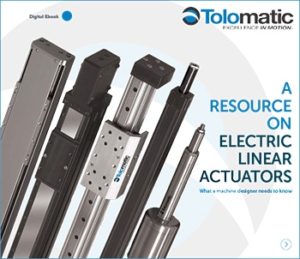

Maximize Your Uptime With Electric Linear Actuators

Maximize Your Uptime With Electric Linear Actuators To meet demand to minimize downtime in automation environments, many engineers are turning to electric linear actuators to design low-maintenance machines.

Five tips for designing electric actuators into food processing equipment

Machines used for food processing increasingly must be designed to meet ever-stringent requirements to keep food clean during production and ensure it arrives safely to the consumer. Hygienic actuators are a key ingredient to help maintain the highest standards for health and safety.

Design it yourself: 4 steps to actuator selection

Size and select your actuator with easy online tools.

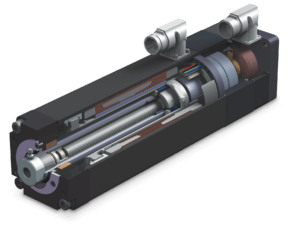

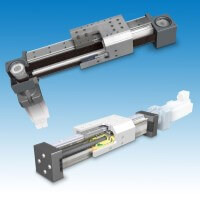

Small yet beefy

An internal servo motor makes for a smart, heavy duty and compact electric actuator package, one that is easy to retrofit or install new.

A pressing need

An electric servo-mechanical press offers all the versatility of a hydraulic press, with production speeds close to a flywheel press.

Gantry and multi-axis system: Build it your way

Gantries can be complicated and specialized. There are infinite variations for moving an object on multiple axes. But multi-axis motion control systems don’t have to be intimidating if you follow a straight-forward method that involves four steps.

Extend your reach

Actuators create the motion for collaborative robots and autonomous guided vehicles, whether it’s extending the reach of a robotic arm or steering a 40-foot shipping container.

Go electric!

So maybe you missed Bob Dylan’s infamous switch to electric at the Newport Folk Festival in 1965. These days, you, too, can go electric—with an electromechanical system instead of hydraulic. Our new e-book helps you overcome pre-conceived notions and provides tips for a successful performance.

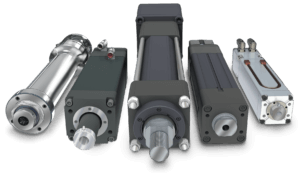

Machine builders: Have it your way

It’s usually straightforward to tweak a feature on a catalog product into something we call a modified standard product. Sometimes, you may need a highly customized solution for a specific application. That means starting with a blank sheet of paper. It all depends on your application and how the actuator is used in it.

How accurate is an actuator?

Accuracy and repeatability are two separate but related concepts of a linear motion system. The motor, drive and electric actuator itself all influence accuracy and repeatability. It’s quite possible you may need repeatability more than accuracy.

Fast and flexible: How to design a mask-making machine

Manufacturer rapidly invents a new way to make face masks in response to the COVID-19 pandemic. Electric actuators assist with linear motion technology.

The best things come in sturdy packages

Automatic packaging machines must efficiently and consistently form and assemble boxes of all shapes and sizes. Pneumatic cylinders have been a long-standing and economcial solution for box-forming machines. However, electric linear actuators provide controlled movement and reliability advantages while meeting the same motion and force requirements.

Traditional or integrated actuator? 10 factors to consider

Two common styles of electric rod actuators offer performance advantages depending on application and requirements. Knowing how to assess the differences and what to compare helps you meet your spec requirement.

Easy as pie

Five best practices for designing and installing electric actuators in food processing equipment help create open/clean-in-place designs.

Actuator know-how for machine design engineers, Part 2

Machine designers face a variety of options when selecting linear actuators. It all comes down the best fit for the application: what solution provides the best results at a cost– effective price.

Haunted house animatronics: Expect the unexpected…(cue the evil laugh)

What makes scary creatures scary? It’s not smoke and mirrors. It’s motion control.

Specifying actuators 101: Actuator know-how for machine design engineers, Part 1

Learn key tips to simply actuator selection, starting with the initial decision of whether to specify an electric rod actuator or a rodless electromechanical actuator. It's all covered in our eBook, a ready-reference for your next maachine design project.

Motion control keeps material handling systems moving

In these stay-at-home days, online shoppers increase the need for accurate, fast and efficient material handling systems, from processing paper products to packaging, conveying and shipping. Electric actuation is bringing many benefits to applications that have typically been pneumatic.

Linear actuators for gantry and multi-axis systems

Gantry and multi-axis systems are used throughout manufacturing to lift, position and move loads. Actuators and components are used to build two-dimensional designs with a simple XY axis, or three-dimensional designs with XYZ axis.

