Achieve better quality welds with electric servo actuators

By Tolomatic on April 2, 2019

Car buyers demand top quality and durability in their vehicles. Automobile manufacturers strive to meet and even exceed these demands. The welds that hold a car’s body together are fundamental to the vehicle’s quality, so it’s essential that weld quality is the best.

Car buyers demand top quality and durability in their vehicles. Automobile manufacturers strive to meet and even exceed these demands. The welds that hold a car’s body together are fundamental to the vehicle’s quality, so it’s essential that weld quality is the best.

Robots are often used in auto body welding because they’re fast and consistent. When it comes to controlling the weld gun, an automobile manufacturer has a choice: use a pneumatic actuator or an electric integrated servo linear actuator. An electric servo actuator will provide better weld quality, consistently.

For a thorough review of the advantages of electric servo actuators in automotive resistance spot welding (RSW), see our white paper, Servo spot welding offers superior performance and lower lifetime costs for auto manufacturing.

The advantages: electric servo actuators for robotic RSW

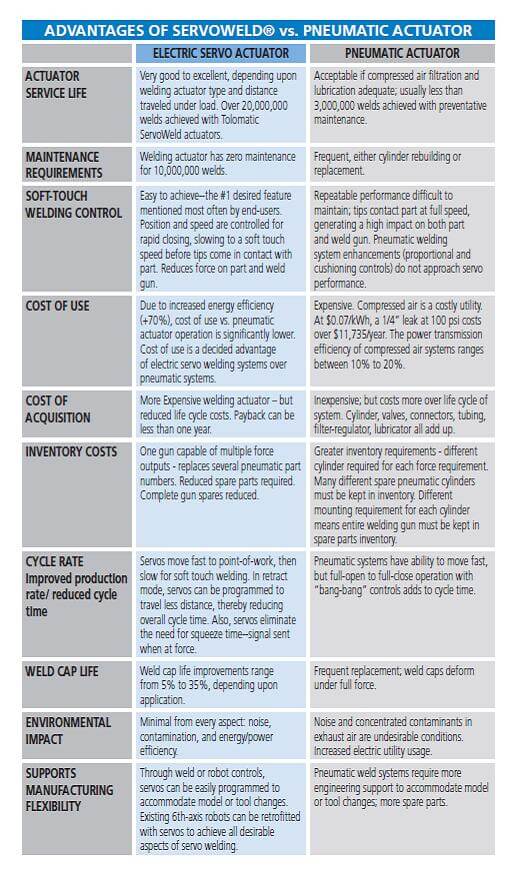

The effectiveness of a robotic spot welder depends on its end effector – the weld gun that joins parts together. In turn, the effectiveness of the weld gun depends on the linear actuator that controls its action. Electric actuators for resistance spot welding offer crucial advantages over pneumatic cylinders.

Weld quality

- Force–Electric actuators deliver consistent force to the weld tips, creating consistent welds. Pneumatic cylinders may deliver varying force due to fluctuations in

air pressure.

air pressure. - Weld tip life—An electric welding actuator doesn’t subject weld tips to excessive wear from burn-through. Weld tips deliver consistent welds for a longer time.

- Consistency—Because servo actuators provide excellent control of variables like clamping force and current, they consistently produce better quality welds. With pneumatic actuators, fluctuating force to the weld tips can lead to burn-through at one extreme and weak welds at the other.

- Changeover—Because electric integrated servo actuators are fully programmable, they can adapt accurately as vehicle requirements change. Pneumatic systems must be adjusted through trial-and-error, yielding less-than-ideal results.

Productivity

- Welds per minute—An electric servo actuator opens the weld tips just enough to move to the next position. Pneumatic actuators set weld tips back to their fully open position after each weld, making them slower.

Cost

- Lower life cycle cost—In the long run, an electric welding actuator is lower cost than a pneumatic actuator because it is faster, longer lasting, more energy efficient and requires much less maintenance.

Our solutions

We offer our ServoWeld® product line of integrated servo actuators specifically designed for automotive body-in-white robotic resistance spot welding. ServoWeld actuators combine servo mot or technology in a powerful high-force actuator for a compact profile and faster resistant spot weld cycles. The ServoWeld line includes:

or technology in a powerful high-force actuator for a compact profile and faster resistant spot weld cycles. The ServoWeld line includes:

GSWA integrated servo actuators — GSWA33, GSWA33 guided, GSWA44 and GSWA04 models. These actuators incorporate standard roller screw technology for a variety of resistance spot welding gun applications (pinch guns, X guns, C guns).

Download the GSWA brochure.

SWA/SWB servo actuators — lightweight, compact and designed to work with smaller resistance spot welding robots. The ServoWeld Advanced (SWA) actuator incorporates our most advanced roller screw technology and delivers the maximum number of welds. The ServoWeld Base (SWB) actuator uses an alternate roller screw design to provide long life at a more economical price.

Download our SWA/SWB brochure.

Watch our ServoWeld video.

Learn more

For a thorough review of the advantages of electric welding actuators for RSW, see our white paper, Servo spot welding offers superior performance and lower lifetime costs for auto manufacturing.

Ask an Engineer

Ask an Engineer