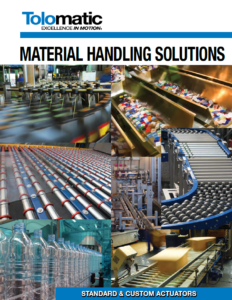

Material Handling Linear Actuators

Electric Linear Actuators for Material Handling

Material Handling Applications

with Electric Linear Actuators

Material handling and packaging have been a key sector of Tolomatic’s business since 1954. Today’s applications span the supply chain from raw material handling, single unit packaging, conveying and palletizing to order fulfillment and logistics and beyond. Tolomatic electric actuators are applied to virtually every axis of linear motion in these applications. Applications like:

- Packaging – Boxing, bagging and sealing, stacking, pressing, height adjustment, indexing, positioning, gantry system pick and place, label placement

- Conveying – Sorting, shuttling, escapements, height adjustments, diverting, kick offs, side guiding, swing arms, height adjustment, gantry system pick and place, transfer stations

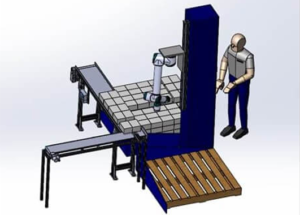

- Palletizing – Stacking, positioning, height adjustment, lifting, gantry system pick and place, wrapping/unwrapping

- Order fulfillment & logistics – Pick and place, height adjustments, autonomous guided vehicle (AGV) functions for everything from cartons to freight containers

Tolomatic offers a full range of pneumatic and electric actuator designs. However, the advantages of electric linear actuators are becoming more important as productivity demands and total cost of ownership become stronger driving forces. Electric actuators provide clean, consistent, control with no air, no oil, no leaks to jeopardize productivity or quality. In today’s fast-paced production environments, electric linear actuators provide control for efficient product change-over flexibility, without iterative adjustments.

Advantages of Electric Linear Actuators

for Material Handling

Tolomatic offers a full range of pneumatic and electric actuator designs for material handling applications. However, as productivity demands and total cost of ownership become more critical considerations, the advantages of electric linear actuators are gaining importance. These include:

- Clean, continuous control with no air, no oil and no leaks that could jeopardize quality

- Control for efficient product change-over flexibility without iterative adjustments

- Reliability that doesn’t jeopardize productivity or quality

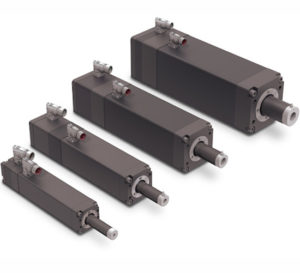

- Options like the IMA Linear Servo Actuators with a unique integrated servo motor design that’s well suited to the variability of material handling applications

With a full line of rod style, rodless, and IP69K actuator solutions — all built-to-order — Tolomatic is an ideal partner for engineering collaboration on material handling machine designs.

Reach out to our team of application engineers to optimize linear motion in your application: Ask an Engineer

Product Family: Electric

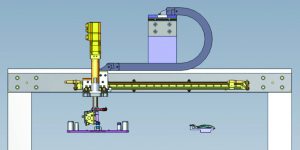

Product Used: ERD Rod Cylinder

Product Family: Pneumatic

Product Used: BC2 & MXPS

Product Family: Electric

Product Used: MXB-P

Product Family: Electric

Product Used: B3W15

Product Family: Electric

Product Used: ERD15

Product Family: Electric

Product Used: MXE, ERD

Challenge: Automating product change-over on bottling conveyor.

Product Family: Electric

Product Used: ERD

Challenge: Control of waste removal door on a high speed pizza conveying machine.

Product Family: Electric

Product Used: B3W10

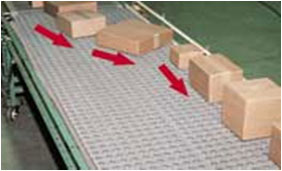

Challenge: Diverting boxes to different conveyors.

Product Family: Pneumatic

Product Used: BC2 Rodless Cylinder

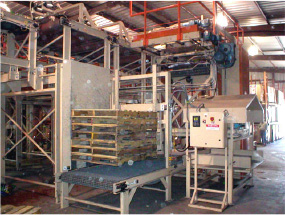

Challenge: Slip sheet placement on pallets for palletizing

Product Family: Pneumatic

Product Used: MXP32

Challenge: Accurately position boxes in filling station then, after filling is completed, move boxes onto conveyor leading to packaging station.

Product Family: Pneumatic

Product Used: BC2 Rodless Band Cylinders

Challenge: Indexing conveyor transfer station

Product Family: Electric

Product Used: ERD Rod Style Actuator; MXP Profiled Rail Pneumatic Actuator

Challenge: A manufacturer of fiberglass automation equipment was using pneumatic cylinders to control the vertical roller and the winding roller used to package fiberglass insulation into rolls.

Product Family: Electric Rod-Style Actuator

Product Used: RSA

Application Description:

Convert the conveyor packer, located at the end of the conveyor, from pneumatic cylinders to electric actuators. Motions required include: several high-speed push operations, a centering operation, a tipping operation, and a container lift operation.

Challenge: Lane diverting system for sorting items.

Product Family: Electric

Product Used: ERD

Challenge: Directing product to secondary conveyor line.

Product Family: Electric

Product Used: RSA32 Electric Linear Actuator

Challenge: Diverting and sorting various size auto and truck tires during manufacturing.

Product Family: Pneumatic

Product Used: MXP63P Rodless Band Cylinder with Profiled Rail Bearing

Challenge: Position adjustment for de-nesting pallets.

Product Family: Electric

Product Used: ERD Electric Linear Actuator

Product Family: Electric

Product Used: RSA Rod Actuator

Electric rod actuator integrated with a servo motor in a single, compact design that integrates with 3rd party drives and accessories. Forces up to 8,044 lbf (35.8 kN).

RSA electric linear rod actuators feature accurate and high force performance, making them ideal for replacing pneumatic & hydraulic cylinders. These electric linear actuators feature acme, ball or roller screw selections, with enhanced high thrust bearings and heavy duty internal bumpers. A rigid, strong aluminum housing allows for easy mounting of switches and sensors. RSA actuators are suitable for general motion control, valve actuation, punch press, injection molding and many more applications.

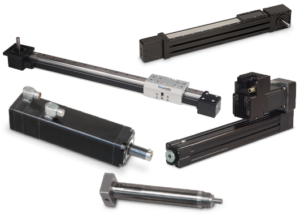

BC2 pneumatic band cylinders provide multiple mounting options and a wide variety of load carrying capacities.

The MXP-S solid bearing long stroke pneumatic air cylinder offers a large carrier mounting pattern for load stability.

Linear actuator that uses a profiled rail bearing and belt drive train to move heavy loads at high speeds. Loads up to 1,290 lbs (586 kg).

B3W linear belt drive actuators have an enclosed ball bearing design for heavy loads, high bending moments, and long service life.

Ask an Engineer

Ask an Engineer