RSH Hygienic Electric Actuators

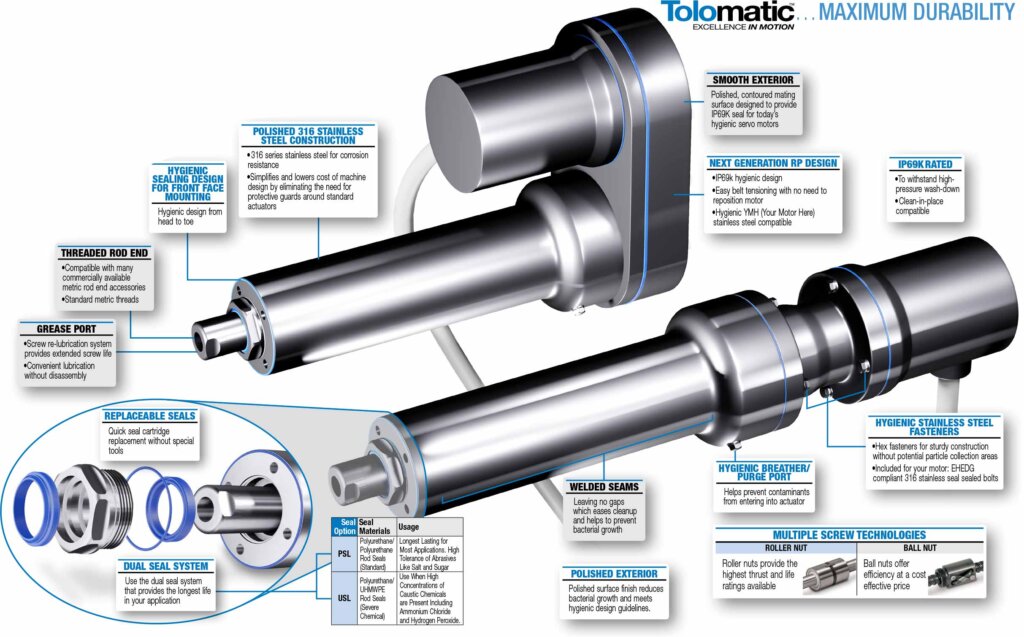

RSH hygienic electric actuators feature 316 stainless steel construction and an IP69K ingress rating.

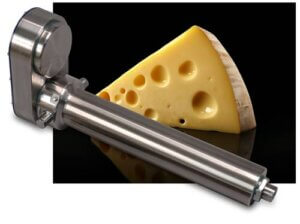

Tolomatic’s RSH line of hygienically designed stainless steel electric actuators are the perfect solution for food and beverage applications where higher forces are required for pressing, pumping, cutting or slicing. Standard motor mounts for a wide variety of stainless steel servo motor manufacturers, to make your system a complete Stainless Solution.

- 3 body sizes with 316 series stainless steel construction

- Force/thrust capabilities up to 7,943 lbf (35.3 kN)

- Stroke lengths up to 48 inches (1.2 m)

