How accurate is an actuator?

Accuracy and repeatability are two separate but related concepts of a linear motion system. The motor, drive and electric actuator itself all influence accuracy and repeatability. It’s quite possible you may need repeatability more than accuracy.

Easy as pie

Five best practices for designing and installing electric actuators in food processing equipment help create open/clean-in-place designs.

Stop Motion or High Definition?

It was a rough week for the whole team working on a new customer’s new machine design. Finally, it’s Friday night and you sit down on the couch to relax with your friends. You made some popcorn and just popped in a DVD recommended by your parents. They told you it’s a classic and might be a bit slow but it has a good story. The movie starts and after 30 seconds, your friends are giving you confused looks. The movie is very difficult to watch because it is filmed in stop motion. The images on the screen are frozen and jump from one to the next. Sometimes it is half a second between shifts and sometimes it can be several seconds. You can see the evening disintegrating and quickly move to switch out the movie to ‘The Fast and the Furious’ for some non-stop action.

Failure not an option? How to avoid premature linear screw actuator failure

Some components are more mission-critical than others. A main worry of machine design engineers is making equipment that will last and avoiding need for field service calls to diagnose issues and replace failing components. At their core, electric linear screw actuators deploy mechanical technology such as ball bearings, ball screws and roller screws that have a finite life. These components do not last forever, even though that is the expectation of some customers. When asked “How long will this actuator last?” we provide our customers with a way to calculate, estimate and size the electric linear screw actuator to achieve the desired life for their applications.

Accuracy and repeatability. Only pay for what you need.

When a machine’s design calls for an electric linear actuator, most design engineers want to know about an actuator’s accuracy and repeatability…with emphasis on accuracy.

Electric rod actuators add accuracy and repeatability to PCB manufacturing

Some manufacturing processes require high precision -- printed circuit boards (PCB) production, for example. In these instances, the capabilities of each component in a production system are critical. Although machine designers know pneumatic cylinders well, these cylinders struggle to deliver the accuracy and repeatability demanded by high precision processes. Many design engineers now turn to electric rod actuators for accuracy and repeatability and for better operating efficiency.

Electric linear actuator accuracy and repeatability webinar

When an engineer is developing a machine design, accuracy is often top-of-mind. So is machine cost. But these two considerations can be at odds since the usual scenario is that the higher the accuracy of a device, the higher the cost. This certainly holds true for electric linear actuators and linear motion systems.

Electric linear actuators deliver precise positioning for aerospace welding

Precision is integral to the aerospace and defense industries. Even a seemingly insignificant element of a device may be mission-critical, requiring the tightest manufacturing tolerances. That’s why when a rocket manufacturer contacted us about electric linear actuators that could hold their fuselage components in place for welding, we knew precise positioning would be a requirement.

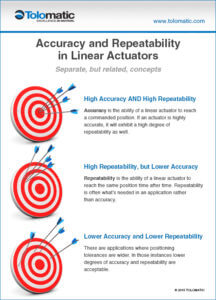

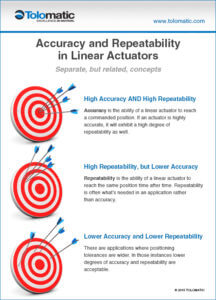

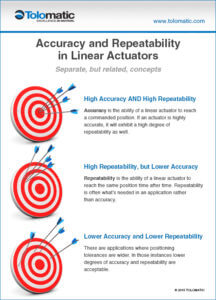

[INFOGRAPHIC] Accuracy and repeatability in linear actuators

Machine builders frequently ask us, “How accurate is this actuator?” The answer is more than a number found in the product’s specifications. The real-world answer is much more complex.

In the real world of manufacturing, a greater degree of accuracy can come with a higher price tag. Sometimes you just need repeatability in your application, and that can be less costly. We urge you to thoroughly study the requirements and parameters of each application before selecting an actuator. Understanding the specific needs of each application will help you avoid excess costs and design a system with the best overall value.

Ask an Engineer

Ask an Engineer