programmable.

HYDRAULIC CHALLENGE

Complex and/or long set-up of hydraulic systems to connect hoses, wire and set-up peripheral sensors or equipment. Filling and purging these systems is time consuming and requires continual monitoring to prevent failure.

ServoChoke SOLUTION

Simple setup with only one power cable and one feedback cable. No maintenance required — lubricated for life, no fluids or filters to change.

HYDRAULIC CHALLENGE

In order to maintain peak precision, periodic adjustment of the backlash between the gear and screw is necessary. Lubrication of these two components is also required by the manufacturers.

ServoChoke SOLUTION

High precision automation grade components do not require mechanical adjustment to maintain peak repeatability. Performance will remain consistent from initial deployment to the end of its useful service life.

Why Electric Systems Are Superior to Hybrid Systems for Control of Choke Valves

Life

HYDRAULIC CHALLENGE

Jack screws are designed for duty cycles of approximately 40% or less. Exceeding this duty cycle will increase the rate of wear between the drive gear and screw thus increasing the backlash.

ServoChoke SOLUTION

All ServoChoke components are designed and intended for continuous duty operation. Service life of the unit can be predicted using industry standard B10/L10 calculations as hardened-steel power transmission components are used.

Maintenance

HYDRAULIC CHALLENGE

In order to maintain peak precision, periodic adjustment of the backlash between the gear and screw is necessary. Lubrication of these two components is also required by the manufacturers.

ServoChoke SOLUTION

ServoChoke’s high-precision, automation-grade components do not require mechanical adjustment to maintain peak repeatability. Performance will remain consistent from initial deployment to end of service life.

Obsolescence

HYDRAULIC CHALLENGE

Multiple components must be individually sourced and assembled together. These parts are from multiple vendors and carry individual certifications where applicable. Component obsolescence can impact assembly availability and require additional testing and validation of new components to ensure equivalent performance.

ServoChoke SOLUTION

The entire ServoChoke assembly is certified allowing standard components to be designed in and sourced from a single supplier to eliminate disruptions in the supply chain and ensure consistent performance.

Speed

HYDRAULIC CHALLENGE

To achieve force and life requirements, high gear reductions and increased mechanical inefficiencies are required which can limit the linear velocity of the gate and allow the unit to be self locking for choke operations.

ServoChoke SOLUTION

ServoChoke’s high-efficiency design reduces the amount of mechanical reduction. This allows full utilization of a servo motor’s RPM range resulting in a 20-80% increase in speed and utilizes an industry standard failsafe brake to reliably hold the choke actuator in place during power loss conditions.

Precision

HYDRAULIC CHALLENGE

Minimum backlash in a jackscrew assembly is normally 0.051mm (0.002″). This value will increase with time and wear.

ServoChoke SOLUTION

ServoChoke replaces the conventional jack screw with a precision-hardened planetary roller screw, reducing backlash to less than 0.025mm (0.001″). This precision is maintained throughout the usable service life of the choke actuator and life can be predicted using industry standard L10 life calculations.

