Innovative mask workcell designed for high-volume mask making

Challenge:

Rapidly create and distribute personal protec-tive equipment in response to the pandemic.

Solution:

B3W electric rodless actuators and GSA electric rod actuators were used on the automated workcell concept to improve efficiency, quality and throughput.

Results:

A nimble machine with high-capacity throughput on a small footprint for a much lower cost of ownership compared to older, larger machines.

Fast throughput on a small footprint:Innovative mask workcell designed for high-volume mask making

NEW YORK CITY—The pandemic hit New York City hardest in April 2020. Charles Boyce, president of Boyce Technologies, Inc. (BTI), New York, heard the grim news reports day after day. His company makes life safety, security and communications equipment for the city’s mass transit system, among other industries. As news unfolded and it became clear there was an immediate need for personal protective equipment (PPE), Boyce knew BTI was uniquely positioned to help. Founded as an advanced rapid development center for electronic and mechanical solutions, BTI specializes in going from concept to product in the blink of an eye by manufacturing standards.

Emergency ventilators were in short supply across New York City and the state. To address that immediate need, BTI joined the Emergency Ventilator Response Team, a consortium formed to rapidly create and distribute solutions in response to the pandemic. The group designed and produced Spiro Wave, a low-cost, easy-to-produce and FDA-approved emergency, or bridge, ventilator, in five weeks. BTI retooled its factory and made thousands of the ventilators for use in New York City and New York State. But the pandemic didn’t stop and neither did BTI.

Partnering with U.S.-based manufacturers

When masks became a mandate and it was apparent there weren’t enough being made—or they were being sold for exorbitant prices—BTI took the same approach as with ventilators: respond quickly, think creatively, design innovatively. These qualities were their biggest strengths in support of their city ravaged by the pandemic.

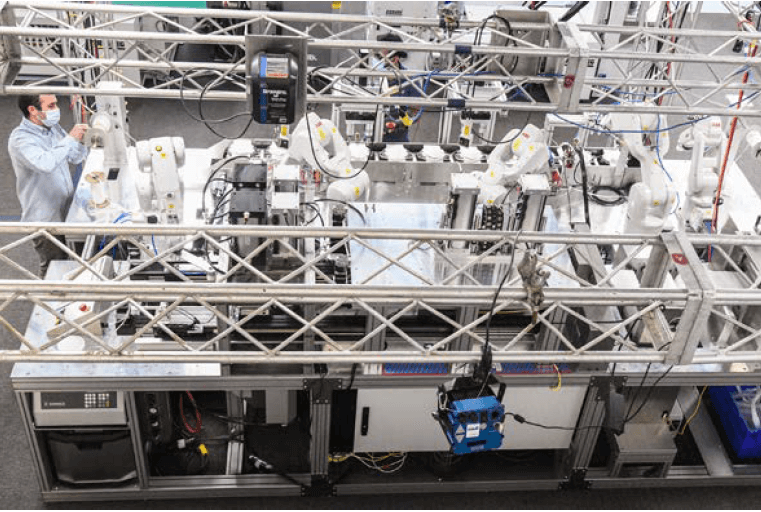

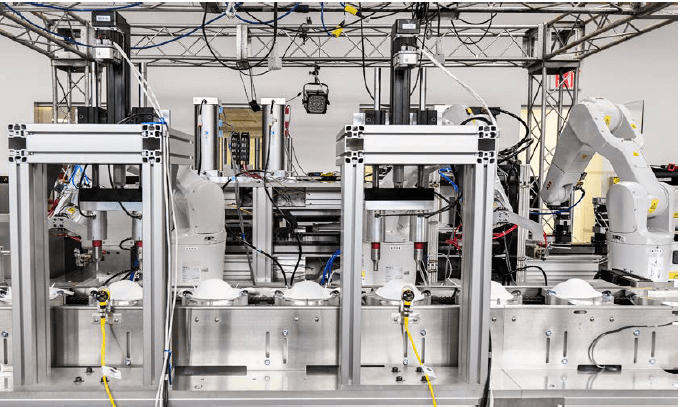

The workcell is designed so it can be adapted to make masks for a variety of medical

procedures. Shown: Mask workcell material infeed and transfer station. Photo: Tolomatic, Inc.

After a short development cycle, BTI is ready to launch a new generation of mask-making machine based on the automated workcell concept to improve efficiency, quality and throughput. A primary goal is to maximize output with the smallest footprint and fewest workers as possible. To make the venture successful, BTI assembled a team of component manufacturers with similar philosophies: fast response, flexible product solutions, ability to pivot to build an innovative solution to an immediate need. One of those companies, Tolomatic, Inc., based in Minneapolis, provided the linear motion control components—electric actuators—that move, form, index, cut and assemble the fabric into masks. Because of the two companies’ similar operating philosophies, Tolomatic could provide a wide variety of motion control actuators quickly and in the required configurable lengths and options. Another plus is that Tolomatic is located in the United States. BTI wanted to work with U.S. partners to build a machine made with U.S. parts for better quality, delivery and technical support.

