Rodless electromechanical linear actuator selection: A webinar

By Tolomatic on February 23, 2016

Rodless or rod-style linear actuator? It’s a basic and critical decision point for any machine designer. Consider the specifics of your application. Either actuator type has advantages and disadvantages. In general, if a load needs to be pushed or pulled, select an electric rod actuator. However, if you need an actuator to carry a load, a rodless product is what you need. Want to reduce the complexity of a linear motion system? A rodless electromechanical linear actuator can eliminate the need for load-bearing and guiding elements. Also, a rodless actuator can reduce the footprint of a system since its stroke lies completely within its body.

Rodless or rod-style linear actuator? It’s a basic and critical decision point for any machine designer. Consider the specifics of your application. Either actuator type has advantages and disadvantages. In general, if a load needs to be pushed or pulled, select an electric rod actuator. However, if you need an actuator to carry a load, a rodless product is what you need. Want to reduce the complexity of a linear motion system? A rodless electromechanical linear actuator can eliminate the need for load-bearing and guiding elements. Also, a rodless actuator can reduce the footprint of a system since its stroke lies completely within its body.

Once you’ve decided on a rodless linear actuator, you’ll need to consider several factors to ensure you select the best model for your application. Our webinar offers an excellent review of these factors.

Rodless electromechanical linear actuators: What to consider

Selecting the best rodless electromechanical linear actuator for an application takes careful thought and calculation in order to get maximum  reliability and efficiency from the device. Here are our ten tips to help you when you’re specifying electric rodless linear actuators:

reliability and efficiency from the device. Here are our ten tips to help you when you’re specifying electric rodless linear actuators:

TIP #1 Calculate all loads precisely.

Knowing the static and dynamic loads involved in the application lets you select the appropriate motor, screw, belt, and other components. That means knowing loads for all three axes (X, Y, and Z.) Matching the peak and continuous load capabilities of the actuator to the application’s actual loads will give you a system that works efficiently over the long haul.

TIP #2 Don’t over-size.

