Solving Harsh Environment Challenges for Linear Motion

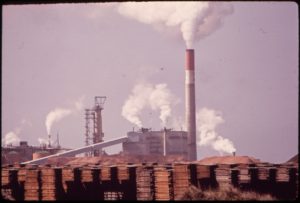

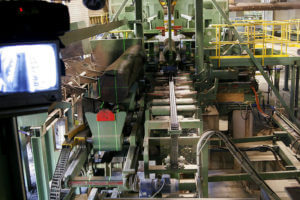

Electric linear actuators deliver excellent performance in extreme environmental challenges like those found in lumber processing, mining and other applications.

Electric Actuators Help You Keep Up With the NFPA Technology Roadmap

A recent National Fluid Power Association (NFPA) survey illuminated technology objectives that enable machine builders and OEMs to stay competitive in their industries. The most important objectives that emerged from the survey included: ● Increased availability and uptime ● Increased productivity and performance ● Regulation compliance ● Lower total cost of ownership

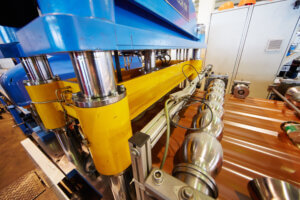

How Electric Actuators Optimize Pressing Applications

It’s common for presses to feature hydraulic or pneumatic cylinders, but using electric actuators can optimize many press designs. Linear servo presses, which rely on electric actuation, eliminate noisy and leaking hydraulic and pneumatic components.

A pressing need

An electric servo-mechanical press offers all the versatility of a hydraulic press, with production speeds close to a flywheel press.

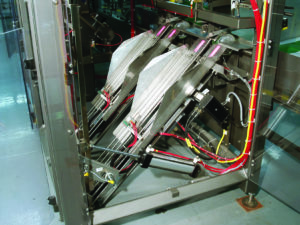

In the bag

Rodless electro-mechanical actuators on a modular bagging system precisely position incoming bags regardless of size.

Gantry and multi-axis system: Build it your way

Gantries can be complicated and specialized. There are infinite variations for moving an object on multiple axes. But multi-axis motion control systems don’t have to be intimidating if you follow a straight-forward method that involves four steps.

Extend your reach

Actuators create the motion for collaborative robots and autonomous guided vehicles, whether it’s extending the reach of a robotic arm or steering a 40-foot shipping container.

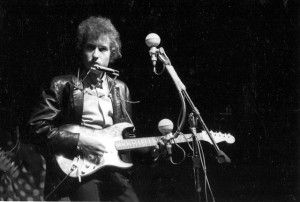

Go electric!

So maybe you missed Bob Dylan’s infamous switch to electric at the Newport Folk Festival in 1965. These days, you, too, can go electric—with an electromechanical system instead of hydraulic. Our new e-book helps you overcome pre-conceived notions and provides tips for a successful performance.

Machine builders: Have it your way

It’s usually straightforward to tweak a feature on a catalog product into something we call a modified standard product. Sometimes, you may need a highly customized solution for a specific application. That means starting with a blank sheet of paper. It all depends on your application and how the actuator is used in it.

The best things come in sturdy packages

Automatic packaging machines must efficiently and consistently form and assemble boxes of all shapes and sizes. Pneumatic cylinders have been a long-standing and economcial solution for box-forming machines. However, electric linear actuators provide controlled movement and reliability advantages while meeting the same motion and force requirements.

Haunted house animatronics: Expect the unexpected…(cue the evil laugh)

What makes scary creatures scary? It’s not smoke and mirrors. It’s motion control.

Specifying actuators 101: Actuator know-how for machine design engineers, Part 1

Learn key tips to simply actuator selection, starting with the initial decision of whether to specify an electric rod actuator or a rodless electromechanical actuator. It's all covered in our eBook, a ready-reference for your next maachine design project.

Motion control keeps material handling systems moving

In these stay-at-home days, online shoppers increase the need for accurate, fast and efficient material handling systems, from processing paper products to packaging, conveying and shipping. Electric actuation is bringing many benefits to applications that have typically been pneumatic.

Linear actuators for gantry and multi-axis systems

Gantry and multi-axis systems are used throughout manufacturing to lift, position and move loads. Actuators and components are used to build two-dimensional designs with a simple XY axis, or three-dimensional designs with XYZ axis.

How electric actuators keep tire manufacturing up to speed

Motion control systems throughout the tire-manufacturing process meet specific requirements for increased quality, faster assembly, improved reliability or flexibility to adjust sizes and changeovers. Many systems are currently driven by pneumatic or hydraulic motion control systems. Manufacturers are increasingly opting for electric systems that are cleaner, faster and more efficient.

Making the case: Why convert a tube-bending machine from hydraulic to electric

Tube-bending machines have been driven by hydraulics for the past 80 years. Operators know how to get the best out of their machines, so why switch to electric cylinders? Yes, there are some disadvantages to going electric, but the fundamental reason to consider making the switch is simple: Electric cylinders make better parts. And that saves money. We'll discuss reasons to consider making the switch and take a look at two examples using electric-weld tubing and fluid-transfer tubing.

