By adopting electric actuators to replace existing hydraulic cylinders, you’ll be able to improve process control, eliminate leaks and boost overall system efficiency.

Learn about:

- Benefits

- Total Cost of Ownership

- Sizing and Converting Tips

- Application Examples

Download our Ebook on Electric Actuators for Hydraulic Replacement.

Determining Total Cost of Ownership for Electric Actuators

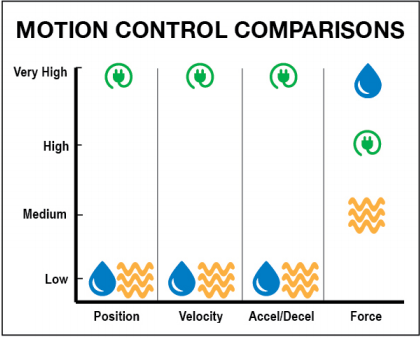

Besides improvements in motion control, there are other factors that contribute to the overall total cost of ownership. In many cases, if all these factors are considered over a reasonable life of the equipment, the electric actuator system will have a lower total cost of ownership.

These factors include:

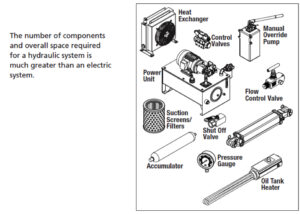

- System components – Hydraulic systems require more components to purchase and maintain.

- Footprint – Although hydraulic cylinders are compact, the overall footprint of an electric actuator system is typically much smaller when factoring in the footprint of the hydraulic power unit, allowing for a more compact and efficient machine design.

- Life – The life of electric actuators can be estimated with an L10 calculation & dynamic load rating while the life of hydraulic cylinders is extremely hard to predict. Electric actuators allow users to better calculate and select an actuator that meets their system life requirements. Download “Calculating Total Cost of Ownership” Infographic.

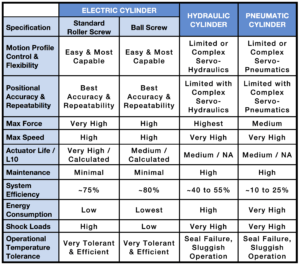

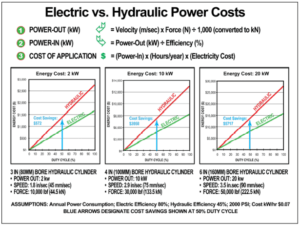

- Efficiency – Electric actuator system efficiency is typically in the 75-80% range while hydraulic systems typically realize around 40-55% efficiency.

- Utility costs – Due to efficiency, hydraulic actuators can consume 2-3 times the amount of electric utility each and every year. Download “Electric vs. Servo-hydraulic vs. Hydraulic Actuators” Infographic.

- Maintenance – When you replace a hydraulic cylinder system with electric actuators, you have a lot less maintenance to deal with — especially regarding seals. Due to wear, temperature, and other factors, seal integrity will diminish and performance along with it.

- Temperature – With high / low temperature grease, electric actuators can operate in temperature extremes with minimal effect on performance.

- Leaks and environmental concerns – Only a matter of time before hydraulic systems will leak. Leaks can be safety hazards as well as contribute to many environmental concerns.

- Data collection – Servo systems used with electric actuators provide position, velocity, and force/torque data at all times to the control system and better monitor processes.

- Other factors – Noise, shock loads, side loads

Replacing Hydraulic Cylinders with Electric Actuators Helps You Save With Lower Total Cost of Ownership

Hydraulic cylinders, known for their high force at an affordable cost, have been widely used in factory automation equipment and other special automation equipment for decades. Hydraulics are rugged, relatively simple to deploy and provide a low cost per unit of force.

Electric rod actuators (cylinders) also have very large force capacities and offer improved system flexibility, precision & reliability. These advancements in electric rod actuators have created an ongoing debate over which technology, hydraulic cylinders or electric actuators, offers the best overall solution. Download Tolomatic’s paper on the pros & cons of Electric Actuator vs. Hydraulic cylinder systems.

