Unleashing the Capabilities of the Linear Servo Press in Manufacturing

This whitepaper explores how linear and mechanical servo press technologies compare with hydraulic presses and the key design considerations.

Webinar On Demand

Unleashing Linear Servo Press Technology

An overview of press technologies & considerations for linear servo presses in the manufacturing environment.

Discover how servo-electric press technologies offer significant advantages in precision, programmability, energy efficiency, reliability, and flexibility compared to hydraulic machines.

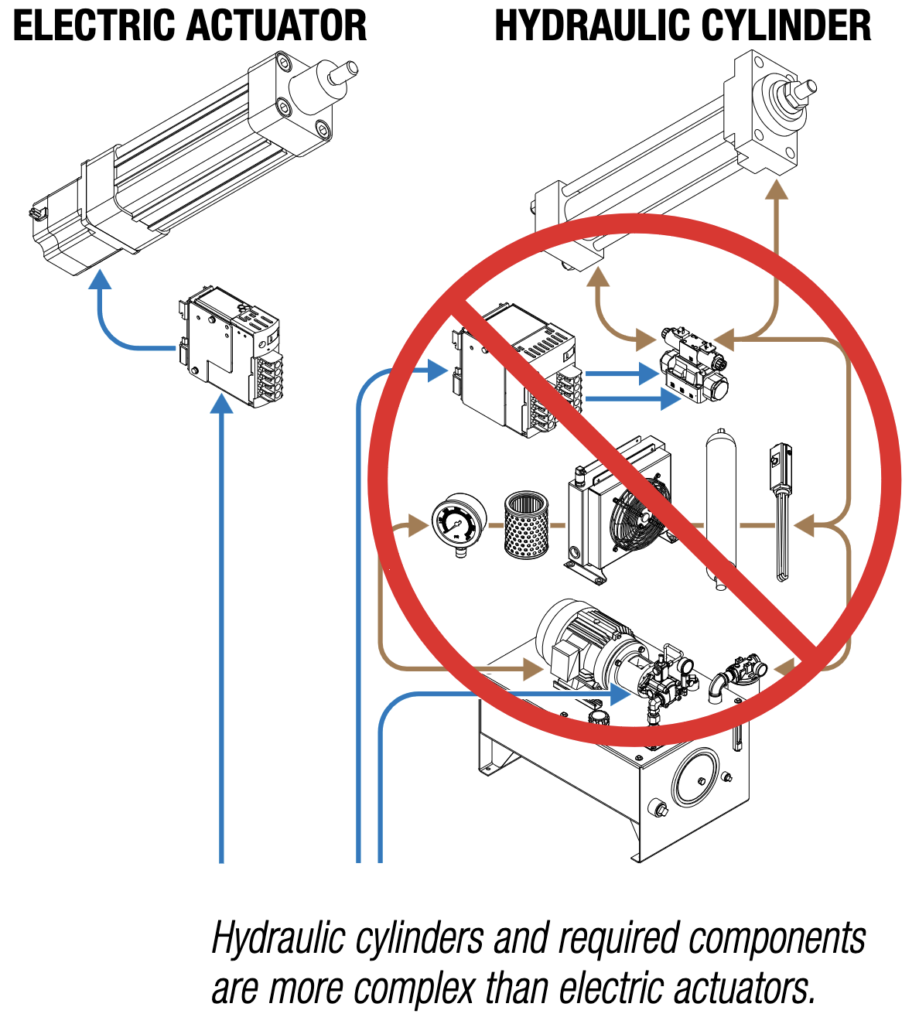

Benefits of Electric Linear Motion Systems over Hydraulic Systems

- Control, Feedback & Data Collection: An actuator’s servo motor/drive system provides precise measurement and control of position, speed, acceleration, and force (torque). This information is available on a continuous basis for tracking and auditing purposes.

- Life and Maintenance: Properly sized and applied electric actuators have a long service life and require minimal maintenance.

- Safety: Light curtain, 2 hand control, guarding configurations available.

- Environmental Concerns: Electric actuators do not contain fluids and therefore do not pose the contamination hazard of hydraulic systems. In addition, temperature fluctuations have less impact on electric actuators.

Designing and Building a Complete Solution

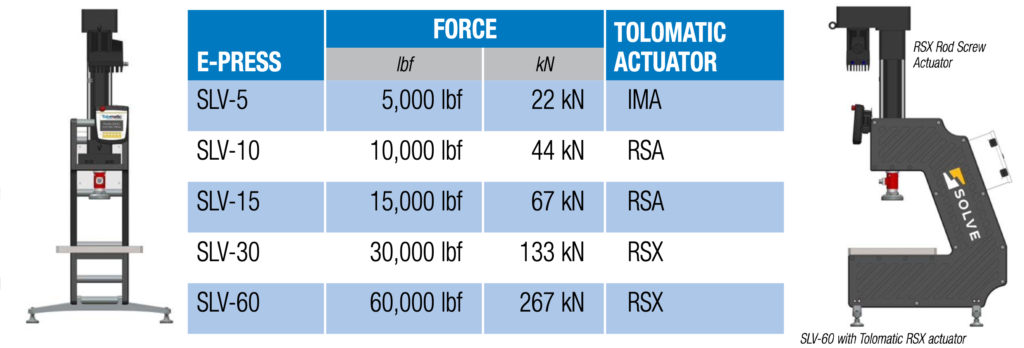

Select an E-Press from proven pre-engineered designs

- Includes electric motor, actuator and fixture

- Pre-engineered designs, stroke configurable

- Specify the motor of your choice with Tolomatic’s Your Motor Here program

Get a question answered or request a virtual design consultation with one of our engineers

Select the motor of your choice and your actuator ships with the appropriate mounting plates and couplers for quick and easy install

Easy three step process to a custom solution

- Tolomatic can collaborate through our local distributor or work with your systems integrator

- Use this service for new systems or difficult retrofit challenges

Begin with |

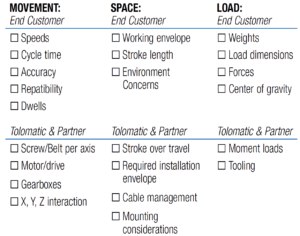

Key Design Considerations |

Quote and Order |

||

Download pre-configured gantry system CAD model

|

Pre-set configurations can be ordered as is or identify any needed modifications: |

Find your Distributor

|

||

|

|

Customer Success Stories

Wheel Bearing Press

The servo controlled RSX actuator allowed the OEM to create quick and easy changeover procedures to accommodate any wheel size.

Powertrain Assembly

Although the hydraulic cylinders could achieve the forces required for the application, they could not deliver the force repeatability and accuracy to achieve a high level of part quality.

Air Bag Production

With a precise servo controlled electric actuator system, the OEM was able to completely eliminate defective parts from the pressing operation.

Ask an Engineer

Ask an Engineer