Automotive & Transportation Electric Actuators

Electric Linear Actuators for Automotive Manufacturing

High Duty Cycle Linear Motion for Precision and Reliability

Rigorous production and quality required by automotive manufacturers demand innovative, high duty cycle linear actuator solutions for precision and reliability. Tolomatic’s broad product line of linear actuators meet production challenges throughout the automotive supply chain. If existing designs don’t meet a unique automotive production challenge, our engineering staff can design an actuator that does.

Our engineering experts stand ready to collaborate with customers to tailor customized solutions to meet their motion challenges. Developing electric linear actuators designs to meet customer needs is in our DNA at Tolomatic. Start the conversation, Ask an Engineer.

Where are Tolomatic Electric Linear Actuators Used

in the Automotive Industry?

Our electric linear actuators meet application challenges faced by manufacturers throughout the automotive production process — including welding, pressing, vehicle fabrication, assembly and beyond. Some examples:

- Press Shop – Metal forming, handling, die exchanges, packing, part transport

- Body Shop Assembly – Clamping, welding, resistance spot welding, adhesive dispensing, clinching, hemming

- Paint Shop – Dispensing paint, adhesive and sealants, spraying insulation

- Final Assembly – Conveying, lifting stations, part positioning, pressing

- Quality Inspection – Positioning of inspection systems

In automotive component manufacturing by Tier 1 and Tier 2 suppliers, our electric linear actuators can meet even the toughest demands. Did you know our RSX High Force Electric Linear Actuators can handle forces up to 66,000 lbs.? Other application examples include:

- Injection molded parts – Part ejection, mold positioning, part handling, pick & place

- Powertrain – Honing, conveying, part positioning, pressing, forming and bending

- Batteries and trays – Micro and projection welding, crimping, pressing, tray welding

- Electronic components – Pick & place, pogo pin testing, sorting, camera for parts inspection

- Interior components – Welding, forming and bending, cutting, testing

- Exhaust system components – Tube bending, welding, tube flaring, parts insertion, crimping

- Tires – Product feeder, rubber cutting, tire turn-up, green tire transfer

Automotive & Transportation Success Stories

Application Description: Pull Tester Assembly – Pull test for steering/strut linkage assemblies

Application Description: Positioning a thermal welding device and camera system that verifies each weld for quality.

Application Description

An actuator to steer the wheels of a high-speed train car, to reduce the wear caused by curves in the track.

Product Used: Modified IMA44 Integrated Linear Servo Actuator

Product Type: Modified Standard

Product Family: Electric

Product Used: GSWA ServoWeld® Actuator

Product Family: Electric

Product Used: RSA Rod Actuator

Product Family: Electric

Product Used: JVL Servo Motor and RSA Actuator

Product Family: Electric

Product Used: Custom

Challenge: Raising a metal parts stamping safety cage

Product Family: Pneumatic

Product Used: MXP40N Band Cylinder

Challenge: Diesel fuel filter cleaning

Product Family: Pneumatic

Product Used: MXP-S long stroke pneumatic air cylinder

Challenge: Assembling cartridges for air bag deployment.

Product Family: Electric

Product Used: RSX Extreme Force Electric Linear Actuator

Challenge: Wheel bearing press.

Product Family: Electric

Product Used: RSX Extreme Force Electric Linear Actuator

Product Family: Electric

Product Used: RSA & RSX Actuators

Challenge: Resistance spot welding (RSW) chassis

Product Family: Electric Rod Style Actuator

Product Used: CSWX

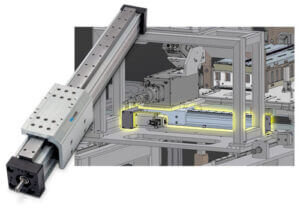

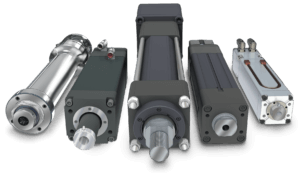

RSA electric linear rod actuators feature accurate and high force performance, making them ideal for replacing pneumatic & hydraulic cylinders. These electric linear actuators feature acme, ball or roller screw selections, with enhanced high thrust bearings and heavy duty internal bumpers. A rigid, strong aluminum housing allows for easy mounting of switches and sensors. RSA actuators are suitable for general motion control, valve actuation, punch press, injection molding and many more applications.

Design that combines an electric rod actuator with guide rods, mounting blocks, and bearings. Ideal for applications requiring guidance and support of the load. Forces up to 950 lbf (4.2 kN).

Integrated spot welding actuators offering a spot welding solution for forces up to 3,300 lbf (14.7kN).

MXP-N internal bearing compact air cylinder offers a space-saving design over typical rod type air cylinders.

The MXP-S solid bearing long stroke pneumatic air cylinder offers a large carrier mounting pattern for load stability.

Hydraulic-class electric linear actuators that are roller screw driven, and provide extremely high forces, precision, and long life. Ideal for hydraulic replacement. Forces up to 66,000 lbf (294 kN).

Ask an Engineer

Ask an Engineer