How to Calculate Force Requirements to Size Electric Actuators

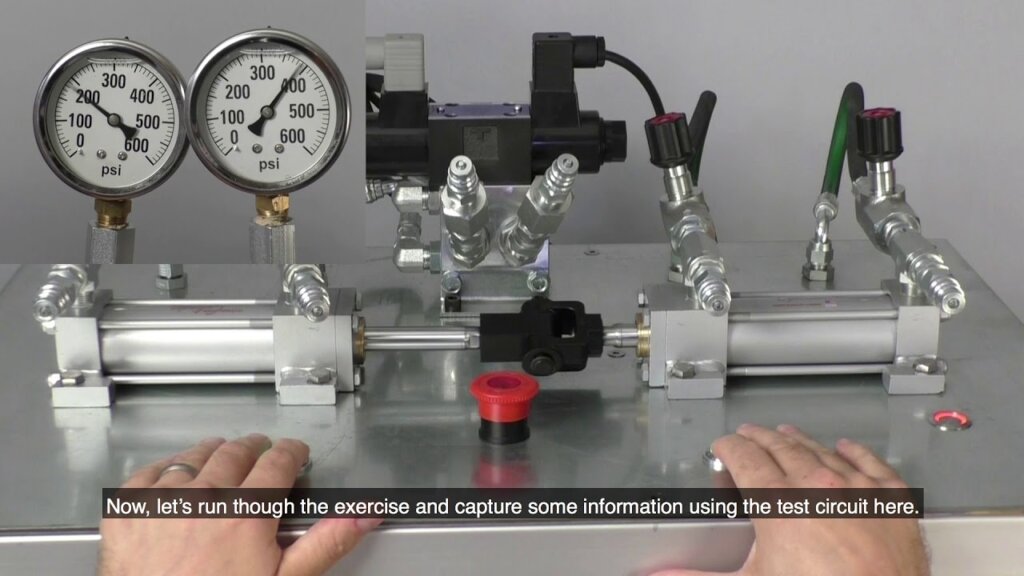

Once the decision has been made to convert from hydraulic cylinder systems to electric actuators, the biggest and most costly mistake that machine designers make is to make an oversimplified force calculation of pressure multiplied by the area of bore size.

Force = Area x Pressure

Since hydraulics are high-pressure systems (typically 2000+ psi or 140+ bar), theoretically they can achieve very high forces, but in practice are typically not deployed near their peak force capabilities. Additionally, the jobs that hydraulic cylinders perform usually do not require full force over the full stroke. In most cases, the force profile will change over the length of the stroke. For example, a pressing application may only have high forces for a very small portion of the stroke and be virtually unloaded during the approach and retract portions. Because of these reasons, it is important to take a little time to make some pressure measurements at the cylinder or valve in order to better determine true application forces. It is quite a simple procedure and Tolomatic has created an easy to follow guide on how to make pressure measurements in a hydraulic cylinder system.

Linear Motion Solutions & Power Transmission Products

Electric Linear Actuators

Industrial linear actuators (rod and rodless), Servo and Stepper control ServoWeld® actuators for robotic resistance spot welding

Servo Linear Actuators

Industrial linear actuators –with integrated servo motor – that readily adapt to drives and controls of your choice with our Drive Integration Tool.

Pneumatic Linear Actuators

Rodless cylinders — band-type and cable cylinders, linear slides and magnetically coupled cylinders and slides Rod cylinder slide thrusters

Power Transmission

Industrial power transmission products including roller screws, gearboxes, brakes and clutches

Tools

Get a question answered or request a virtual design consultation with one of our engineers

Select the motor of your choice and your actuator ships with the appropriate mounting plates and couplers for quick and easy install

Tolomatic offers the most capable product line of industrial strength electric actuators

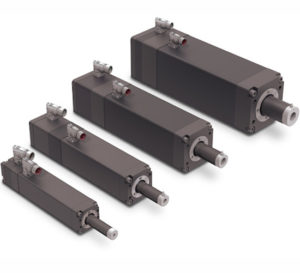

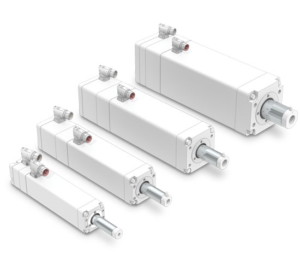

Tolomatic’s expansive and ever-expanding Electric Actuator product line ranges in forces up to 50,000 lbf, ingress protection (IP) options, flexible screw technology (roller or ball screw) options, stainless steel / hygienic options, and compact integrated servo actuator options. With Tolomatic’s very popular Your Motor Here program, just about any 3rd party servo motor can be mounted to one of our actuators.

