Acme, ball and roller screws for electric linear actuators

By Igor Glikin on February 7, 2017

When you’re specifying a screw-driven electric linear actuator, you’ll need to consider the type of screw that best meets the needs of your specific application. Some manufacturers give you a choice so you can tailor the device precisely, and that’s a good thing since applications differ widely.

When you’re specifying a screw-driven electric linear actuator, you’ll need to consider the type of screw that best meets the needs of your specific application. Some manufacturers give you a choice so you can tailor the device precisely, and that’s a good thing since applications differ widely.

The basic types you’ll have to choose from are roller screws, ball screws and acme screws. There’s quite a lot a machine designer needs to know about these electric actuator screw types and how to select the right one. We offer a guide that helps your decision-making.

Roller Screws

Roller screw actuators are high force linear actuators that can achieve forces exceeding 50,000 lbf (225.5kN). Because of their high-force capabilities, these electric linear actuators are now used instead of hydraulic cylinders in many applications because they offer programmable motion control and lower cost of ownership.

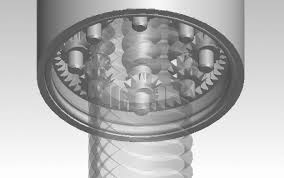

These screws (also called planetary roller screws) have triangular-shaped threads that transmit force to multiple threaded rollers in the nut. Their high force transmission capabilities result from the fact that the rollers have significant contact with the screw threads. These screws and the actuators they power are long-lasting, accurate, capable of high speeds and quick acceleration, and require little maintenance.

They are available in many diameters and leads.

Ball Screws

Ball screws actuators are moderate-to-high force linear actuators and are popular since they offer good performance at an affordable purchase price.

Ball screws actuators are moderate-to-high force linear actuators and are popular since they offer good performance at an affordable purchase price.

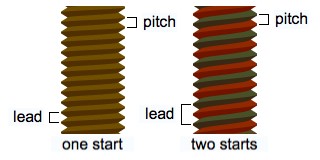

Ball screws get their name from the re-circulating ball bearings that fit between the screw and nut threads. The ball bearings transmit force and relative motion efficiently as they roll through one or more circuits in the nut. Like roller screws, ball screws are available in many leads and diameters.

Ball screw actuators have moderately high thrust capabilities and predictable service lives. On the downside, some ball screws can be back driven easily (depending on the lead), and most produce an elevated level of noise in operation. They’re ideal for applications that require high duty cycles, moderately high thrust, and high speed.

Acme Screws

Acme screw actuators operate quietly and are usually low cost. Acme screws come in a variety of leads and diameters to fit many applications. Nuts can be made f rom metals (which require lubrication to overcome friction) and self-lubricating plastics.

rom metals (which require lubrication to overcome friction) and self-lubricating plastics.

Acme screws are very strong due to their trapezoidal tooth form; however, they can be very inefficient. Acme screws need high motor torques to drive them because of the friction inherent in the sliding action between screw and nut. Because of this friction and thread geometry, acme screws can reduce or eliminate back driving.

An acme screw is a good choice in linear actuator applications that require low speeds and duty cycles. Because so many variables (nut material, environmental factors and the demands of the application) affect the wear characteristics of acme nuts, it can be difficult to predict the service life of these screw/nut systems.

Insist on choice

The three screw types differ in their capabilities. Each has advantages and disadvantages depending on the parameters of an application. We recommend you look for an actuator manufacturer who offers you a range of screw type choices so you get an actuator that’s tailored to your needs.

Learn more

Download our guide, Which screw? Picking the right technology, for an overview of the advantages and disadvantages of each screw type.

Ask an Engineer

Ask an Engineer