Next-generation machine is small, fast and flexible

The BTI team researched mask-machine machines on the Internet and created a design to suit what they believed would yield the best results: a machine that is small, fast and flexible.

“All the mask-making machines we looked at were based on 20-year-old-designs; they are large, single-purpose machines,” said Tom Powell, vice president of Business Development. “They are expensive, they need lots of space, and you can’t get one in the near term. With new technology, we knew we could make a nimble machine with high-capacity throughput on a small footprint for a much lower cost of ownership compared to the big machines. Real estate is important in New York. We needed something highly configurable that would fit in as small a space as possible.”

The next-generation, custom-built, material-handling machine is expected to be FDA-approved and optimized to make a mask every few seconds, 24/7.

It was important to BTI that the machine be not only fast but also flexible. The machine can be easily modified to make different sizes of masks, such as smaller ones for children, and for different face sizes (think noses) and mask styles. Mask material can change, too – cotton or synthetic – as can strap material and length. “There’s no point in making a one-size-fits-all machine,” said Powell. “We built the machine so people can get what they want.”

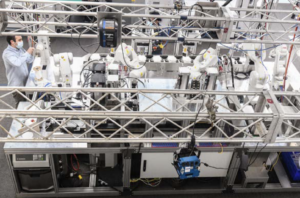

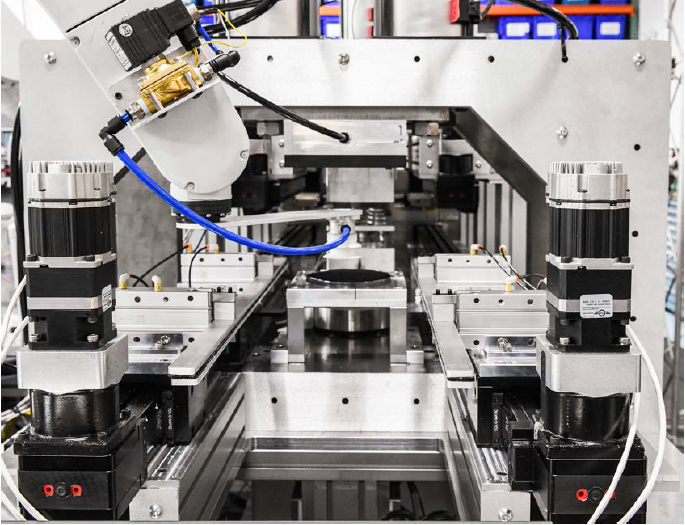

State-of-the-art motion control components provide the nimbleness and speed required for

fast and accurate throughput. Photo: Tolomatic, Inc.

Tolomatic in-step with fast-response approach

Although the machine’s footprint is small, its state-of-the-art motion control components – actuators, robots, PLCs, servo motors and drives, conveyors and EtherNet IT-based communication – provide the nimbleness and speed required for fast and accurate throughput. Robotic assembly and an automated production line allow the machine to easily adapt to different requirements.

BTI’s success is due in large part to its vertically integrated structure. It is also the reason the company can act quickly. Engineering, prototyping and manufacturing are integrated into one state-of-the-art facility. BTI makes much of its own equipment and components, from dyes to circuit boards. They also work closely with outside component manufacturers who can respond quickly.

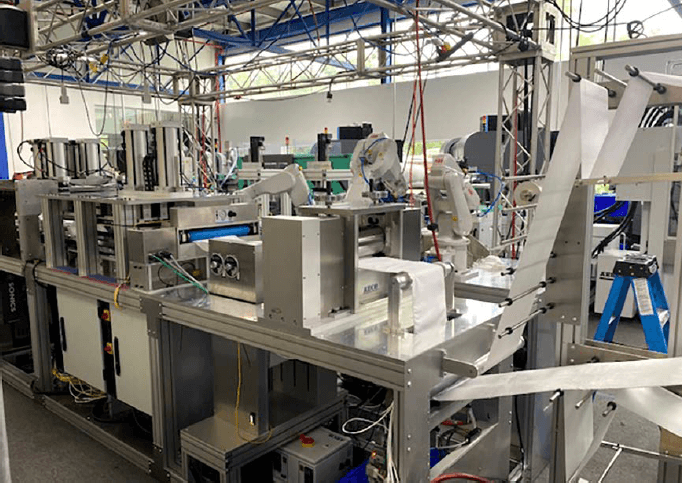

Tolomatic B3W actuators (horizontal actuators, in red boxes, top and bottom of mask former)

both move the material and support the heated form press. The unit is sealed to prevent

contamination from particulate. Photo: Tolomatic, Inc.

