How to convert high-force linear actuators from hydraulic to electric

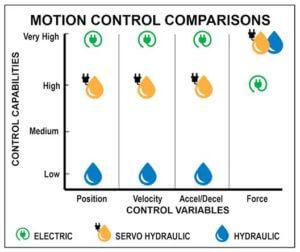

Things are changing in industrial automation. Many linear motion applications are getting more sophisticated with increased demand for control of process variables like velocity, thrust, acceleration/ deceleration and more.

It’s common for new applications that require high thrust from a linear actuator to use electric motion systems. Moreover, machine designers are converting existing hydraulic motion systems to electric.

High force linear actuators: how to convert from hydraulic to electric

Electric linear actuators have come a long way – especially in the area of high force. Once upon a time when an application required high force, the usual linear motion solution was a hydraulic cylinder. However, as industrial automation gets more sophisticated and the need for precise control of speed, force and other variables grows, more engineers are considering electric high force linear actuators.

Advantages of rodless electromechanical actuators

Many industrial applications call for linear actuators. After gathering the data, the designer faces a crucially important choice early on – whether an electric rod actuator or rodless electromechanical actuator is best. If a rodless actuator is the choice, there are several factors the designer considers in final selection.

Electric cylinders speed up food processing operation

From food processing plants to machine shops, there’s a constant drive for greater efficiency, faster turnaround and less downtime. Everyone is involved in the effort, from design engineers who develop equipment to plant engineers who manage processes. In food processing operations, the need for speed translates into things like faster operation, easier cleaning, greater accuracy and less maintenance. Electric linear actuators and electric cylinders used in these plants need to meet specific standards.

Changeover is faster with electric high-force linear actuators.

There’s no denying that hydraulic cylinders can provide reliable linear motion in the right applications. However, hydraulics cylinders often leak, and can be difficult to control. When a changeover is needed, adjusting a hydraulic cylinder is a time-consuming, hit-and-miss process. New electric high-force linear actuators are an alternative to hydraulics in many applications.

Product modification. Get an actuator tailored to your project.

Sometimes the electric linear actuator an OEM machine designer needs is right there in the catalog. But other times nothing standard fills the bill. When a standard product meets 90% of your application’s needs, often product modification can get you the final 10%. To get to 100%, though, an OEM needs an experienced, innovative and knowledgeable linear actuator partner.

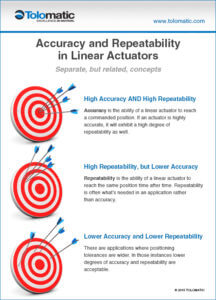

Accuracy and repeatability. Only pay for what you need.

When a machine’s design calls for an electric linear actuator, most design engineers want to know about an actuator’s accuracy and repeatability…with emphasis on accuracy.

Electric high-force linear actuator choices. Ball vs roller screw

Many applications require high-force linear actuators – from moving equipment in a foundry to powering a press in metal forming to guiding heavy logs in a sawmill. Whatever the application, a machine designer is faced with a choice…whether to specify a ball or roller screw in the electric high-force linear actuator.

Integrated servo motor and controller ensures actuator precision, versatility

Powder-filling applications require precision and versatility. Precision to fill containers to the exact weight or volume. Versatility to accommodate changes.

Machine designers depend on electric linear actuators to deliver precision and versatility. And they’re finding that an integrated servo motor and controller coupled with a reliable electric actuator can do just that.

Electric cylinder helps advance physical therapy

You may think linear actuators are strictly industrial components. Time to think again. We provide electric linear actuators for an innovative piece of medical equipment – the VibeTech Rehabilitation Chair used in physical therapy.

Ask an Engineer

Ask an Engineer