- Ball and roller screw options

- IP69K standard protection against high pressure washdown

Features & Ordering

Download the RSH Brochure for full details on features

RSH Features

RSH Ordering

Specifications

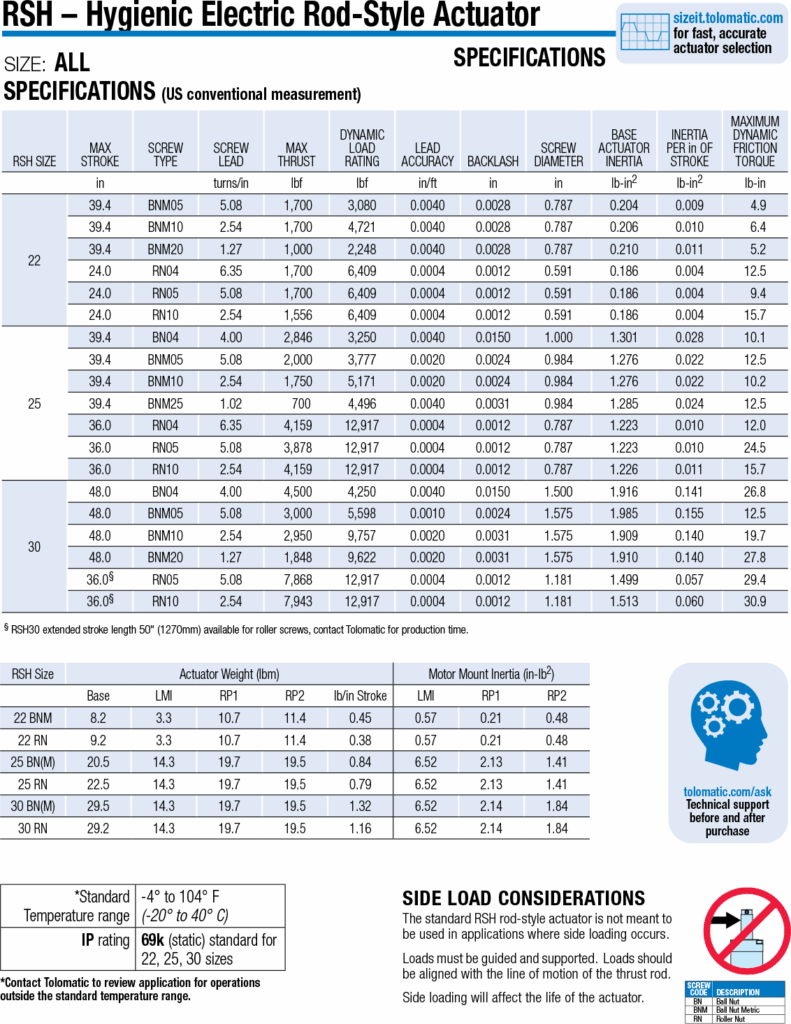

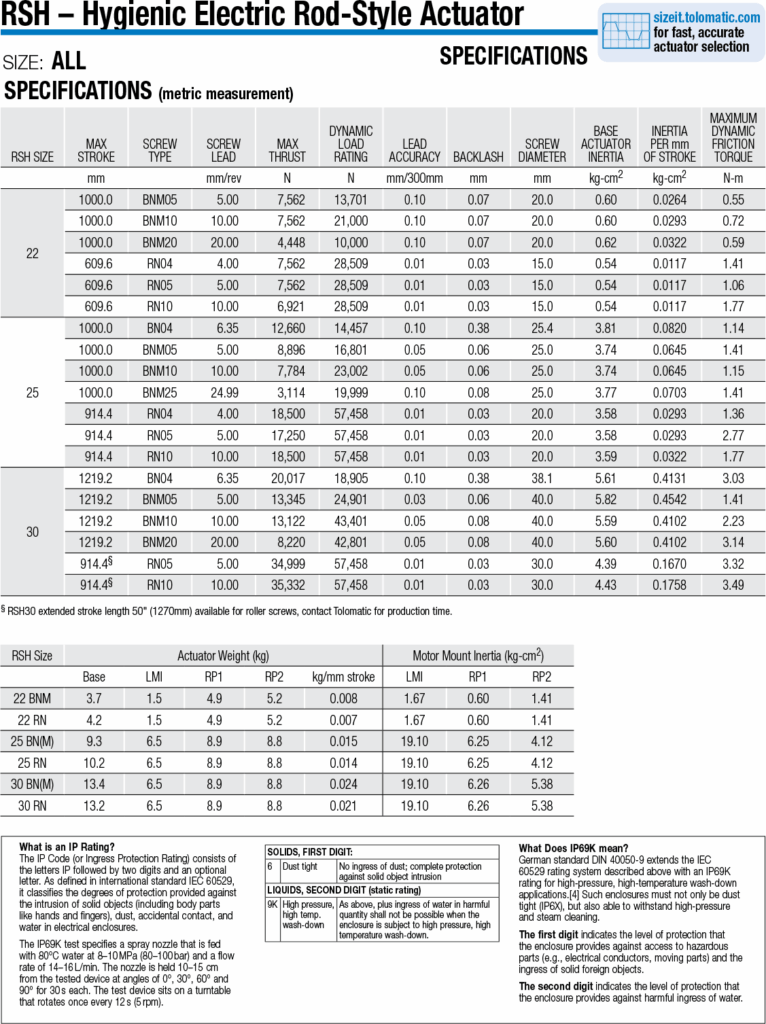

| Size | Units | RSH22 | RSH25 | RSH30 |

|---|---|---|---|---|

| Maximum Stroke | in (mm) | 39.4 (1,000) | 39.4 (1,000) | 48 (1,219) |

| Maximum Force | lbf (N) | 1,700 (7,562) | 4,159 (18,500) | 7,943 (35,330) |