More than a dozen different Tolomatic electric actuators create the required linear motion for the machine, to feed, cut, shape and index the material. The actuators, selected according to requirements for force, load, speed, orientation and more, are configurable standard products, with flexible mounting and configuration options. However, all Tolomatic products are stroke-configurable, each made to the individual motion control requirement. The 200+-employee company is also vertically structured—it makes its full line of linear actuators and planetary roller screws at the Minneapolis facility. “Customers turn to Tolomatic for our reputation for quality and robust products, customer support and some of the fastest deliveries for build-to-order products in the industry,” said Andy Zaske, vice president of Sales and Marketing at Tolomatic.

“We are very much an inclusive company,” said Powell. “We work in a collaborative-partner relationship. That’s why we chose Tolomatic.

They’re in the room helping us make the machines. They make their own product and control their own supply chain. We didn’t have to go through a lengthy procurement process. Their catalogue products are stroke-configurable which allows us the flexibility we need. Plus, if we need something customized, we can get that, too.”

Linear motion components

The mask machine has three primary stages: material feed; form and cut; assemble and finish. This includes several stations, each with specific motion control requirements and axes of motion. From the initial material infeed and transfer station, the machine performs operations for form pressing, cutting and fabric welding. From there, the formed masks move to the assembly stations, where straps and nose pieces are cut, shaped and added to the mask molds. Final stations are for quality control inspection and packaging.

Each actuator is also sized with a motor mount specifically to fit Technic servo motors. Motor dimensions are pre-loaded in Tolomatic’s ‘Your Motor Here’ configurator, so the ordering and delivery of these units was very fast. Using the correct motor mount takes away the interface challenges and simplifies set-up.

At the first station, a Tolomatic B3W rodless belt-drive actuator moves and supports the material. The actuator pulls in the sheet of heavy material and then supports a heated form press that comes down on top of the sheet. It’s a large platform, so the actuator must provide high moment-loading capabilities as well as support and carry 100 pounds of weight from the press. The entire unit, including the internal carriage support and bearings, is completely sealed—there are no external guides—so this type of actuator design helps prevent fabric particulate from getting inside the actuator and eventually clogging up motion.

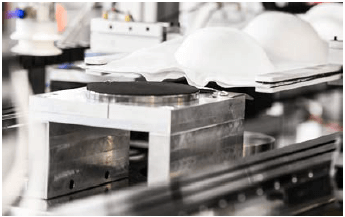

Tolomatic GSA actuators (positioned above masks) provide motion function to apply elastic ear straps.

Photo: Tolomatic, Inc.

At the second station, a Tolomatic B3W rodless belt-drive actuator also provides fast positioning in the move-and-support function, this time to support a press that cuts and welds the masks. The B3W rodless actuator can move at speeds up to 200 inches per second and support large moment loads to help facilitate production cycle times.

At the third station, B3W actuators then move the pre-formed masks to an ABB robot, which grabs them and swings them to the other side of the table for assembly. Robots cut and apply straps, and glue, cut and apply nose pieces. Two Tolomatic GSA linear slide actuators assist in the ultrasonic welding function that applies loop elastic for placing around ears. The masks are then unloaded for packaging and shipping.

“It was a team effort from all parties, from conceptual design to final assembly,” said Adam Farley, Northeast regional sales manager, Tolomatic.

Tolomatic GSA actuators (top, above metal frames) provide motion function to apply elastic ear straps. Photo: Tolomatic, Inc.

Looking beyond the pandemic

Charles Boyce started the company after managing large systems contracts for New York’s Metropolitan Transit Authority (MTA). BTI describes itself as an urban technology company that develops smart systems for city environments. The “Help Points” throughout the MTA are BTI innovations. BTI also develops life safety, security and communications equipment for MTA. Most of the electronics that exist in the New York subway system are made by BTI.

BTI bypasses traditional manufacturing methods: The company’s vertical structure relies on on-shore manufacturing and working with partners with similar strategies.

“If anybody is going to make ventilators or mask machines in a fraction of the usual development time, it’s going to be us,” said Powell. “We think a next-generation robotic mask machine workcell that is highly configurable makes sense. We did not do market studies or focus groups; we listened to the front-line healthcare professionals and just came to that conclusion on our own. In our business, time really does equal money. It’s important to us to have good local partners and U.S.-made equipment. We can make better systems and products that way.”

BTI is also thinking beyond the COVID-19 pandemic. The workcell is designed so it can be adapted to make masks for a variety of medical procedures. BTI has already had requests for non-COVID masks and specialty masks.

“We are looking at a whole host of new products around masks to help doctors facilitate procedures they can’t do now. We see an emerging market for custom masks for specific procedures.”

Tolomatic has a very similar philosophy about manufacturing and response to these types of challenges to our world. “We felt like we were uniquely positioned as an essential business, with fast and configurable products, to partner with companies like BTI to create the solutions needed for making masks, ventilators, new testing machines and other medical devices,” said Tolomatic’s Zaske.

Material moves through the forming section of the mask workcell. Photo: Tolomatic, Inc.

Ask an Engineer

Ask an Engineer