Demystifying electronic camming

Electronic cams may at first appear challenging, but electric actuators and motion controllers make them surprisingly easy to configure. Here’s how to approach electronic camming with confidence.

Cheese-making: Automating an ancient art for safety and efficiency

Electric linear motion enhances cheese processing and production.

Motion control solutions for medical device applications

Solutions for medical procedures include equipment for radiation treatment, a contrast dye injection, and a specialty machine that safely performs scans on large animals.

High-force linear actuator makes muscle car simulation possible

Tolomatic linear actuators are used worldwide in a myriad of industries for automation tasks like conveying, sorting, filling and more. Beyond conventional industrial applications they are also used in demanding, non-industrial applications. Some of these, such as simulators for flight, driving, testing and entertainment, require high-frequency moves to create a realistic experience. Here’s one such story, in which our electric high-force linear actuators helped simulate the experience of popping a wheelie in a true muscle car.

Innovate with linear motion: Online resource for integrating electric actuators into machine designs

For every application a machine designer tackles, they have to consider a unique set of requirements. Evaluating a variety of linear motion attributes is key to determining the optimal solution.

Integrated servo motor simplifies sourcing electric linear motion

An OEM’s component sourcing strategy will impact the final cost of a piece of automation equipment. While it can seem best to source parts from multiple suppliers, the time and cost involved in sourcing and integrating parts can raise the total machine cost significantly. Using a single-source approach and integrated components, like an integrated servo motor and controller for an electric linear motion system, can save time and money in the long run.

Electric high-force linear actuators keep medical manufacturing clean

Machine designers know that hydraulic cylinders offer compact size and excellent power density. Designers also know there are serious drawbacks that make these cylinders problematic in many applications – problems such as inevitable leaks. Those leaks can be a significant hazard in manufacturing environments that demand cleanliness such as medical equipment production. It used to be that hydraulic cylinders were the only choice when a designer needed a high-force linear actuator. Now there are electric high-force linear actuators that can replace hydraulics in many applications, offering clean operation as well as better accuracy and control.

How to convert high-force linear actuators from hydraulic to electric

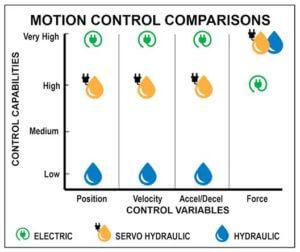

Things are changing in industrial automation. Many linear motion applications are getting more sophisticated with increased demand for control of process variables like velocity, thrust, acceleration/ deceleration and more.

It’s common for new applications that require high thrust from a linear actuator to use electric motion systems. Moreover, machine designers are converting existing hydraulic motion systems to electric.

High force linear actuators: how to convert from hydraulic to electric

Electric linear actuators have come a long way – especially in the area of high force. Once upon a time when an application required high force, the usual linear motion solution was a hydraulic cylinder. However, as industrial automation gets more sophisticated and the need for precise control of speed, force and other variables grows, more engineers are considering electric high force linear actuators.

Integrated servo motor and controller ensures actuator precision, versatility

Powder-filling applications require precision and versatility. Precision to fill containers to the exact weight or volume. Versatility to accommodate changes.

Machine designers depend on electric linear actuators to deliver precision and versatility. And they’re finding that an integrated servo motor and controller coupled with a reliable electric actuator can do just that.

Electric cylinder helps advance physical therapy

You may think linear actuators are strictly industrial components. Time to think again. We provide electric linear actuators for an innovative piece of medical equipment – the VibeTech Rehabilitation Chair used in physical therapy.

Hush! Minimizing noise in electric linear motion systems

Under most circumstances electric linear motion systems are quiet. They certainly don’t create the hissing and bang-bang noises associated with pneumatic systems. However, there’s another type of noise that comes with electric systems of all types – electrical noise or interference.

This is a common occurrence caused by random fluctuations in electrical signals. If the amplitude gets high enough, electrical noise can disrupt the operation of devices like electric linear actuators. The results can be anything from erratic movements to complete system failure.

Electric high speed linear actuator reduces conveyor’s TCO

Higher production speeds usually translate into higher output volumes – a good thing in manufacturing. At least it’s good if product quality stays high and operating costs remain in line. Machine designers are on the look-out for high speed linear actuators and other devices that can streamline processes. But those high-speed solutions need to be reasonably priced and efficient to use.

Electric rod actuators add accuracy and repeatability to PCB manufacturing

Some manufacturing processes require high precision -- printed circuit boards (PCB) production, for example. In these instances, the capabilities of each component in a production system are critical. Although machine designers know pneumatic cylinders well, these cylinders struggle to deliver the accuracy and repeatability demanded by high precision processes. Many design engineers now turn to electric rod actuators for accuracy and repeatability and for better operating efficiency.

Electric cylinders essential to advanced conveyor system [Case Study]

Conveying systems are common in manufacturing. They can be straight-forward systems that take packages from point A to point B or complex ones for sorting and diverting. Systems used in food processing also must handle washdowns, a common practice in the industry.

As critical components, linear actuators must withstand the challenges of the application including environmental ones. Pneumatic cylinders have been used extensively in conveying. However, electric cylinder use is growing, fueled by demand for programmability and better accuracy.

