Medical & Life Science Linear Actuators

Electric Linear Actuators for Medical & Life Science Applications

Streamline Time to Market

with Electric Linear Actuators for Medical Equipment

In the medical and life science industries, equipment design engineers often have to face unique challenges and stringent regulatory requirements. The design cycle and time to market can be long, requiring extensive iterations along the way. Tolomatic has long-standing relationships with medical and life science equipment OEMs, proving that we are reliable partners who understand their challenges. We often deliver value-added services (subassembly) to simplify BOM’s for OEM’s and machine builders.

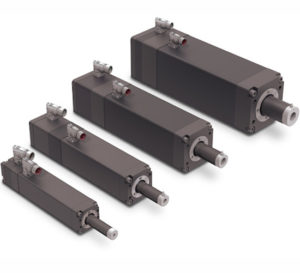

Our broad array of linear actuators — some, like the stainless steel IMA-S series, with a built-in servo motor — meet everyday challenges in the medical field with standard actuator designs that are stroke and option configurable. Built to order, built to last.

If existing designs don’t exactly meet a unique challenge, our engineering team can design an actuator that does. Tolomatic’s manufacturing facility is state-of-the-art and has the latest in inspection equipment — plus, our quality system is ISO 9001 certified. Our greatest successes result from engineer-to-engineer collaboration with our customers to refine or create an entirely new medical linear actuator design. Collaboration with customers is part of our DNA at Tolomatic. Let’s solve it together…start the conversation: Ask an Engineer.

Let’s solve it together. Start the conversation: Ask an Engineer

Examples of Medical & Life Science Applications

for Tolomatic Electric Linear Actuators

Tolomatic electric linear actuators deliver clean, consistent, control of motion in applications ranging from patient care equipment to manufacturing processes for medical supplies. Some examples include:

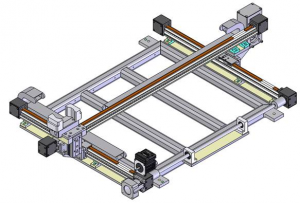

- Laboratory equipment – Gantries for pick and place in sample testing

- Physical Therapy equipment – Positioning and resistance adjustment for patient rehabilitation

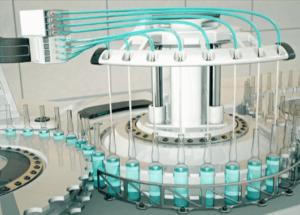

- Pharmaceutical manufacturing – Filling, depositing, aseptic liquid dispensing, sorting, packaging, blow molding

- Catheter manufacturing – Material handling, positioning, coating

- Medical supply production – Ultrasonic welding, cutting, folding, material handling, packaging

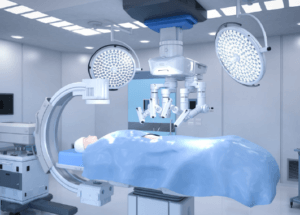

- Surgical procedure equipment – Patient positioning, injection of contrast media, steam, saline and other required substances, aspiration

- Radiology equipment – Patient positioning, scanning, energy range control and radiation beam focus adjustment

Medical & Life Science Success Stories

Application Description

Filling machine that requires frequent container changes and wash-down

Product Family: Electric

Product Used: ERD20

Product Type: Standard

Product Family: Electric

Product Used: Custom Electric Screw Actuator

Product Family: Electric

Product Used: Rod-Style Actuator

Product Type: Custom

Product Family: Electric

Product Used: RSA Rod Actuator

Product Family: Electric

Product Used: B3W Belt Drive Actuator

Product Family: Electric

Product Used: B3S Screw Drive Actuator

Challenge: Apply pressure points to counter muscle atrophy.

Product Family: Electric

Product Used: ERD15

Challenge: Electric actuator was used to adjust the focus of radiation beams used to treat cancer cells.

Product Family: Electric

Product Used: Custom Electric Rod Style Actuator

Challenge: Applying ultrasonic welds to large medical waste bags

Product Family: Electric

Product Used: B3W Linear Belt-Drive Actuator and IMA Linear Servo Actuators

Challenge: Accurately position small plastic tubes for coating.

Product Family: Electric

Product Used: B3S Ball Screw Linear Actuators & MXB-P Heavy Duty Linear Actuator

Challenge: Automatic pill sorting for large retailers.

Product Family: Electric

Product Used: MXB-P Heavy Duty Linear Actuator

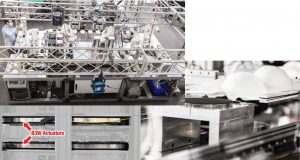

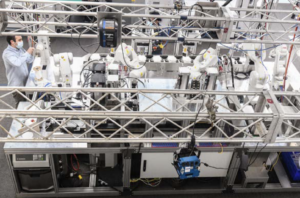

Challenge: Create a new generation mask-making machine based on the automated workcell concept to improve efficiency, quality and throughput.

Product Family: Electric

Product Used: B3W Rodless Actuators & GSA Guided Rod Actuators

Challenge: An OEM manufacturer that makes high end resistance weight training equipment for fitness facilities needed actuators that slowly push or pull to provide the exact amount of resistance for the exercise.

Product Family: Electric Rod-Style Actuator

Product Used: ERD

Challenge: Operation of door/gate to index vials prior to sealing.

Product Family: Electric Actuators

Product Used: IMAS

Product Family: Electric

Product Used: ERD SS2 & ACS Stepper Driver

Challenge: Equine X-ray CT imaging with rapid 3D imaging of the lower limbs and head without subjecting the horse to general anesthesia.

Product Family: Electric Rodless Actuator

Product Used: MXE-S

Product Family: Electric

Product Used: RSA12 Electric Rod Actuators

Product Type: Modified Standard

Application Requirements:

Stroke: 154.9 mm (6.1″)

Speed: >25.4 mm/sec (>1.0″/sec)

Thrust: 448 N (100 lbf)

B3W linear belt drive actuators have an enclosed ball bearing design for heavy loads, high bending moments, and long service life.

Tolomatic B3S ball screw linear actuators have an enclosed ball bearing design that accommodates heavy loads, high bending moments to deliver long service life.

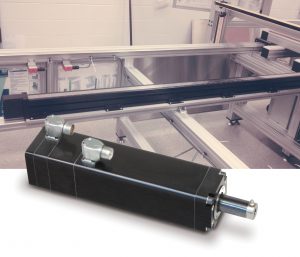

RSA electric linear rod actuators feature accurate and high force performance, making them ideal for replacing pneumatic & hydraulic cylinders. These electric linear actuators feature acme, ball or roller screw selections, with enhanced high thrust bearings and heavy duty internal bumpers. A rigid, strong aluminum housing allows for easy mounting of switches and sensors. RSA actuators are suitable for general motion control, valve actuation, punch press, injection molding and many more applications.

Electric rod actuator integrated with a servo motor in a single, compact design that integrates with 3rd party drives and accessories. Forces up to 8,044 lbf (35.8 kN).

Combines a hygienic electric rod actuator and motor into one package. It is IP69K, built with 316 SST, and works with 3rd party drives and accessories. Forces up to 2,500 lbf (11.1 kN).

Economical electric rod cylinder that is compatible with NEMA & metric mount stepper and servo motors. Ideal for pneumatic replacement. Forces up to 500 lbf (2.2 kN).

Linear actuator that uses a profiled rail bearing and belt drive train to move heavy loads at high speeds. Loads up to 1,290 lbs (586 kg).

Ask an Engineer

Ask an Engineer