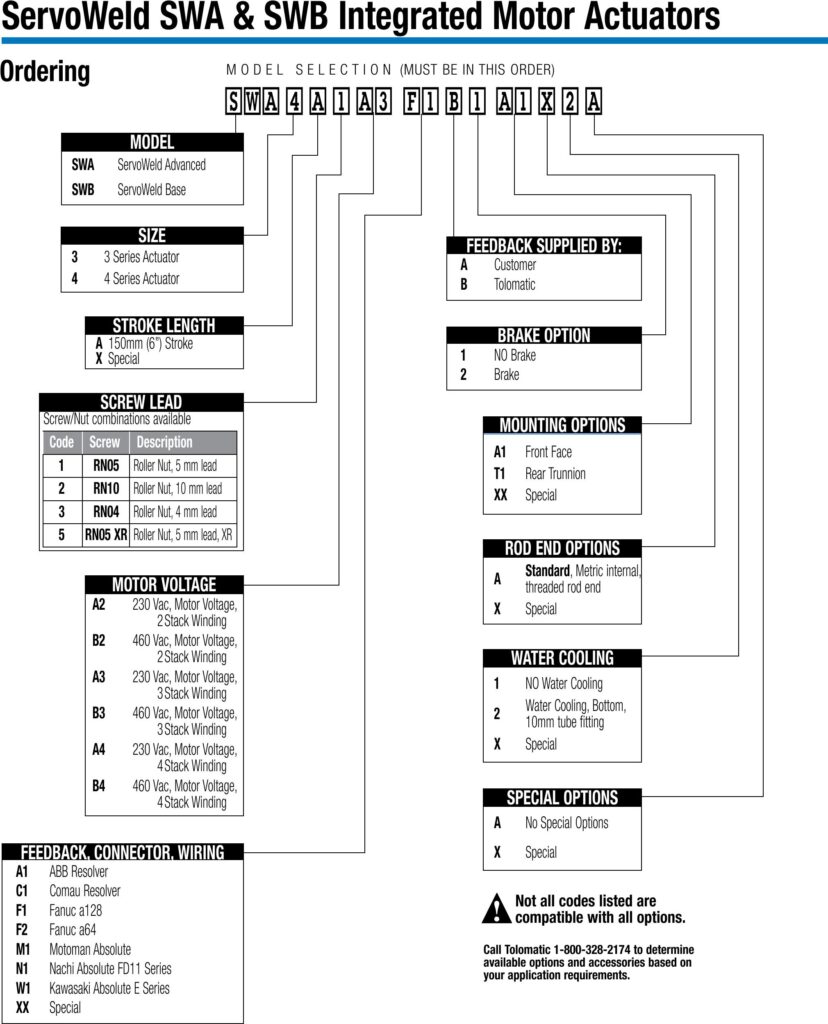

ServoWeld® SWA/SWB Ordering

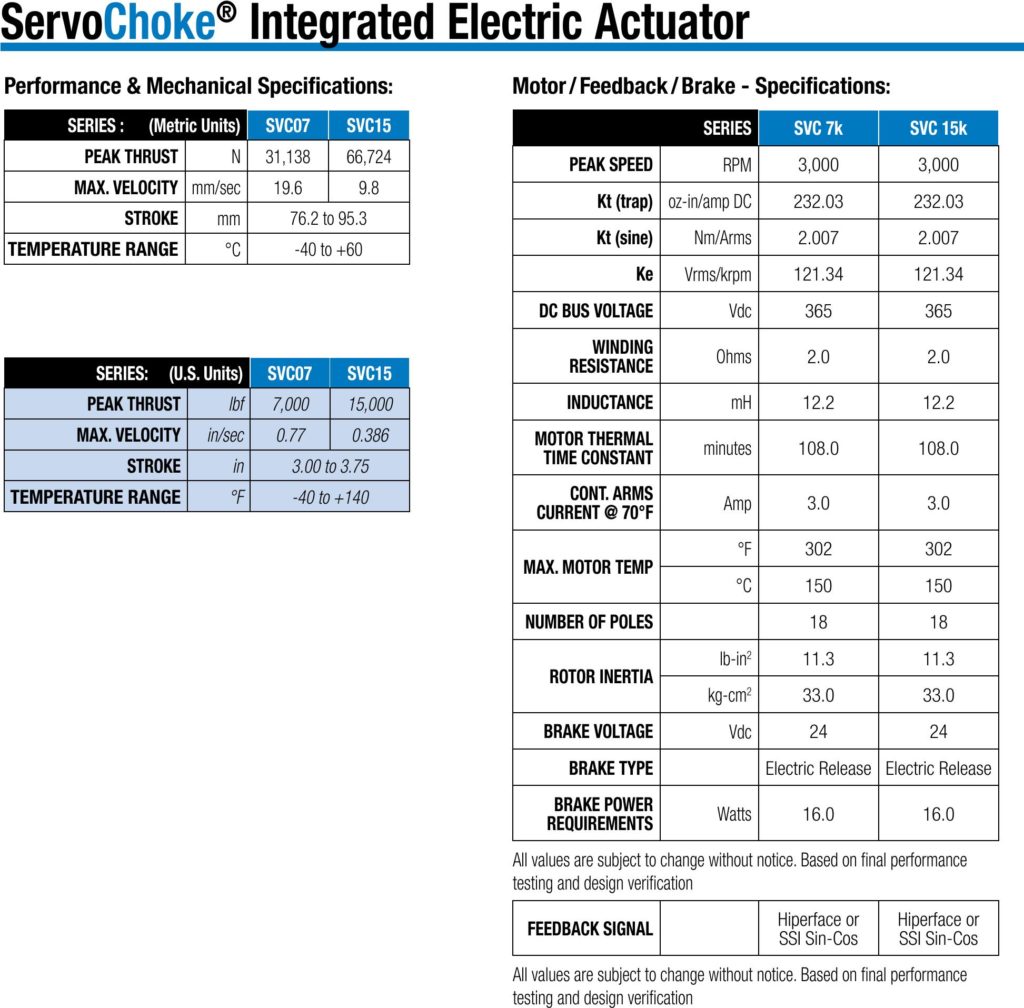

Specifications

Performance & Specifications

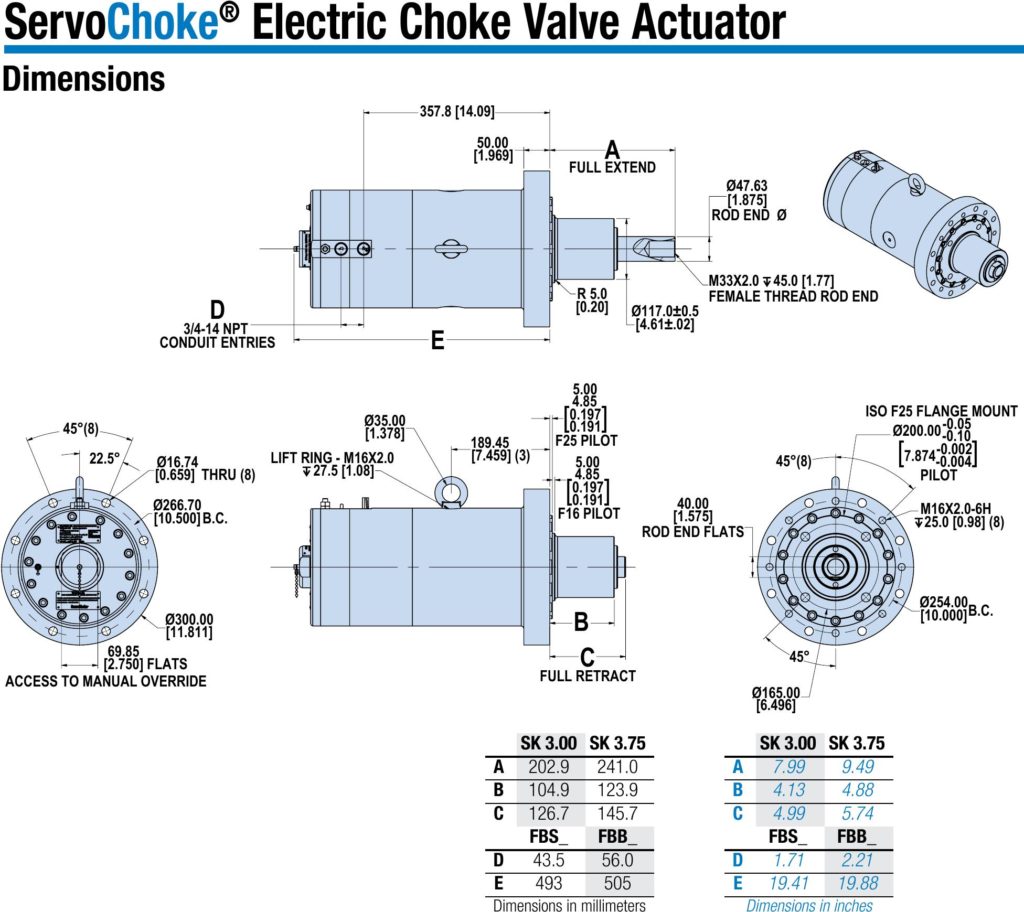

Dimensions

ServoChoke Dimensions

Manuals & Part Sheets

Additional Resources

Information Center:

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- 公司概述 (Chinese, Corporate Overview Brochure)

- Brochure sur l'entreprise Tolomatic (French, Corporate Overview-Linear Motion Solutions Brochure)

- ServoChoke® Integrated Electric Actuator

- ServoChoke®集成电动推杆-中文 (ServoChoke® Integrated Electric Actuator-Chinese)

- OEM Actuator Solutions Brochure

Certifications

- ISO 9001 Certificate - Facility: Hamel, MN

- ServoChoke Certificate: Class I, Division 1, Groups C & D; Tcode: T4

- ServoChoke Certificate: INTERNATIONAL ELECTROTECHNICAL COMMISSION IEC Certification Scheme for Explosive Atmospheres

- ServoChoke Certificate: EU-Type Examination

- ServoChoke SVC 7K & SVC 15k EU Declaration of Conformity

- Umfang und Umweltpolitik des Tolomatic Umweltmanagementsystems (UMS)

- Tolomatic Scope and Environmental Policy

Software & Firmware

Tech Bulletins

Terms & Conditions

Success Stories

Additional ServoChoke information