Electric rod actuator cleans up after hydraulics

Hydraulic cylinders are well-known linear motion workhorses in industrial machinery. They’re reliable, familiar, capable of high force, and affordable, but they’re not without disadvantages. The leading ones are fluid leaks, large footprint (with hydraulic power unit or HPU), cumbersome changeovers due to lack of programmability, and high maintenance costs.

The introduction of electric high force linear actuators means machine designers now have a choice. An electric rod actuator can replace a hydraulic cylinder and eliminate the need to clean up leaks.

Solid-bearing, belt-driven linear actuator handles harsh environment

Many applications call for the carrying action of a rodless electromechanical actuator. And many of these need the high speed and long stroke capabilities of a belt-driven linear actuator. But what do you do when your application is in a dusty, harsh environment? Many rodless electromechanical actuators can’t handle these conditions. Their roller bearings get clogged with dust and stop working. Could a solid bearing be the solution?

Hygienic linear actuator keeps it clean

The world of food production and packaging is broad, varied and ever-changing. That world needs filling machines as diverse as the range of food products they process. Some filling machines have to handle powders and dry solids while others must handle thin or thick liquids. Some machines fill to a specified level, and some fill by volume or weight. This wide variety of equipment has a unifying need, though -- a need for hygienic design that can keep food products uncontaminated and withstand even the most stringent cleaning procedures.

Electric linear actuator fills accuracy need under harsh conditions

Volumetric filling applications of any type require high levels of accuracy and repeatability. If the filling operation is part of a food and beverage processing plant, there are additional important factors. Factors like food safety and the ability to withstand even caustic washdowns.

Filling equipment designers often rely on electric linear actuators for crucial motion control. Like the machines they’re a part of, these electric actuators need to deliver accuracy and repeatability and may need to stand up to a challenging industrial environment.

Electric linear actuator stands up to moisture, dust

Linear actuators used in sawmills are often subjected to dusty and wet conditions. If the right electric linear actuator isn’t specified, the component may fail and cause expensive downtime. Given the pressure to keep production costs down and output up, it’s essential to match the actuator to the manufacturing environment.

A good way to do this is to refer to a rating system. We use the IP (Ingress or International Protection) system because it evaluates ingress of both dry particles and moisture. An application where there is both dust and water spray needs electric linear actuators rated IP67 for a high degree of protection.

Integrated linear actuator increases manufacturing efficiency

Production cost and efficiency are important considerations in all manufacturing, but these factors take on critical status in some segments. Small-engine production is one of these. Using the right linear actuator can boost efficiency and reduce cost.

Electric cylinders lower cost of conveying equipment

Conveying equipment manufacturers know that fast and efficient systems are critical to manufacturing success. Conveying system buyers are demanding better positioning accuracy, energy efficiency, and lower cost of ownership to ensure their ongoing success. Plus, some are eliminating compressed air systems and asking for electric linear actuators, including electric cylinders, instead of pneumatic solutions. Since they often produce several product models in the same plant, buyers need actuators that are easily programmable to several positioning set-ups.

Hygienic, IP69K electric rod actuator meets food processing needs

Food processing is a tough environment for most automation equipment. There may be washdowns with high-pressure, high-temperature water. Caustic cleaning agents might be used. There also may be strict food safety standards to adhere to, like the USDA’s regulations for the meat, poultry and dairy industries. As automation components, all linear actuators, like electric rod actuators, need to stand up to the rigors of the food processing environment.

Electric linear actuators deliver precise positioning for aerospace welding

Precision is integral to the aerospace and defense industries. Even a seemingly insignificant element of a device may be mission-critical, requiring the tightest manufacturing tolerances. That’s why when a rocket manufacturer contacted us about electric linear actuators that could hold their fuselage components in place for welding, we knew precise positioning would be a requirement.

Compact, integrated linear actuator helps the show go on

Ever have an application where you had space for a pneumatic cylinder but needed the precision, programmability, and low maintenance of an electric linear actuator? You needed a compact, precise, reliable linear actuator. Does such a product exist? Of course it does! Here's a case study about an application where an integrated actuator solved this problem.

Electrical noise and linear actuators

Electrical noise is a common occurrence. Random fluctuations in electrical signals are known as noise, and if the amplitude of the fluctuations becomes high enough, the noise can interfere dramatically with the operation of industrial automation devices like linear actuators. The results can be anything from erratic movements to complete system failure.

Something completely different – unique electric linear actuator applications

We all recognize that linear actuators are critical and much-used components in industrial automation systems. They’re at the heart of many machine tools, conveying configurations, and packaging systems. But what if we look beyond those industrial uses? Here are a few unique applications our actuators have found themselves in.

How electric linear actuators improve automation results

The industrial revolution continues to rock the world as improvements in factory automation create ongoing change. The goal of saving money while improving quality is at the core of the drive towards more sophisticated automation. Savings come from reduced labor costs, higher throughput, lower energy use, or reduced waste. Better quality is a by-product of controlling variables within tight tolerances.

Ask an Engineer

Ask an Engineer