How electric actuators keep tire manufacturing up to speed

Motion control systems throughout the tire-manufacturing process meet specific requirements for increased quality, faster assembly, improved reliability or flexibility to adjust sizes and changeovers. Many systems are currently driven by pneumatic or hydraulic motion control systems. Manufacturers are increasingly opting for electric systems that are cleaner, faster and more efficient.

Making the case: Why convert a tube-bending machine from hydraulic to electric

Tube-bending machines have been driven by hydraulics for the past 80 years. Operators know how to get the best out of their machines, so why switch to electric cylinders? Yes, there are some disadvantages to going electric, but the fundamental reason to consider making the switch is simple: Electric cylinders make better parts. And that saves money. We'll discuss reasons to consider making the switch and take a look at two examples using electric-weld tubing and fluid-transfer tubing.

Demystifying electronic camming

Electronic cams may at first appear challenging, but electric actuators and motion controllers make them surprisingly easy to configure. Here’s how to approach electronic camming with confidence.

Cheese-making: Automating an ancient art for safety and efficiency

Electric linear motion enhances cheese processing and production.

Linear motion for meat processing

Linear actuators used in meat processing are designed for corrosion resistance, washdown protection and bacterial growth prevention.

Motion control solutions for medical device applications

Solutions for medical procedures include equipment for radiation treatment, a contrast dye injection, and a specialty machine that safely performs scans on large animals.

The Big Era of electromechanical linear actuators

Traditionally, hydraulic power is the go-to answer for heavy lifting. Now, high-force electric actuators have overtaken hydraulics in terms of flexibility, precision and reliability.

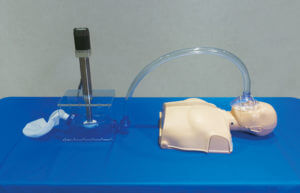

Automating the squeeze: Tolomatic prototype improves on hand-held emergency ventilator for COVID-19 patients

Our prototypes use electric linear actuators to automate a hand-held, portable and non-invasive emergency ventilator. The advantage of screw-driven linear actuators is that they provide smooth and consistent operation--allowing the device to control the velocity, the acceleration and the distance of any move at any point in time. This controlled motion allows for a more continuous volume of air per compression cycle and a more typical breathing cycle.

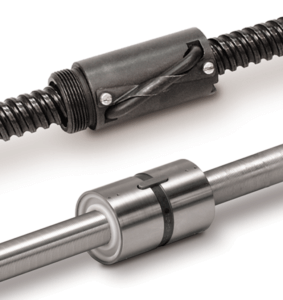

Timing belt or power screw drive: What’s best for a rodless actuator?

As a designer, you may be faced with an application in which you have to carry and support a load as well as move it. These are ideal applications for rodless electromechanical actuators.

While determining which rodless actuator model will suit your needs, you'll also need to select the type of drive: belt or screw. This blog will briefly explain these drive systems and summarize their advantages and disadvantages

Electric linear motion vs. pneumatic. 8 things every designer should know about selection

There’s a debate in the machine design community about what’s the best linear motion technology—electric or pneumatic. There are proponents on both sides. As a manufacturer of both electric and pneumatic linear actuators, we’d like to bring some balance to the discussion.

Electric linear motion has benefits as do pneumatic solutions. This blog will give you eight factors to consider when you’re making this important selection

What’s best? Integrated linear actuators or traditional.

When you’re faced with designing a new piece of automation equipment, you have a lot on your mind. Concerns like performance requirements. How to design flexibility into the machine. How to keep costs down. How to pack the performance needed into a compact package.

You can rely to electric linear actuators to address these issues. They have inherent flexibility and long-term cost-efficiency. Once you choose electric linear motion, you can select either an integrated linear actuator or a traditional design. Both options have pluses and minuses that we’ll review here.

Innovate with linear motion: Online resource for integrating electric actuators into machine designs

For every application a machine designer tackles, they have to consider a unique set of requirements. Evaluating a variety of linear motion attributes is key to determining the optimal solution.

Stop Motion or High Definition?

It was a rough week for the whole team working on a new customer’s new machine design. Finally, it’s Friday night and you sit down on the couch to relax with your friends. You made some popcorn and just popped in a DVD recommended by your parents. They told you it’s a classic and might be a bit slow but it has a good story. The movie starts and after 30 seconds, your friends are giving you confused looks. The movie is very difficult to watch because it is filmed in stop motion. The images on the screen are frozen and jump from one to the next. Sometimes it is half a second between shifts and sometimes it can be several seconds. You can see the evening disintegrating and quickly move to switch out the movie to ‘The Fast and the Furious’ for some non-stop action.

