Accuracy and repeatability. Only pay for what you need.

By Tolomatic on October 30, 2018

When a machine’s design calls for an electric linear actuator, most design engineers want to know about an actuator’s accuracy and repeatability…with emphasis on accuracy.

When a machine’s design calls for an electric linear actuator, most design engineers want to know about an actuator’s accuracy and repeatability…with emphasis on accuracy.

Designers are looking for a simple answer, but there’s a lot to accuracy. It’s more than just a number a manufacturer can claim. Accuracy is dependent on several factors, not the least of which is the application itself.

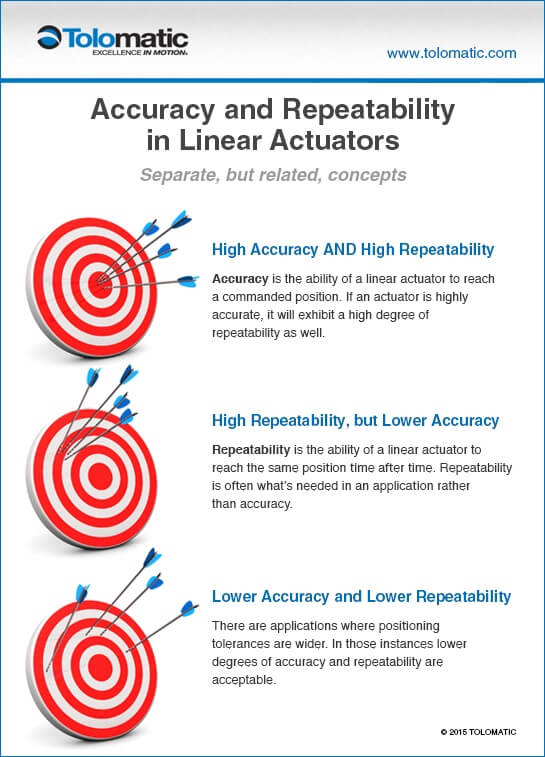

Interestingly, with all the focus on accuracy, a basic truth can be forgotten: repeatability (or predictability) may be what’s needed. Also, accuracy can be expensive. Repeatability is more budget-friendly.

For a thorough exploration of this topic, please download our white paper, Introduction to accuracy and repeatability in linear motion systems. And download the file of our accuracy and repeatability infographic.

What is accuracy?

Here’s a straight-forward definition: accuracy is the ability of an actuator to achieve a specified position. All the arrows hit the bullseye.

In real life manufacturing, many factors can influence accuracy. Factors like:

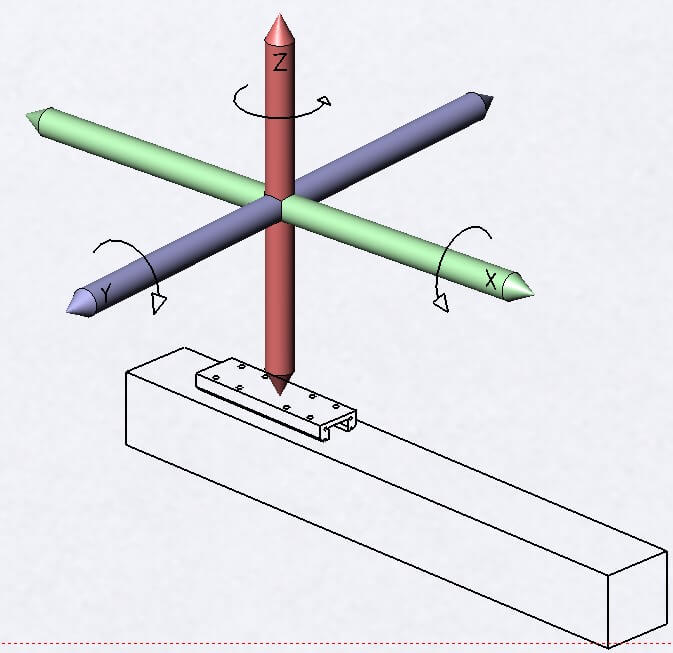

- Degrees of freedom A designer needs to know the application’s requirements for accuracy on six axes since an electric actuator has the possibility for error in six degrees of freedom:

- X axis (back and forth)

- Y axis (side to side)

- Z axis (up and down)

- Rotation around each axis

- System components The design engineer will need to understand how the components of an electric linear actuator can affect accuracy. For example, machined housings are manufactured to tighter tolerances than extruded housings. Roller screws are more accurate than either ball or acme screws. Even motors can affect accuracy in electric linear motion systems.

- Mounting and orientation A machine designer may need to consider mounting and orientation since they can affect accuracy along selected axes. For example, anchoring an actuator to a known flat surface could eliminate errors due to bowing and twisting (distortion on the Y and Z axes).

The bottom line is that accuracy can be expensive. Higher performance actuator components like machined housings and roller screws cost more. The designer will have to weigh all the application’s needs to know if accuracy’s what’s needed or something else, like repeatability.

What is repeatability?

Simply put, repeatability is the ability of an actuator to achieve a given position time after time. Repeatability is the same as predictability, an important characteristic in an automation component. It may not be the bullseye, but you hit the same spot again and again.

Be a budget hero

Don’t pay for more capability than your application calls for. If you take a close look, you may find that what you need is not accuracy so much as a high degree of repeatability or predictability. If you can control the actuator’s accuracy through mounting and other means, you may be able to use a more economical model. That could lower overall system costs and make you a hero!

Ask for help and advice from your linear motion supplier. These experts are there to help you.

Resources

For a thorough exploration of this topic, please download our white paper, Introduction to accuracy and repeatability in linear motion systems. And download the file of our accuracy and repeatability infographic.

Ask an Engineer

Ask an Engineer