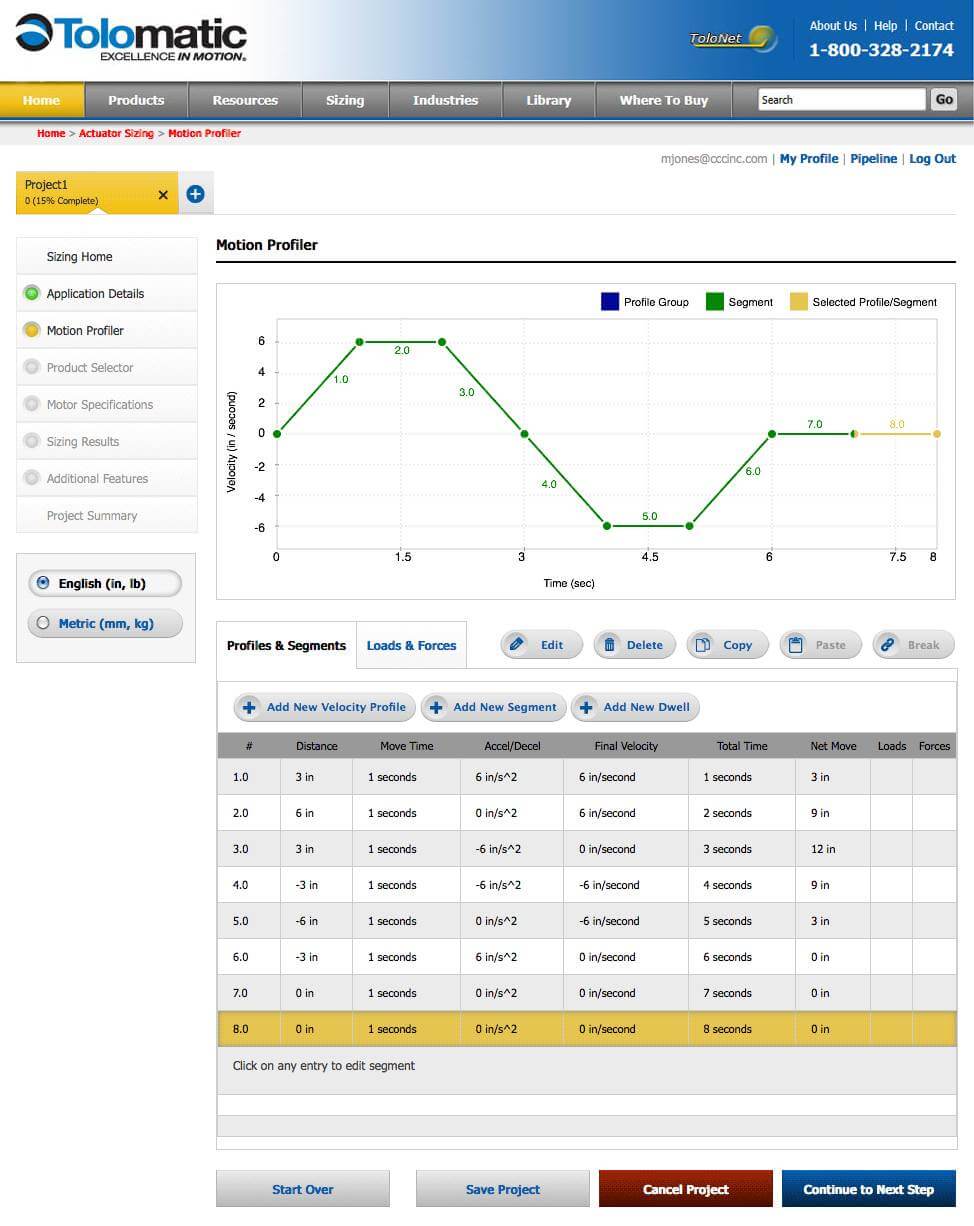

For pneumatic cylinders, over-sizing by up to two times has been a common practice. It’s an insurance policy in a way…a hedge against engineering uncertainty. However, over-sizing an electric linear actuator can get very expensive. Cover all bases, then rely on sizing software to get the right linear actuator for the application.

For pneumatic cylinders, over-sizing by up to two times has been a common practice. It’s an insurance policy in a way…a hedge against engineering uncertainty. However, over-sizing an electric linear actuator can get very expensive. Cover all bases, then rely on sizing software to get the right linear actuator for the application.

TIP #3 Calculate moments (torques).

Think about all three axes. Since rodless actuators carry loads, there will be stresses on the bearing system for the actuator’s load-carrying platform. You can only specify the right actuator for an application if you’ve calculated roll, yaw, and pitch.

TIP #4 Consider the effects of speed and inertia.

If you ignore speed limits with a screw-driven actuator, you may have to deal with noise, vibration and even failure resulting from screw-whip. With belt-driven models, you may find heavy loads difficult to start or stop if the actuator can’t handle the weight and inertial forces.

TIP #5 Factor in the duty cycle.

What’s duty cycle, you ask? It’s the ratio or percentage of operating time to total cycle time. (If an actuator operates for 2 seconds and rests for 2, then the cycle time is 4 seconds, and the duty cycle is 2/4 or 50%.) With electric linear actuators, underestimating the duty cycle can lead to overheating, wear and premature failure. Overestimating can lead to costly over-sizing.

TIP #6 Mounting makes a difference.

Mounting is especially critical if you need a long-stroke rodless actuator. Make sure you factor in enough support points to ensure rigidity. Also, the mounting surface has to be straight and flat, and there needs to be enough space for the actuator and motor combination.

TIP #7 Consider both the configuration and power output of the drive system.

A reverse parallel motor can appear to be a good choice because it reduces the footprint of a linear motion system. However, motors mounted this way can be less efficient because of the gear or belt reduction drives required. If your application needs the power output of an in-line motor, make room for it or your system will underperform and maybe even fail.

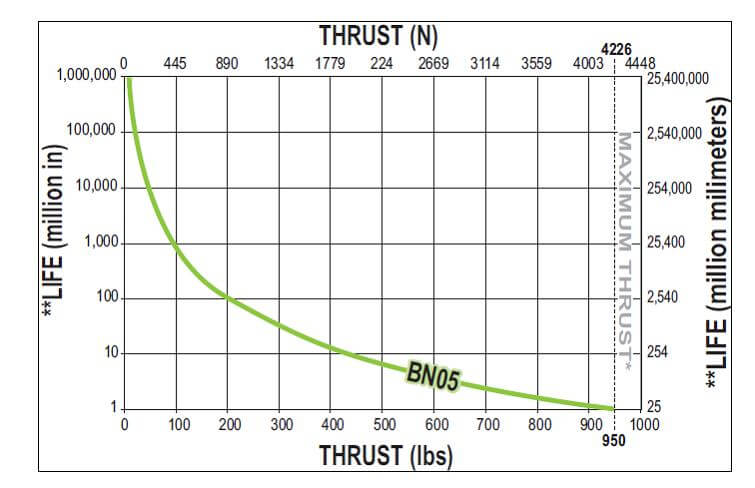

TIP #8 Match life expectations with actuator capabilities.

A rodless electric actuator will not last long if its drive (screw or belt) or carrier bearing system is over-stressed by the load the actuator carries and the speed at which it operates. Specify an actuator that’s suited to the task or be prepared to replace it early and often.

TIP #9 Be certain about accuracy requirements

Understanding your application’s requirements for accuracy will let you specify the best rodless actuator. Screw type has a significant impact on the accuracy of screw actuators. Belt drive actuators have limitations when it comes to accuracy due to manufacturing limitations and the fact that belts stretch over time.

TIP #10 Factor in the environment

Temperature extremes (cold or hot) will affect the performance of linear actuator components. Contaminants like oil, dust, grit, water and cleaning solutions can impact performance and service life.

Ask an Engineer

Ask an Engineer