Failure not an option? How to avoid premature linear screw actuator failure

Some components are more mission-critical than others. A main worry of machine design engineers is making equipment that will last and avoiding need for field service calls to diagnose issues and replace failing components. At their core, electric linear screw actuators deploy mechanical technology such as ball bearings, ball screws and roller screws that have a finite life. These components do not last forever, even though that is the expectation of some customers. When asked “How long will this actuator last?” we provide our customers with a way to calculate, estimate and size the electric linear screw actuator to achieve the desired life for their applications.

Advantages of rodless electromechanical actuators

Many industrial applications call for linear actuators. After gathering the data, the designer faces a crucially important choice early on – whether an electric rod actuator or rodless electromechanical actuator is best. If a rodless actuator is the choice, there are several factors the designer considers in final selection.

Product modification. Get an actuator tailored to your project.

Sometimes the electric linear actuator an OEM machine designer needs is right there in the catalog. But other times nothing standard fills the bill. When a standard product meets 90% of your application’s needs, often product modification can get you the final 10%. To get to 100%, though, an OEM needs an experienced, innovative and knowledgeable linear actuator partner.

Why single-source your electric linear motion systems

The trend in industrial component sourcing is to eliminate waste, reduce costs and improve efficiency. This often means consolidating suppliers into single-source relationships. Single sourcing can build stronger relationships with suppliers, boost system performance and increase the speed of procurement.

Machine designers can use a single-source approach to reduce time spent on sourcing, installing and testing electric linear motion systems.

What to consider: electric actuators for food and beverage processing

Keeping things clean is a top concern in food and beverage processing operations because food safety is crucial. The Food Safety Modernization Act (FSMA), with its emphasis on preventing foodborne illness, puts even more pressure on food producers. Machine designers who serve this industry need to incorporate components that meet the industry’s demands. When it comes to electric linear actuators, there are several things a design engineer needs to consider, especially if the machine will be subjected to periodic washdowns.

Electric linear motion. Selecting linear actuators.

Linear actuators are familiar components in many factory automation systems. They’re one of the usual suspects in any line-up of linear motion components.

There’s a lot riding on specifying the right linear actuator for the task. Choose well and it’s smooth sailing. The actuator performs without a glitch for a long time. Choose the wrong one, and it’s a bumpy ride. You can wind up with break-downs and poor product quality.

Selection tips: rodless electromechanical & electric rod actuators

When you specify a linear actuator, some basic decisions come first. Like electric or fluid-powered?Like do you need the push/pull of an electric rod actuator or the load-carrying action of a rodless electromechanical actuator?

We’ve compiled tips for selecting these actuator types. Here’s an opportunity to increase your knowledge of electric linear motion.

The great debate: Electric linear actuators vs. pneumatic

There’s a new debate in motion among machine designers. What’s best? Pneumatic or electric linear actuators? The truth is it depends on the application. What follows is an honest comparison of linear actuator choices – an assessment of strengths and weaknesses – so you can choose what’s best for your project.

Test your motion control smarts. Take the electric linear actuator quiz.

Linear actuators are common and critical elements in many industrial machines and automation systems. With so many choices on the market, it’s important to know how to select the best one for your application.

You probably know a lot about linear actuators. But do you know everything? Our electric linear actuator quiz will test your engineering smarts.

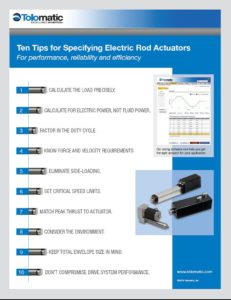

10 tips for specifying electric rod actuators: Part 2

In many applications electric rod actuators are a great solution. Compared to pneumatic or hydraulic cylinders, electric linear actuators offer more control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often the superior actuation choice.

10 tips for specifying electric rod actuators: Part 1

There are lots of good reasons for specifying an electric rod actuator. Electric linear actuators offer a high degree of control over application parameters like position, velocity, and force. They deliver high degrees of accuracy and repeatability and can handle complex motion profiles. All things considered, an electric rod actuator is often a superior actuation choice compared to pneumatic or hydraulic cylinders.

How to select electric linear actuators that stand the test of time

The length of time a linear actuator will function (i.e., service life) is critically important to a machine designer. Machines need to keep working reliably with little or no need for lengthy maintenance that will take a machine off-line . So, components like actuators must keep working.

Go long! Selecting a long stroke electric linear actuator

Some linear actuator application requirements mean you have to go long. Long stroke, that is. Length of stroke is a critical factor in electric linear actuator selection. While some applications require moves of just inches or a few feet, others require moves of 10 feet or more. For an application requiring this kind of long stroke linear actuator, a belt driven rodless electromechanical actuator will be your solution.

Ask an Engineer

Ask an Engineer