Actuator know-how for machine design engineers, Part 2

Machine designers face a variety of options when selecting linear actuators. It all comes down the best fit for the application: what solution provides the best results at a cost– effective price.

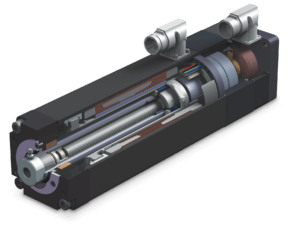

Roller screw technology for electric actuators

The unique design of a roller screw actuator offers longer life and higher thrust in a smaller package compared to ball screw actuators, increasing a machine designer’s ability to create compact machine concepts.

The Big Era of electromechanical linear actuators

Traditionally, hydraulic power is the go-to answer for heavy lifting. Now, high-force electric actuators have overtaken hydraulics in terms of flexibility, precision and reliability.

High-force linear actuator makes muscle car simulation possible

Tolomatic linear actuators are used worldwide in a myriad of industries for automation tasks like conveying, sorting, filling and more. Beyond conventional industrial applications they are also used in demanding, non-industrial applications. Some of these, such as simulators for flight, driving, testing and entertainment, require high-frequency moves to create a realistic experience. Here’s one such story, in which our electric high-force linear actuators helped simulate the experience of popping a wheelie in a true muscle car.

High-force linear actuators. Roller screws vs. ball screws

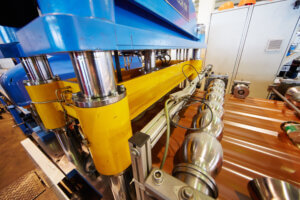

Not too long ago the only solution for high-thrust linear motion was fluid-powered cylinders that used high-pressure air or hydraulic oil. Although these cylinders could provide the force required, they could not deliver on requirements for infinite positioning, speed control, and low maintenance.

Now there are electric rod actuators that deliver high forces and excel at the other criteria as well. Often these electric high-force linear actuators utilize ball or roller screws. However, it’s a challenge to choose the right screw technology for a high-force application.

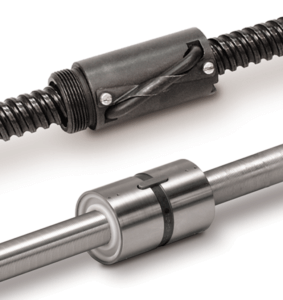

Electric high-force linear actuator choices. Ball vs roller screw

Many applications require high-force linear actuators – from moving equipment in a foundry to powering a press in metal forming to guiding heavy logs in a sawmill. Whatever the application, a machine designer is faced with a choice…whether to specify a ball or roller screw in the electric high-force linear actuator.

Extreme force electric linear actuator controls lumber drying

The lumber processing industry demands rugged, strong, reliable and accurate equipment in all its operations. Machine designers who serve this industry need extreme force linear actuators to move heavy loads. Hydraulic cylinders have been the go-to, but they have limitations, such as poor control, leaks, temperature sensitivity, maintenance requirements and lack of feedback. Now there are electric rod actuators powered by roller screws that can meet the requirements of these high force applications.

Which is best for high force linear actuators: Ball or roller screws?

If you’re selecting an electric high force linear actuator, you may believe you know the answer to the question in the headline. The force transmission prowess of roller screws is well known. But before you go to the expense of a roller screw linear actuator, take a careful look at the application. You may find that a ball screw actuator will do the job. And that could mean significant savings.

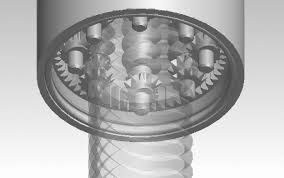

Roller screws for high force linear actuators. What type’s best?

Selecting the best screw type for a high force linear actuator can seem a daunting task, but it doesn’t have to be. Start with our Guide on the three common screw types for electric actuators, their advantages and disadvantages.

Acme, ball and roller screws for electric linear actuators

When you’re specifying a screw-driven electric linear actuator, you’ll need to consider the type of screw that best meets the needs of your specific application. Some manufacturers give you a choice so you can tailor the device precisely, and that’s a good thing since applications differ widely.

The basic types you’ll have to choose from are roller screws, ball screws and acme screws. There’s quite a lot a machine designer needs to know about these electric actuator screw types and how to select the right one. We offer a guide that helps your decision-making.

Electric high force linear actuators with roller screws rival hydraulic

When you’re specifying a high force linear actuator, your application’s requirements call the shots. It used to be that hydraulic cylinders were your only recourse when high force was needed. Now there are electric linear actuators with roller screws that rival the high force, high thrust, high torque capabilities of hydraulics. Plus, these electric actuators deliver high speed, great accuracy and repeatability and long life. Electric roller screw actuators are definitely an alternative to consider.

High force linear actuator: electric replaces hydraulic

It used to be that when a machine designer was confronted with a high force linear actuator application, the only solution was a hydraulic cylinder. That meant the designer had to factor in the bulky hydraulic power unit (HPU), the inevitable leaks of hydraulic fluid and the downtime produced by frequent maintenance.

Now there’s another option when a high force linear actuator is needed. There are electric linear actuator products that can meet demanding specifications with ease.

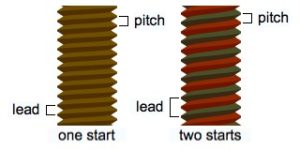

Electric linear actuator lead screws – article round-up

When it comes to specifying an electric linear actuator, selecting the right lead screw* (sometimes referred to as the leadscrew) for the application is critical. That’s because the screw is the major drive component in most electric actuators. After all, if it’s not a belt-driven actuator, then there’s a lead screw involved.

Ask an Engineer

Ask an Engineer