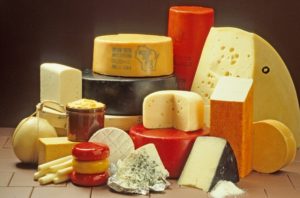

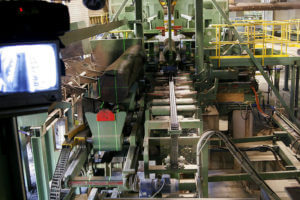

Cheese-making: Automating an ancient art for safety and efficiency

Electric linear motion enhances cheese processing and production.

Linear motion for meat processing

Linear actuators used in meat processing are designed for corrosion resistance, washdown protection and bacterial growth prevention.

Stainless steel linear actuators stand up to corrosion, tough conditions

Machine designers who develop systems for harsh environments often need corrosion resistant components, including stainless steel linear actuators, to stand up to challenging environmental conditions. Corrosive agents, moisture and dust in manufacturing environments impact the performance and life of automationn components. Dust and debris may enter housings causing wear. Moisture may short electrical connections. Corrosive agents can eat away at housings, seals, fasteners and more. For confirmation that a component will stand up to environmental factors, we recommend the IP (International Protection or Ingress Protection) rating system.

How to specify an electric linear actuator that’s industrial strength

Manufacturing environments can be challenging. There may be dust or metal shavings. There may be oil, coolant, or water. There may be corrosive agents like solvents, cleaners, and various chemicals and compounds.

All these factors impact the performance and life of components like electric linear actuators. Dust may clog the action or cause parts to wear out prematurely. Moisture may short electrical connections and cause rusting. Corrosive agents can eat away at housings, seals, fasteners, and more. Industrial environments call for industrial strength components.

A machine designer needs confirmation that a component will stand up to environmental factors.

Electric linear actuator stands up to moisture, dust

Linear actuators used in sawmills are often subjected to dusty and wet conditions. If the right electric linear actuator isn’t specified, the component may fail and cause expensive downtime. Given the pressure to keep production costs down and output up, it’s essential to match the actuator to the manufacturing environment.

A good way to do this is to refer to a rating system. We use the IP (Ingress or International Protection) system because it evaluates ingress of both dry particles and moisture. An application where there is both dust and water spray needs electric linear actuators rated IP67 for a high degree of protection.

Electric linear actuator selection tips: Consider the environment

When you’re faced with electric linear actuator selection, one of the early considerations has to be the industrial environment in which it will operate. Will there be dust? How much dust and what kind? Will there be moisture? Direct spray? High temperatures and pressures? Corrosive substances?

These factors affect the performance of an electric linear actuator and may point to the best type for an application.

Ask an Engineer

Ask an Engineer