| Maximum Speed | in/sec (mm/sec) | 19.6 (498) | 19.6 (498) | 19.6 (498) |

Specifications RSH Hygienic US Measurements

Specifications RSH Hygienic Metric Measurements

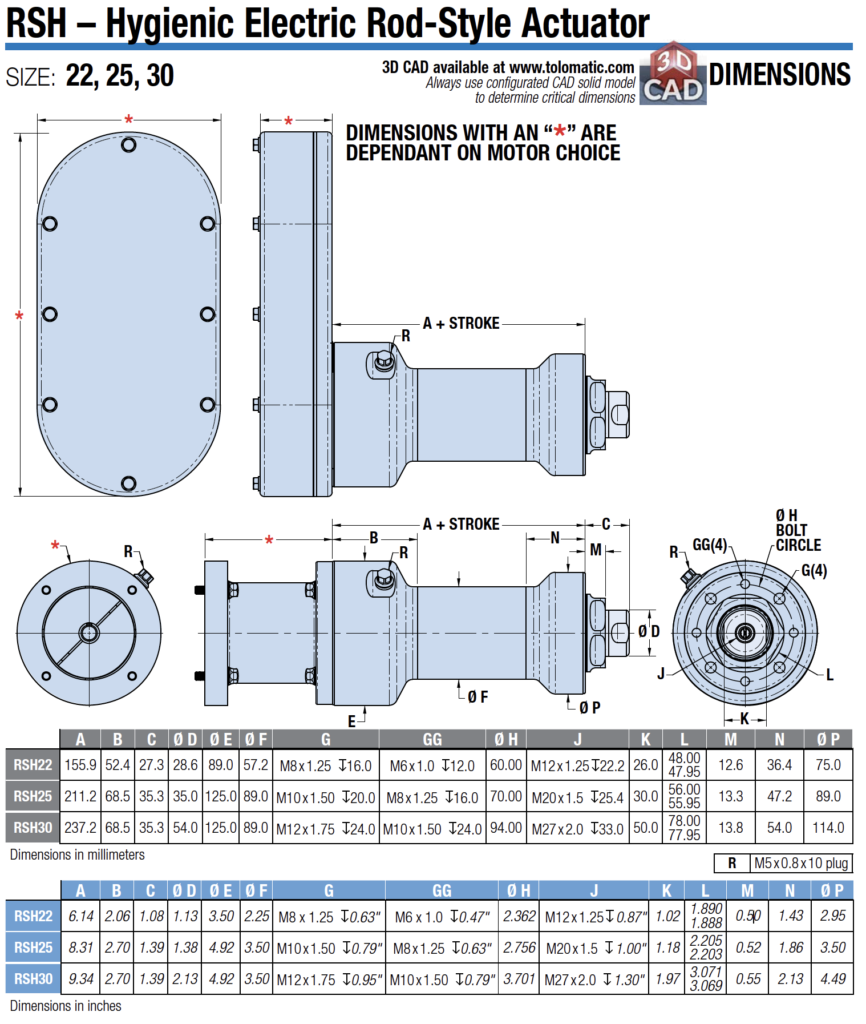

Dimensions

RSH 22, 25, 30 Dimensions

Get CAD

Manuals & Part Sheets

Additional Resources

Information Center:

Application Checklists

Catalogs & Brochures

- Corporate Overview-Linear Motion Solutions Brochure (English)