ServoChoke® SVC is a high performance linear integrated electric choke valve actuator that meets the rigorous needs of the oil and gas industry. The SVC provides a more reliable, high-speed, precision electric choke operator in performance drilling applications vs. conventional hydraulics or jack screw assemblies. The ServoChoke SVC is perfect for Managed Pressure Drilling (MPD), Set-point choke control and Choke & Kill for well control applications.

ServoChoke electric choke valve actuators include an integrated servo motor, gear box and planetary roller screw to enable quick and continuous modulation with highest accuracy. With global certifications for ATEX, IECEx, and Class I Div. 1 together with a temperature rating of -40° C to +60° C, the all steel SVC choke actuator is designed to perform in the harshest environments.

- Globally certified: CID1 • ATEX • IECEx

- Worry-free performance in the most hazardous location environments

- Speeds up to 19.6 mm/sec (0.77″/sec) – open/close choke in less than 3.2 seconds

- 3 mm (0.125″) adjustments happen in less than 0.5 second

- Temperature range: -40° to +60°C (-40° to +140° F)

- Positional repeatability to within 0.08% of span or better

- Planetary roller screw for long life and no maintenance

- Fully integrated motor/actuator/feedback in a single, sealed housing

- Rugged NACE MR0175 compliant steel body

Contact Tolomatic to learn more about how our high performance electric choke valve actuators can meet the particular needs of your unique drilling application.

View the video interview at the IADC Managed Pressure Drilling & Underbalance Conference

Ask an Engineer

Ask an Engineer