Compact, integrated linear actuator helps the show go on

By Tolomatic on June 16, 2015

Ever have an application where you had space for a pneumatic cylinder but needed the precision, programmability, and low maintenance of an electric linear actuator? You needed a compact, precise, reliable linear actuator. Does such a product exist? Of course it does! Here’s a case study about an application where an integrated linear actuator solved this problem.

Ever have an application where you had space for a pneumatic cylinder but needed the precision, programmability, and low maintenance of an electric linear actuator? You needed a compact, precise, reliable linear actuator. Does such a product exist? Of course it does! Here’s a case study about an application where an integrated linear actuator solved this problem.

To learn more, download our white paper on traditional versus integrated rod-style actuators.

Application calls for reliability, precision, small footprint

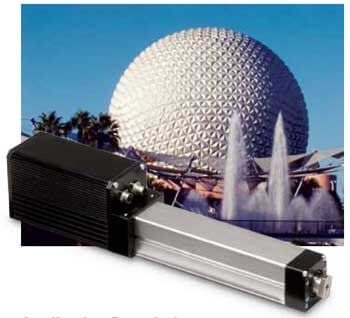

In the entertainment industry, timing can be essential to the effect of a presentation. That was certainly the case when designers from a major amusement park asked us to consult on the selection of a linear motion device for a new attraction.

The designers needed to move a heavy camera to a precise position. Reliable operation was essential, and space was at a premium. The first priority was to give the attraction’s visitors enough room to fully appreciate the effect, so the motion control system needed to have as small a footprint as possible. Finally, the system had to have little to no downtime for repairs and maintenance. (Downtime would mean lost revenue.)

Pneumatic and electric linear actuators considered

The attraction designers considered two traditional linear motion solutions – pneumatic and electric actuator systems. A pneumatic cylinder would have been a simple, low-cost solution…and one that could fit the available space. However, pneumatic models couldn’t deliver the precise positioning needed and required too-frequent maintenance and replacement. Also, there was no existing compressed air system to power the cylinder.

Traditional electric actuators could answer the precision and reliability requirements; however, the systems involved many components – actuator, motor, driver, controller, cables, and wiring. All this would take up space, detracting from the visitor’s experience. Plus having to specify and configure all the components seemed a daunting, time-consuming task for the over-taxed designers.

Integrated actuator fills the bill

The designers were stumped until we suggested another option – an integrated actuator. This product combines a linear actuator, motor, and controller in one device. Integrated actuators deliver the reliability and precision of traditional electric linear actuator systems. In addition, they take up much less space, in many cases being able to fit the same footprint as a pneumatic cylinder.

Our ICR20 SmartActuator®, an integrated, intelligent actuator, was chosen for its compact size and low-maintenance design. Implementation was simple with easy-to-use software. The ICR was able to position the camera precisely every time. The attraction designers were pleased to find a solution that met all their requirements:

- All-in-one, space-saving solution

- No maintenance

- Precise positioning time after time

- Easy installation

ICR SmartActuator

The ICR SmartActuator is an integrated package that combines an electric rod actuator, servo motor, and controller into a compact system. The ICR has a stroke length of 24 inches, handles 100% duty cycle applications, is available in two ball screw configurations, and offers an IP65 option.

There are two ICR models:

- ICR SmartActuator BASIC for simple extend and retract operation.

- ICR SmartActuator PLUS with indexer programming and network communication capabilities.

Either can be ordered as an inline motor or reverse parallel configuration.

Learn more

Want to know more about the ICR SmartActuator? Download our brochure, or click here for our white paper on traditional versus integrated rod-style actuators.

Ask an Engineer

Ask an Engineer