- SOLUCIONES DE CONTROL DE MOVIMIENTO (Spanish, Corporate Overview-Motion Control Solutions Brochure)

- Unternehmensübersicht (German, Corporate Overview brochure)

- 公司概述 (Chinese, Corporate Overview Brochure)

- RSH Hygienic Electric Rod Style Actuator Brochure

- Actuador eléctrico higiénico de varilla RSH (RSH brochure, ES)

- Aplicaciounes de la Ind. Automotriz (Auto Appl SP)

- Electric Pressing Solutions Brochure

- Food & Beverage Solutions Brochure (English)

- Soluciones para Alimentos y Bebidas (Spanish, Food & Beverage Solutions Brochure)

- Broschüre zu Lebensmitteln und Getränken (German, Food & Beverage Solutions Brochure)

- Food & Beverage Solutions Brochure (Japanese)

- Medical and Life Sciences brochure

- RSH Elektrischer Hygienischer Schubstangenantrieb (RSH catalog ^DE)

Certifications

E-Books

- E-Book: A Resource on Electric Linear Actuators: What a machine designer needs to know

- E-Book: Literatura Sobre los Actuadores Lineales Eléctricos

- E-Book: Diseño de Movimiento Lineal - Actuadores Eléctricos para Sustitución de Hidráulica

- E-Book: Electric Actuators for Hydraulic Replacement

- Buch: Elektrische Stellantriebe als Ersatz für hydraulische Antriebe (E-Book: Electric Actuators for Hydraulic Replacement; DE)

Flyers

Guides

- Selecting the Optimal Screw Technology

- Actuator Life: How to estimate for ball and roller screw actuators

- INFOGRAPHIC: Accuracy and Repeatability in Linear Actuators

- INFOGRAPHIC: Calculating Total Cost of Ownership

- INFOGRAPHIC: Ten Tips for Specifying Electric Rod Actuators

- How to Convert Hydraulic Cylinders to an Electric Actuator Alternative

- Guide to Third Party Motor Integration

Tech Bulletins

Terms & Conditions

Videos

White Papers

- Top Ten Tips: How to specify electric rod-style actuators for optimal performance, reliability and efficiency

- Electric actuators vs. pneumatic cylinders: A comparison based on total cost of ownership

- Select the right linear actuator: Making sense of manufacturer specifications

- Rules of actuator and guide alignment in linear motion systems

- IP ratings and the manufacturing environment: How to apply linear actuators for quality, safety and long service life.

- Minimizing electrical noise in actuator drive systems for maximum reliability and performance

- Introduction to accuracy and repeatability in linear motion systems

- Evaluating actuators for washdown in food & beverage applications

- Electric Rod Actuators vs. Hydraulic Cylinders: A Comparison

- A technical comparison: Performance of pneumatic cylinders and electric rod actuators

- How roller-screw and ball-screw actuators compare in high-force applications

- Top 5 best practices for designing electric actuators into food processing equipment

- Designing Gantry and Multi-Axis Automation Systems

- Diez Consejos Óptimos: Cómo especificar los actuadores eléctricos de vástago para obtener rendimiento, confiabilidad y eficiencia óptimos

- Comparación de la tecnología de los actuadores eléctricos: Diseños integrados y tradicionales

- Medical Device Motion Design Considerations

- Integrierte und traditionelle Bauweisen Weißbuch (DE, Integrated and traditional designs WP)

- Making the Jump to Electric

Success Stories

Additional RSH information

Tolomatic’s line of hygienically designed all stainless steel electric actuators offer up to 7,943 lbf (35.3 kN) and they are the perfect solution for food and beverage applications where higher forces are required for pressing, pumping, cutting or slicing. Use the Tolomatic Your Motor Here® database to select from a wide variety of stainless steel motor manufacturers for a complete all stainless package.

- 3 body sizes with 316 series stainless steel construction

- Ball and roller screw options

- Force/thrust capabilities up to 7,943 lbf (35.3 kN)

- Stroke lengths up to 48 inches (1.2 m)

- IP69K, clean in place compatible

Ask an Engineer

Ask an Engineer