This section is for frequently asked questions regarding Tolomatic’s pneumatic motion control products. If you have a question not covered here, feel free to reach us at 1-800-328-2174 or help@tolomatic.com

BC2 cylinders maximum stroke range from 13.6 feet (4.1 m) to 29 feet (8.8 m), depending on the bore size. For exact maximum stroke lengths on any pneumatic cylinders please consult the Tolomatic pneumatic products catalog.

First, determine the application requirements and capabilities (stroke length, loads, speeds, available air pressure, etc.). Then choose which series of cylinder (MXP, BC2, BC3, etc.) will fit best for your application based up on these specification. Once you’ve chosen the series use the selection guidelines within the catalog for that series to determine appropriate bore size, and additional options.

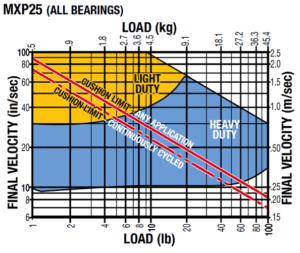

Example selection guideline from MXP catalog:

Pneumatic rodless cylinders: The 10 most common sizing mistakes and how to avoid them: https://dev.tolomatic.com/info-center/resource-details/pneumatic-rodless-actuators-10-most-common-sizing-mistakes/

When sizing a pneumatic cylinder it is important to gather application information on required stroke length, cylinder orientation, available air pressure, required thrust force, mass of load, bending moments from load, maximum travel velocity, and operation environment conditions. Below is a sizing checklist that list out the information needed to size a pneumatic cylinder.

Pneumatic Cylinder Application Checklist: https://dev.tolomatic.com/info-center/resource-details/pneumatic-actuator-application-checklist/

No, pneumatic cylinder orientation will not affect the capability of the carrier. Load, side load, and moment capabilities are the same regardless of orientation.

Yes. Our patented band retention system creates a tight metal to metal seal with the internal diameter of the cylinder bore. And an outer Dust Band keeps dust and grit away from the sealing band. However, it is good to note that no Band Cylinder system can be completely sealed from environmental contamination.

Where can I find repair sheets and kits and info for pneumatic cylinders? Yes. The BC2 is generally field repairable. Below are links to repair kits and repair videos for this actuator.

Pneumatic Products Repair Kits: https://dev.tolomatic.com/info-center/resource-details/pneumatic-products-repair-kits/

BC2 repair videos: https://dev.tolomatic.com/Info-Center/Videos

Yes, dimensionally the BC2 cylinders fit in the same fits in the same envelope as the legacy BC1. The repair parts, however, are not Interchangeable.

While the bore sizes and lengths may be similar, the overall envelope often differs from manufacturer to manufacturer so typically cylinders are not “bolt in” or “drop in” replacements. Some mounting may need to change.

There are multiple limit switch types available for the electric actuators resulting in varying functionality. They all are triggered by a magnet moving with the actuator. To troubleshoot limit switch operation, a few initial troubleshooting steps should be followed:

The 100-cable cylinder series was replaced with the CC series, and resulting in the obsolescence of the 100- series cylinder. The CC series features an upgraded gland seal assembly. The CC series is interchangeable with the 100- series cable cylinders.

Yes, extra cable can be ordered for the cylinder by adding a XA or XB to the end of the configuration string followed the desired length in inches. XA refers to the amount of extra cable on side 1, and XB for side 2.

Example: if a CC20 SK20 with a 2” auto tensioner (HK) and 10 inches of extra cable on the same side as the auto tensioner is required, the configuration string would be as follows.

CC20 SK20.000 HK– XA10.000

To determine if an application requires a shock absorber, the shock absorber graphs in Tolomatic’s pneumatic cylinder catalogs should be consulted. If your load and final velocity combination is above the cushion line then a shock absorber will be required to avoid damage to the cushion. To determine whether a light duty or heavy duty shock absorber is required consult the shaded region in the graph. For more information on shock absorbers and cushions use the following link to read our Application Tip about this topic.

Actuator internal cushions vs. external shock absorbers: Knowing when and how to use them is crucial for maximum actuator life: https://dev.tolomatic.com/info-center/resource-details/actuator-internal-cushions-vs-external-shock-absorbers-knowing-when-and-how-to-use-them-is-crucial/

Automatic tensioners (AT) are required when a cylinder’s stroke length is beyond the maximum stroke length for full manual cable adjustment for that bore size. The AT unit keeps the cable rigid and ensures maximum service life of both the cable and gland seals. AT units are also recommended for vertical lifting or severe, high-cyclic applications. For a list of maximum stroke lengths for cylinders consult the CC Cable Cylinder catalog.

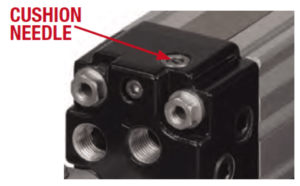

To adjust the landing speed on a pneumatic cylinder, you will need to adjust the cushion needle. Unscrew the cushion needle for a quicker landing speed, and tighten it for a slower landing speed. Only make small adjustments to the cushion needle (less than one full turn) when tuning the cushion.