Electric linear actuator accuracy and repeatability webinar

By Gary Rosengren on September 20, 2016

When an engineer is developing a machine design, accuracy is often top-of-mind. So is machine cost. But these two considerations can be at odds since the usual scenario is that the higher the accuracy of a device, the higher the cost. This certainly holds true for electric linear actuators and linear motion systems.

When an engineer is developing a machine design, accuracy is often top-of-mind. So is machine cost. But these two considerations can be at odds since the usual scenario is that the higher the accuracy of a device, the higher the cost. This certainly holds true for electric linear actuators and linear motion systems.

Engineers often ask us about the accuracy of our different products. They’d like a simple answer, but there really isn’t one. Accuracy is dependent on many factors, so you have to look at the application itself to know how an actuator will perform.

Don’t throw your hands up in frustration, though. Talk to Tolomatic first when your design calls for linear motion. It might be that what your application really needs is repeatability rather than accuracy. Or you may be able to adjust mounting and other parameters so you can use a lower cost actuator.

Or view our webinar.

Definitions

Here are two definitions you need to know.

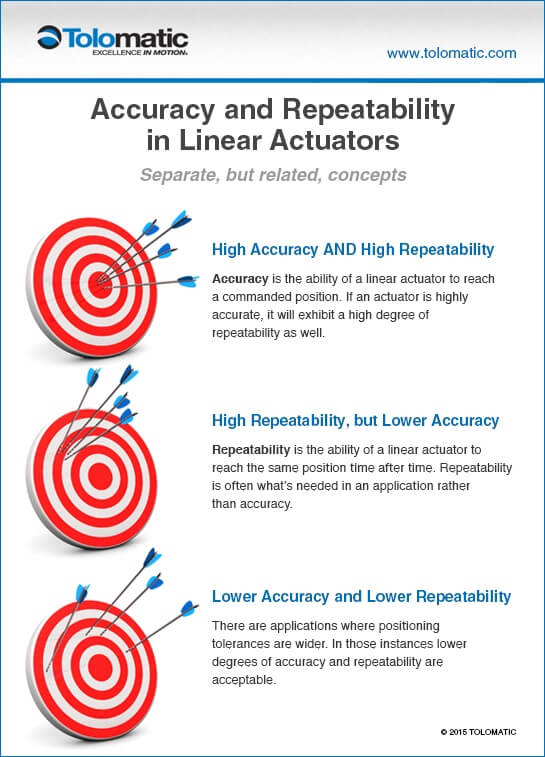

- Accuracy means hitting the bullseye every time. In linear actuator terms that means consistently reaching an assigned position.

- Repeatability means reaching the same position time after time. That position may or may not be the assigned position. So you may not be hitting the bullseye but you’re hitting the same point on the target every time.

Match the actuator to the application

As we mentioned above, accuracy is affected by many factors. Along with the potential for inaccuracy in the motor, controller, and encoder, every  electric linear motion system has the potential for position errors around the X, Y and Z axes of the actuator itself. Back and forth. Side to side. Up and down. Linear actuators are mechanical devices with built-in tolerances along these planes and, of course, there’s rotation around each axis to keep in mind.

electric linear motion system has the potential for position errors around the X, Y and Z axes of the actuator itself. Back and forth. Side to side. Up and down. Linear actuators are mechanical devices with built-in tolerances along these planes and, of course, there’s rotation around each axis to keep in mind.

Let’s consider the housing of an actuator. Maybe the housing allows some bow and twist which would lead to position errors on the X and Y axes. This might make the actuator inappropriate for some high-precision applications and cause a machine designer to look at more accurate alternatives.

That same actuator could perform very well in another application, though. Consider an application where the actuator can be secured to a known flat surface. That would eliminate the bow and twist problems, allowing the machine designer to use a lower cost actuator that’s theoretically less accurate but repeatable and performs well in practice.

Learn more

Download our white paper: Introduction to accuracy and repeatability in linear motion systems.

Ask an Engineer

Ask an Engineer