Products

Hydraulic-class electric linear actuators that are roller screw driven, and provide extremely high forces, precision, and long life. Ideal for hydraulic replacement. Forces up to 66,000 lbf (294 kN).

Electric rod actuator integrated with a servo motor in a single, compact design that integrates with 3rd party drives and accessories. Forces up to 8,044 lbf (35.8 kN).

316 stainless steel construction and IP69K rating provide an electric rod style actuator ideal for food, beverage, and pharmaceutical machines. Forces up to 7,943 lbf (35.3 kN).

Food grade design combines an electric rod actuator and motor into one design with a white epoxy coating for wash-down environments. Integrates with 3rd party drives and accessories. Forces up to 6,900 lbf (30.6kN).

Creating an electric actuator system

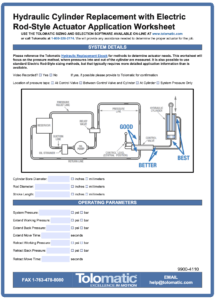

Once the proper measurements have been taken, then the actuator can be sized. To make it easy, Tolomatic has an online sizing software tool to input the motion and force details to select the proper electric actuator for the job. Decisions will need to be made on gearing (ratio), motor size (torque vs. speed), type of power screw (ball or roller screw) and also considering the environment (temperature, contaminants, etc..) that the actuator will be deployed in. We have a helpful Hydraulic Cylinder Replacement Worksheet available that can help in the process too.

Actuator Electrification Applications

Actuator electrification has many benefits that apply to a wide variety of industries. Their clean design means no oil leaks, no workpiece contamination, no environmental risk and minimal downtime due to maintenance. Their consistency means repeatable results that aren’t dependent on fussy hydraulic fluid lines.

When you replace your hydraulic cylinders with electric actuators, the result is better part accuracy and more accurate fill times.

These results can benefit a number of industries, including but not limited to:

Industries

Transportation

Tolomatic actuators are an excellent fit for high duty cycle applications like high-speed train wheel steering or powertrain assembly. Better part quality and increased productivity due to decreased change-over times means electrification is uniquely beneficial for these applications.

Defense and Security Barriers

One particular Tolomatic customer needed help with the lifting and lowering of a security barrier. Their hydraulic solutions were leaking, noisy, and inconsistent — so they were replaced by an electric actuator that helped stop both noise and efficiency issues while making it easier for the barrier to function in harsh temperatures.

Automotive

Electrification offers benefits across the automotive industry, offering improved efficiency for applications like autobody resistance spot welding, air bag deployment, wheel bearing, EV battery tray welding and beyond.

Food Processing

Accuracy and hygienic design are the name of the game with electric actuators in food processing applications — sorting sides of beef, slicing cheese and more.

Success Stories

Product Family: Electric

Product Used: RSA50

Application Description

Filling machine that requires frequent container changes and wash-down

Product Family: Electric

Product Used: RSA

Product Family: Electric

Product Used: ERD20

Product Type: Standard

Metal Fabrication

Force feedback, used to compensate for tolerances in wall thickness and the welded seam location, can help a machine designer reduce scrap in tube welding applications by 80 percent. Other metal fabrication processes can also benefit from electrification, for example an RSX Extreme Force Electric Linear Actuator helped improve the efficiency of a Wheel Bearing Press by 40%.

Timber Processing

Electric actuators are a robust, long-lasting alternative to hydraulics used to position machine rollers on planers. A modified Tolomatic RSA64 HT with roller screws and IP67 seals helped a manufacturer improve efficiency while protecting their actuator from on-the-job contaminants.

Plastic Injection Molding

OEMs often need more efficient control for their plastic injection molding applications. We’ve helped pharmaceutical and medical OEMs with Aseptic Plastic Injection Molding solutions that both fit and performed better than hydraulics.

Tire Manufacturing

Some of the main tire manufacturing companies are currently mandating conversion from hydraulic to electric. For many manufacturers, it’s easier to stay ahead of change than falling behind competition for many applications including tire inspections and tire geometry.

Guides

Ask an Engineer

Ask an Engineer